T45 Reaming Drill Bits: Precision and Power for Efficient Rock Drilling

When it comes to hard rock drilling in mining, tunneling, and construction projects, T45 reaming drill bits are among the most reliable and effective tools available. Known for their durability, cutting performance, and adaptability to challenging geological conditions, T45 reaming drill bits have become a critical solution for professionals seeking speed, precision, and extended tool life.

What Are T45 Reaming Drill Bits?

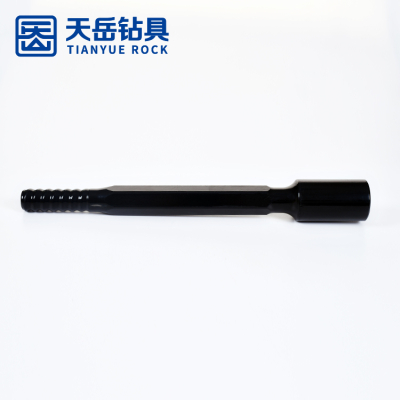

T45 reaming drill bits are designed for enlarging pilot holes during drilling operations in medium to hard rock formations. These bits are typically used in face drilling, bolt hole drilling, and production drilling in both underground and surface mining operations. The "T45" refers to the thread connection standard, which ensures compatibility with T45 drill rods and shanks, delivering high torque transmission and operational efficiency.

Key Features of T45 Reaming Drill Bits

High Wear Resistance

Made from premium-grade tungsten carbide and heat-treated alloy steel, T45 reaming drill bits offer exceptional resistance to wear and fatigue, even in abrasive rock conditions.

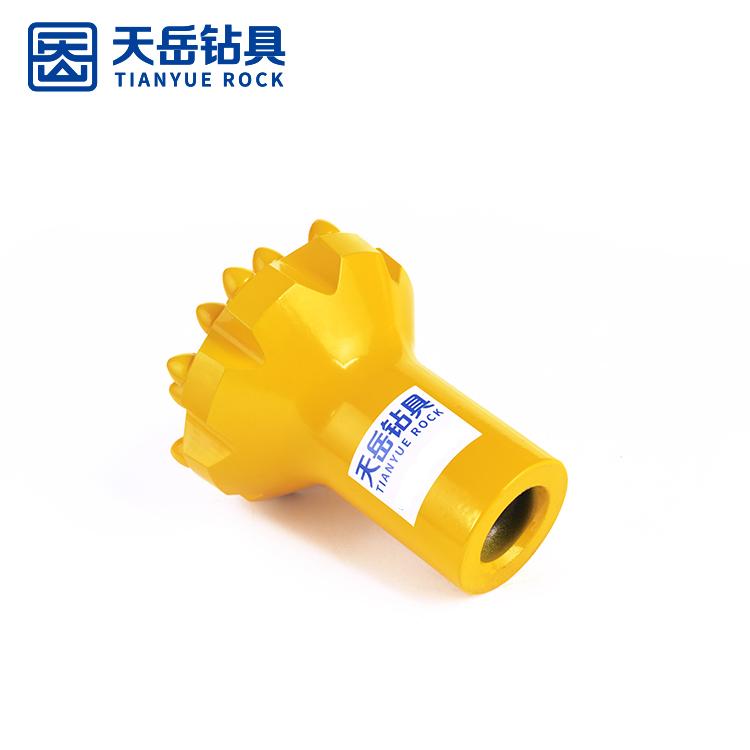

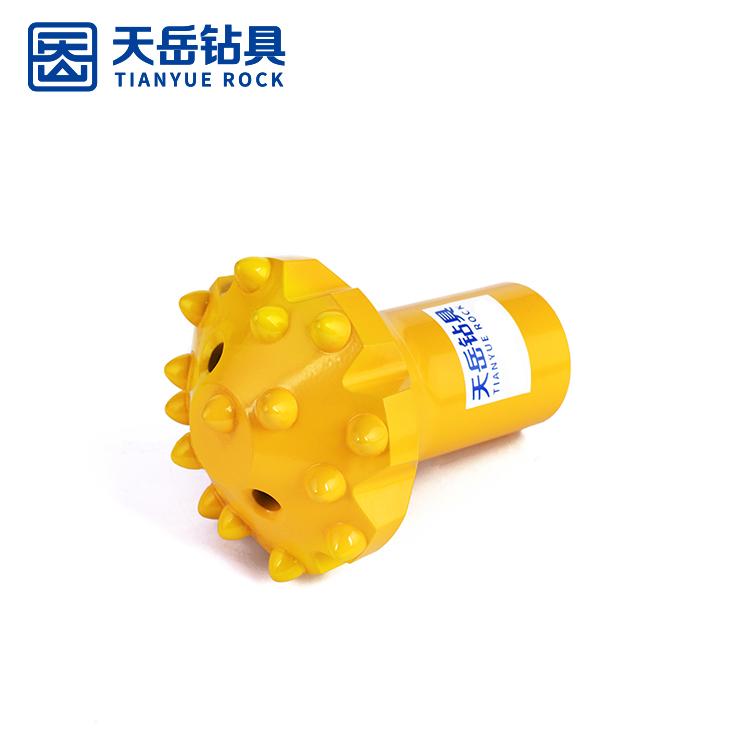

Optimized Cutting Structure

The bit head features symmetrically arranged buttons or inserts to ensure balanced rock fragmentation and smooth reaming action. This reduces vibrations, enhances drilling accuracy, and improves hole straightness.

Threaded Connection

The robust T45 threaded shank ensures secure attachment and minimizes energy loss during impact and rotation, making T45 reaming drill bits a preferred choice in demanding environments.

Customizable Designs

Available in various sizes (typically 76mm to 127mm), face designs (drop center, flat face, ballistic, or semi-ballistic buttons), and button configurations, T45 reaming drill bits can be tailored for different geological requirements and drilling goals.

Applications of T45 Reaming Drill Bits

T45 reaming drill bits are widely used in a variety of sectors, including:

Underground Mining: For reaming pilot holes in ore extraction and tunnel development.

Surface Drilling: In quarrying, bench drilling, and open-pit mine development.

Hydropower and Civil Projects: For foundation and rock bolt hole enlargements.

Tunneling and Infrastructure: Used in road, subway, and rail tunnel construction.

In all these sectors, T45 reaming drill bits ensure reduced drilling time, improved safety, and optimized operating costs.

Advantages of Choosing T45 Reaming Drill Bits

Improved Drilling Efficiency

With a strong cutting capability and better rock penetration rate, T45 reaming drill bits contribute to shorter cycle times and faster project completion.

Extended Service Life

Thanks to high-grade materials and precision engineering, these drill bits maintain performance over extended periods, reducing the need for frequent replacements.

Enhanced Hole Accuracy

The stable design of T45 reaming drill bits ensures that the enlarged hole maintains its shape and direction, which is crucial for bolt installation and blast design precision.

Lower Operating Costs

Increased durability and efficiency translate to fewer consumables and less downtime, saving both labor and material costs over the project lifespan.

Why T45 Reaming Drill Bits Are the Industry Standard

In environments where time, accuracy, and cost-efficiency are vital, T45 reaming drill bits deliver unmatched performance. Leading drilling contractors and mining companies rely on these tools for consistent results under pressure. The T45 standard, combined with cutting-edge bit design, supports high productivity in even the toughest rock formations.

Conclusion

Whether you're involved in mining, construction, or geotechnical engineering, T45 reaming drill bits provide a high-performance solution for enlarging boreholes with speed and precision. Their strength, versatility, and consistent performance make them essential tools in any professional driller’s arsenal. For projects that demand reliability and efficiency, T45 reaming drill bits are the smart choice that delivers results.