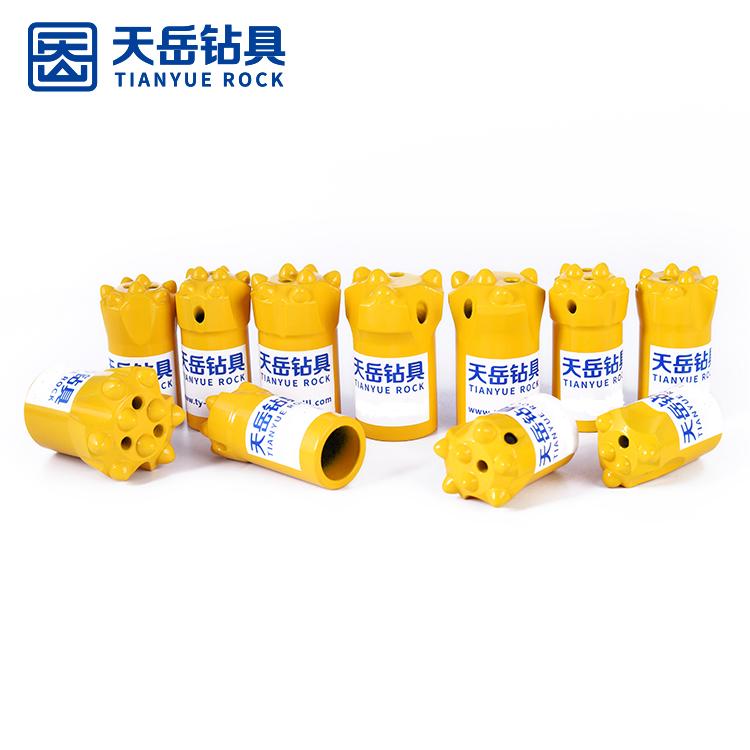

7 Degree Taper Drill Bits: The Reliable Solution for Precision Rock Drilling

In the world of rock drilling, precision, safety, and durability are paramount. Among the many tools available to professionals, 7 Degree Taper Drill Bits stand out as a preferred choice for shallow and medium-depth drilling in hard and semi-hard rock. With a distinct taper angle of 7 degrees, these drill bits deliver optimal coupling strength, reduced slippage, and improved energy transfer. In this article, we’ll delve into the core characteristics, advantages, and applications of 7 Degree Taper Drill Bits, helping you understand why they are vital to mining, tunneling, and construction sectors.

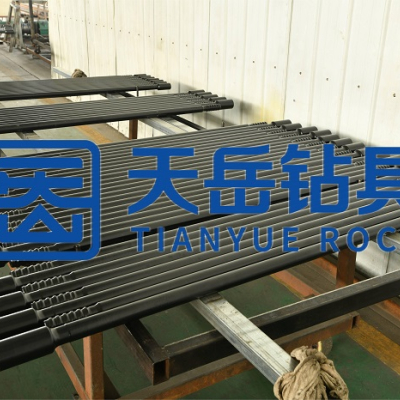

What Are 7 Degree Taper Drill Bits?

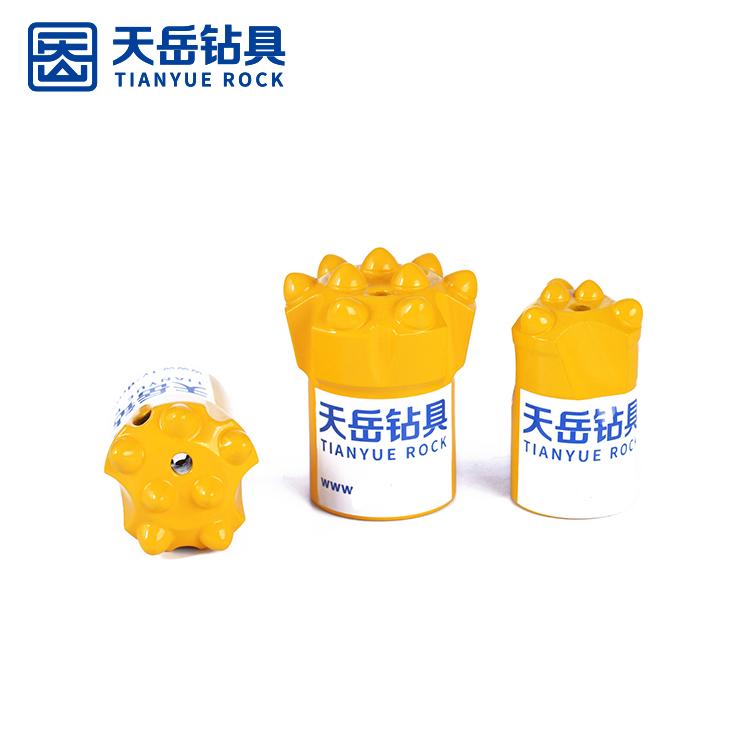

7 Degree Taper Drill Bits are designed with a conical shank that forms a 7-degree angle. This specific angle provides a balanced blend of grip strength and ease of detachment, ensuring efficient torque transmission between the bit and the drill rod. These bits are typically used with pneumatic hand-held rock drills and are suitable for shorter hole drilling tasks where stability and maneuverability are essential.

Compared to higher-degree taper bits, 7 Degree Taper Drill Bits offer tighter engagement, which is ideal for hard rock formations where tool slippage must be minimized. This makes them particularly useful for demanding environments such as mountain excavation, urban foundation work, and open-pit mining.

Core Features of 7 Degree Taper Drill Bits

Optimized Taper Angle

The 7-degree design ensures a strong mechanical lock with the drill rod while allowing for quick tool changes. It offers the ideal balance between holding power and removability.

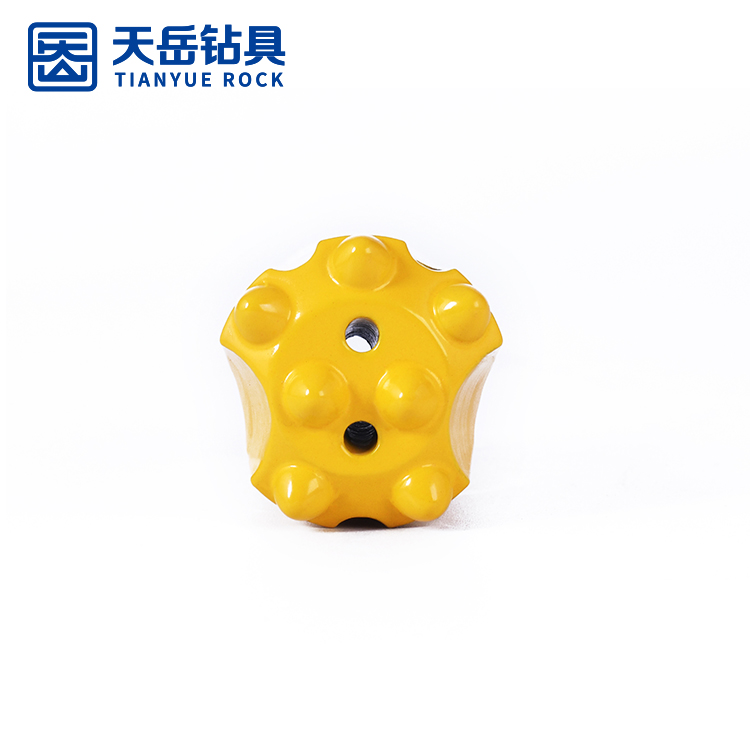

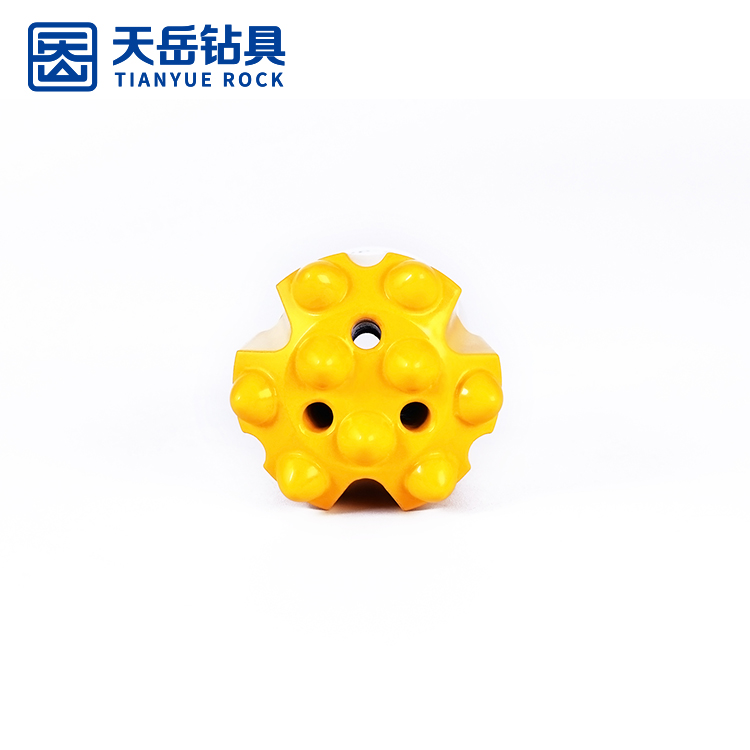

Durable Tungsten Carbide Inserts

Most 7 Degree Taper Drill Bits feature high-grade tungsten carbide buttons or chisel tips that deliver superior hardness and wear resistance, extending the bit’s working life even in abrasive conditions.

Multiple Bit Face Options

Available in chisel, cross, and button bit faces, 7 Degree Taper Drill Bits can be tailored to different rock hardness levels and application requirements.

Compact and Versatile

These bits are well-suited for handheld rock drilling, offering ease of use in confined or rugged environments where mechanized equipment is impractical.

Benefits of Using 7 Degree Taper Drill Bits

Efficient Energy Transmission

With a strong taper fit, 7 Degree Taper Drill Bits transmit percussive energy directly to the rock, minimizing energy loss and improving penetration speed.

Reduced Bit Slippage

The 7-degree angle offers superior retention between bit and rod, drastically reducing the chance of bit disengagement during drilling.

Easy Maintenance and Replacement

The simplicity of the taper connection allows for quick bit changes in the field, reducing downtime and boosting productivity.

Long Service Life

The combination of premium steel bodies and carbide inserts ensures durability even under intense drilling pressures and repeated use.

Low Operating Cost

Thanks to extended bit life and fewer replacements, 7 Degree Taper Drill Bits contribute to lower operational costs over time.

Applications of 7 Degree Taper Drill Bits

7 Degree Taper Drill Bits are widely used across industries that demand reliable and precise rock penetration. Key application areas include:

Mining and Quarrying

Ideal for blast hole drilling, these bits help operators achieve uniform hole sizes and depths in hard and abrasive rock.

Tunneling and Foundation Work

When creating boreholes for rock bolts or reinforcements, 7 Degree Taper Drill Bits offer the stability and accuracy required for structural integrity.

Hydropower and Dam Construction

Used to drill secure anchor points in dam bases and retaining structures where drilling in granite or basalt is common.

Road and Bridge Engineering

Applied in drilling dowel holes and anchorage points in roadbeds and support beams, especially in hilly or mountainous regions.

Geological Exploration

Engineers rely on 7 Degree Taper Drill Bits for preliminary rock sampling and geotechnical testing in exploration zones.

Best Practices for 7 Degree Taper Drill Bits

Match the Bit to the Rock Type

Use chisel bits for soft to medium-hard rock, cross bits for broken rock formations, and button bits for hard rock drilling.

Check Bit Wear Regularly

Inspect carbide tips and taper shanks for signs of wear or cracking. Regrind or replace worn bits promptly to maintain drilling efficiency.

Use the Right Flushing System

Implement air or water flushing to remove cuttings and keep the bit cool during operation.

Pair with Compatible Drill Rods

Always use 7 Degree Taper Drill Bits with matching taper rods to prevent joint misalignment or early tool failure.

Control Impact Force

Avoid excessive hammer pressure, which can prematurely wear the taper connection and reduce bit lifespan.

Final Thoughts

In high-stakes environments where precision and reliability are non-negotiable, 7 Degree Taper Drill Bits offer the perfect solution. Their robust design, high retention capability, and versatility make them indispensable tools for professionals in mining, infrastructure development, and rock excavation. With the right maintenance and proper usage, 7 Degree Taper Drill Bits can significantly enhance your drilling productivity and reduce operational costs.

Choose 7 Degree Taper Drill Bits for your next project, and experience unmatched performance and consistency in rock drilling operations.