11 Degree Taper Drill Bits: Precision Engineering for Demanding Applications

When it comes to achieving precise and stable drilling results, 11 Degree Taper Drill Bits are a top-tier solution for professionals across industries. These drill bits offer a reliable connection with drilling rods, superior wear resistance, and consistent penetration rates—making them ideal for tough rock formations and demanding environments. In this article, we explore the features, benefits, and key applications of 11 Degree Taper Drill Bits, ensuring you understand why they are an essential part of modern drilling systems.

What Are 11 Degree Taper Drill Bits?

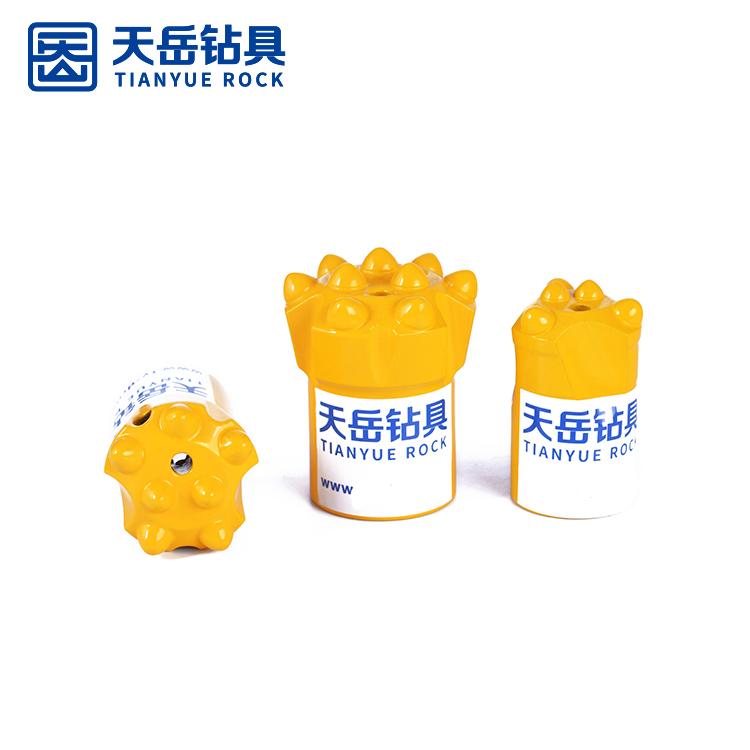

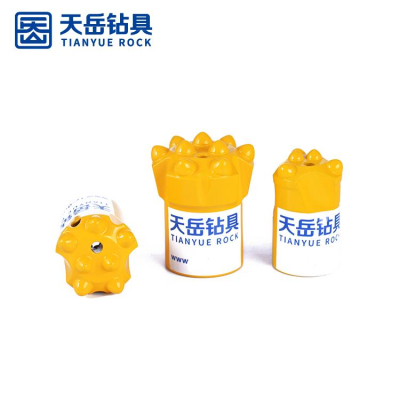

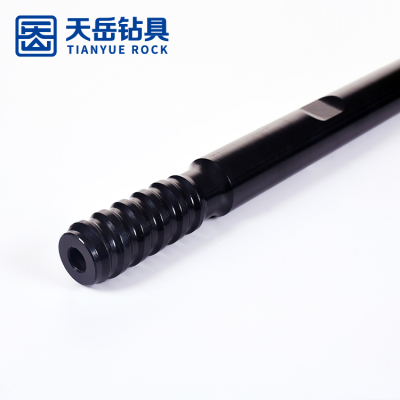

11 Degree Taper Drill Bits are specialized tools designed with an 11-degree taper angle that connects seamlessly with matching tapered drill rods. This configuration creates a tight and secure interface, minimizing bit slippage and improving energy transfer from the drill to the bit. Whether you're drilling for mining, tunneling, or quarrying, the unique geometry of 11 Degree Taper Drill Bits delivers optimal drilling efficiency.

Unlike straight shank bits, 11 Degree Taper Drill Bits enhance rotational stability and reduce the risk of jamming or wobbling, especially when working with handheld or pneumatic rock drills. Their robust construction and precision-tapered ends make them a go-to solution for short-hole drilling and high-impact tasks.

Core Features of 11 Degree Taper Drill Bits

Tapered Design for Strong Fit

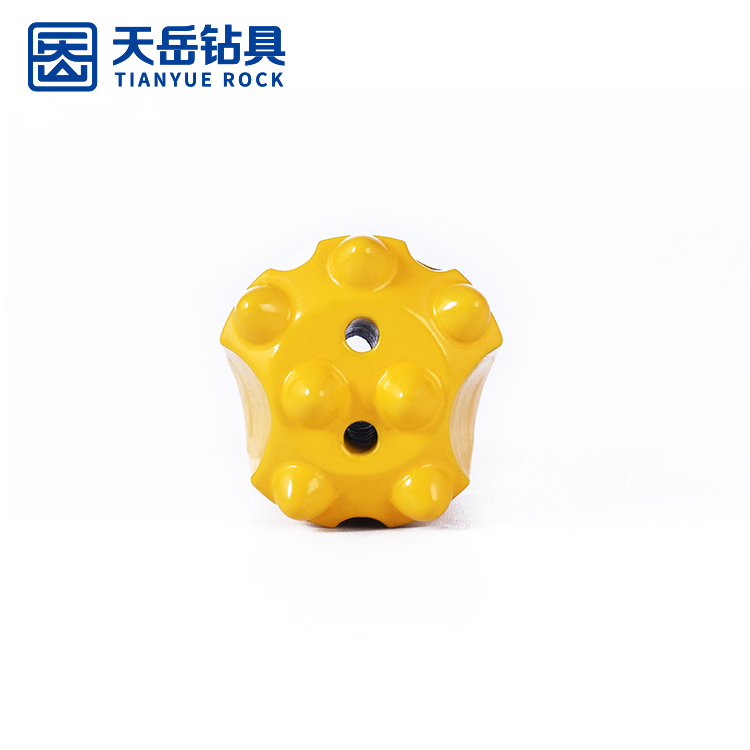

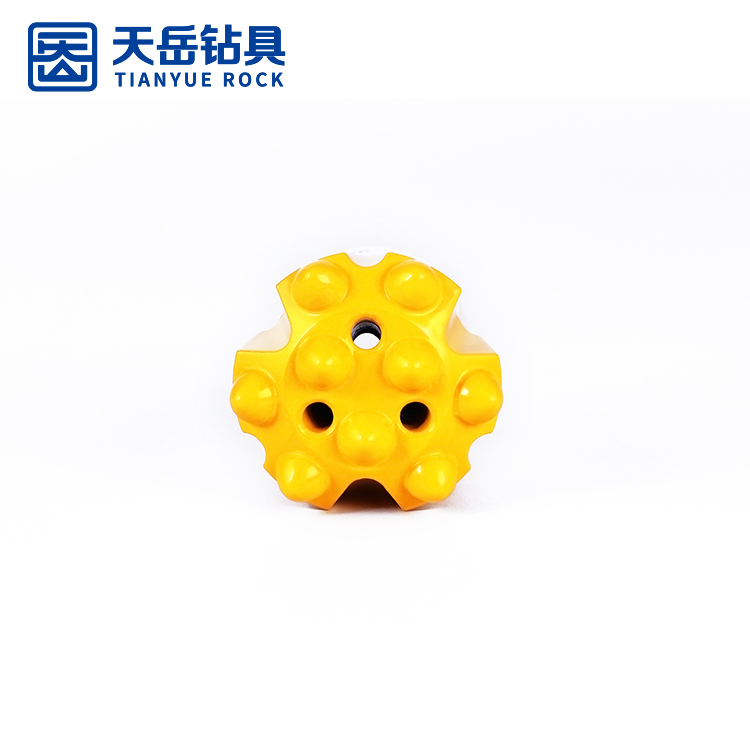

The 11-degree taper ensures a snug fit between the bit and the drill rod, eliminating gaps that cause power loss or damage during drilling. This results in more efficient rock penetration and less mechanical stress.

High-Strength Materials

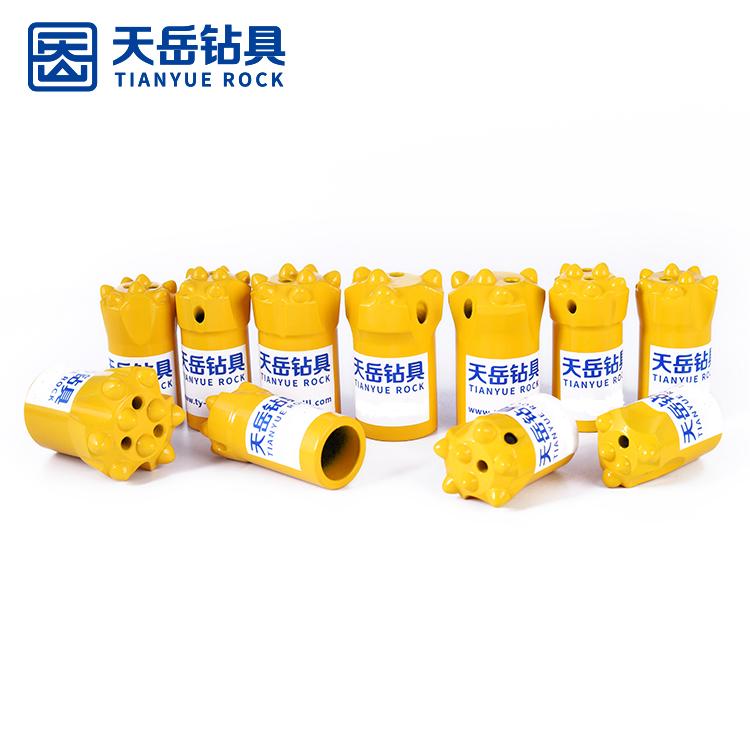

Most 11 Degree Taper Drill Bits are crafted from premium alloy steel with carbide inserts, offering high resistance to wear, heat, and shock. This ensures long-term durability and lower replacement frequency.

Interchangeable Bit Heads

These bits are often designed with different head shapes such as chisel, cross, or button tips. Each variation offers tailored performance depending on the hardness of the rock and desired hole quality.

Optimized Flushing System

Many 11 Degree Taper Drill Bits are engineered to accommodate air or water flushing systems, which improve debris removal and prevent overheating during continuous drilling.

Why Choose 11 Degree Taper Drill Bits?

Choosing 11 Degree Taper Drill Bits gives professionals a powerful edge in performance and reliability. Below are the key reasons why these bits stand out in the drilling industry:

Enhanced Energy Transfer:

The 11-degree taper creates a firm mechanical link between the bit and the rod, ensuring that impact energy is transmitted directly to the rock. This minimizes energy loss and boosts productivity.

Superior Control and Accuracy:

With better alignment and rotational control, 11 Degree Taper Drill Bits allow for straighter holes and improved drilling accuracy—critical for mining and geotechnical operations.

Reduced Bit Slippage:

The taper angle is optimized to prevent accidental detachment during high-impact drilling. This provides peace of mind and prevents costly tool loss or downtime.

Longer Service Life:

Due to their durable construction, 11 Degree Taper Drill Bits endure more drilling cycles without chipping or deformation, resulting in lower operating costs.

Versatile Applications:

These bits are suitable for a range of rock hardness levels and can be used in both manual and mechanized drilling setups.

Applications of 11 Degree Taper Drill Bits

11 Degree Taper Drill Bits are widely used in:

Mining and Ore Extraction

Efficiently drill blast holes or sample cores in hard or medium-hard rock. The bit’s design allows deep penetration and minimal tool wear.

Tunneling and Underground Construction

Ideal for drilling small-diameter holes for supports, reinforcements, or blasting in confined underground conditions.

Hydropower and Dam Engineering

Used to drill anchor holes in concrete or bedrock for structural reinforcement in dam or hydropower construction.

Quarrying and Stone Splitting

Enables accurate hole drilling for splitting natural stone blocks, ensuring minimal waste and clean breaks.

Geotechnical Investigation

Assists engineers in drilling boreholes for soil and rock analysis, ensuring foundation safety and environmental assessments.

Best Practices for Using 11 Degree Taper Drill Bits

Choose the Correct Tip Style:

Use button bits for hard rock, chisel bits for medium rock, and cross bits for fractured formations.

Monitor Wear and Tear:

Regular inspection ensures early detection of wear on carbide tips or taper surfaces, reducing risks during drilling.

Use Compatible Taper Rods:

Always pair 11 Degree Taper Drill Bits with corresponding taper rods to ensure safety and performance.

Employ Proper Lubrication and Cooling:

Utilize air or water flushing systems to extend the life of the bit and maintain drilling speed.

Correct Hammer Pressure:

Adjust the impact force based on the rock condition to avoid premature bit damage or reduced drilling performance.

Final Thoughts

11 Degree Taper Drill Bits are a cornerstone of high-performance drilling in demanding applications. Their unique taper angle, robust build, and precise energy transfer capabilities make them an industry favorite for professionals who need results they can trust. Whether in a remote mining site or a complex infrastructure project, 11 Degree Taper Drill Bits consistently deliver the accuracy, durability, and efficiency required for top-tier operations.