When it comes to large-scale infrastructure, nothing is more critical than a stable foundation. And behind every successful foundation project are high-performance foundation drilling tools. Whether you’re working in urban construction, bridge engineering, or energy infrastructure, the quality of your foundation drilling tools can make or break your project—literally.

In this guide, we’ll explore what makes the best foundation drilling tools, what to look for when sourcing them, and why upgrading your tooling now can significantly increase drilling speed, reduce wear, and cut overall costs.

Why High-Quality Foundation Drilling Tools Matter

The success of any drilling operation begins underground. Choosing the right foundation drilling tools improves:

Drilling efficiency

Tool lifespan

Borehole precision

Cost-per-foot reduction

Poor-quality tooling leads to breakdowns, inaccurate piles, and costly downtime. That’s why contractors, engineers, and construction managers consistently ask: Which are the best foundation drilling tools for rock, clay, or mixed ground conditions?

Types of Foundation Drilling Tools You Should Know

Understanding the different foundation drilling tools helps you make informed, site-specific decisions:

1. Augers

Perfect for soft to medium soil. Flighted augers efficiently remove spoils and are available in both continuous and sectional types.

2. Core Barrels

Essential when drilling into rock or reinforced concrete. Equipped with carbide teeth or bullet bits, they handle tough strata with ease.

3. Drilling Buckets

Ideal for cohesive and granular soils. These foundation drilling tools come in single-cut or double-cut styles and include bottom plates that open to release cuttings.

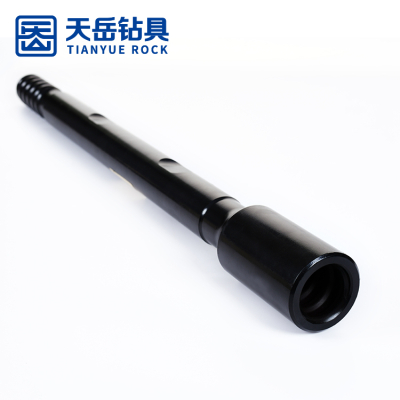

4. Kelly Bars

Kelly bars transmit torque from the rotary drive to the drilling tool. Telescopic and interlocking models are suited for different pile depths.

5. Casing Tools

Support weak soil walls during drilling. Includes casing shoes, drive adapters, and oscillators—all critical in loose or water-bearing layers.

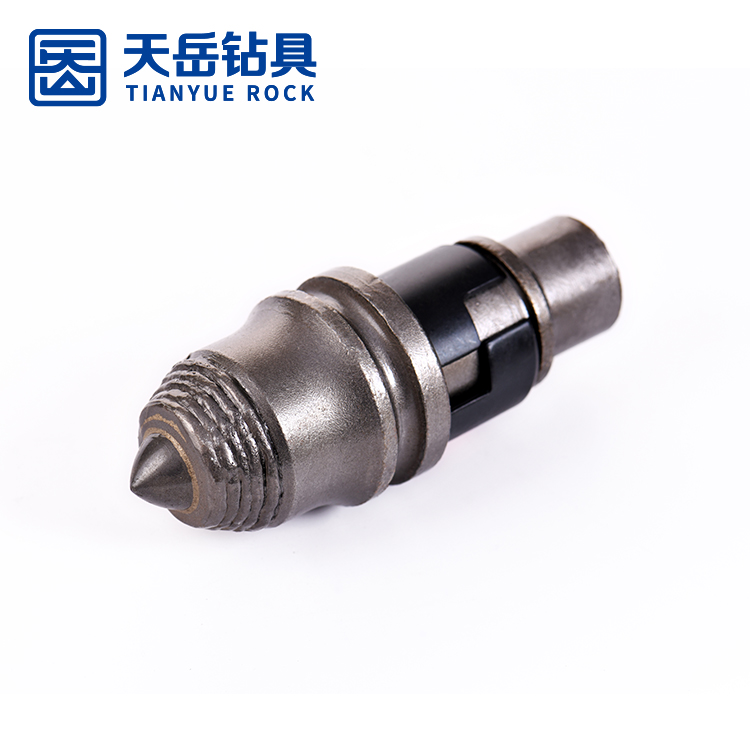

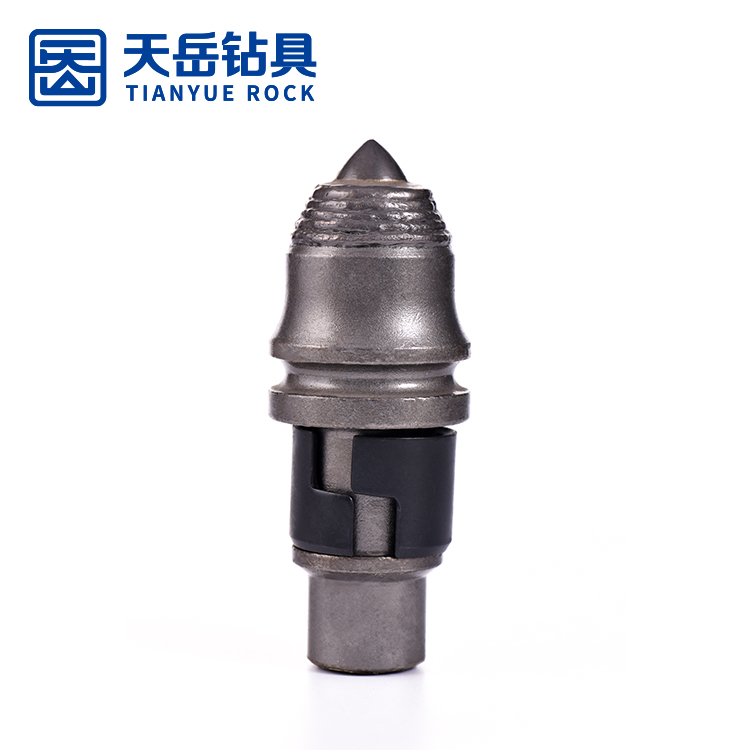

6. Cutting Teeth and Bits

These small but mighty foundation drilling tools are key wear parts that directly impact penetration rate. Options include flat teeth, conical bits, and tapered teeth for various soil hardness.

What to Look for in Premium Foundation Drilling Tools

Not all foundation drilling tools are created equal. Here’s what distinguishes a top-tier supplier:

Wear-Resistant Alloys – Tungsten carbide or high-chromium steels ensure durability.

Precision Engineering – CNC-manufactured tools guarantee optimal performance and fit.

Compatibility – Tools that match Bauer, Soilmec, Casagrande, or IMT rigs ensure seamless integration.

Customization – Ground conditions vary. The best suppliers offer customized tool configurations based on soil reports.

✅ Choosing the right foundation drilling tools isn’t a cost—it’s an investment in uptime, safety, and long-term profitability.

Top Applications for Foundation Drilling Tools

The versatility of foundation drilling tools allows them to be used in:

Skyscraper and bridge foundations

Wind turbine bases

Offshore and nearshore marine piles

Dam, tunnel, and shaft foundations

Micropile and anchor drilling

No matter the project size, having the right foundation drilling tools ensures integrity and speed from the ground up.

How to Extend the Life of Your Foundation Drilling Tools

To protect your tooling investment:

Inspect regularly for wear and cracks

Replace worn teeth before failure

Lubricate moving parts properly

Store in dry, debris-free areas

Choose OEM or high-grade aftermarket parts

Smart maintenance keeps your foundation drilling tools working longer and drilling cleaner.

Why Contractors Worldwide Trust [Your Brand/Supplier]

With years of experience supplying industry-grade foundation drilling tools, [Your Company] understands that performance is non-negotiable. Our tools undergo strict quality control and are engineered for superior penetration, low vibration, and maximum durability.

✔ Global Compatibility

Compatible with leading rig brands like Bauer, Mait, Liebherr, and XCMG.

✔ Custom Solutions

Whether you need conical rock bits or soft-soil augers, we tailor the right foundation drilling tools for your geological profile.

✔ Bulk Supply & Fast Shipping

Need hundreds of buckets or barrels fast? We’ve got inventory and logistics ready to support your timeline.

📞 Get a Quote Today and discover why top contractors choose [Your Brand] for reliable, high-performance foundation drilling tools.

Final Thoughts: Choose Foundation Drilling Tools That Work as Hard as You Do

If you're asking, “What foundation drilling tools do I need for my next big project?” — you're already ahead of the curve. The answer lies in quality, compatibility, and supplier trust. Don’t settle for mediocre equipment that risks your project timeline or safety.

Upgrade to advanced foundation drilling tools designed to outperform, outlast, and deliver results that your clients will notice. After all, every great structure starts with a solid foundation—and that foundation starts with the right tools.