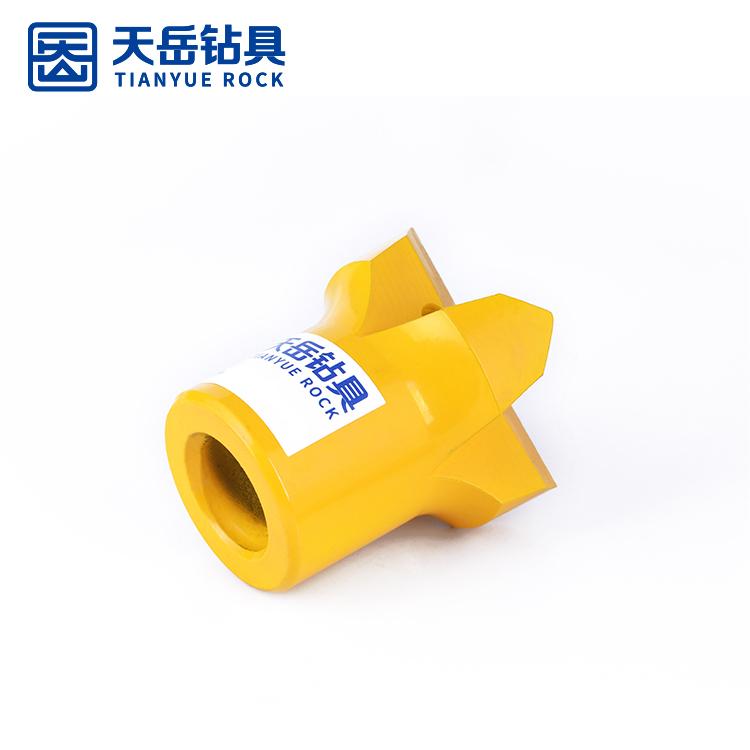

High-Performance Rock Tools for Furnace Cross Bit Applications

Rock Tools For Furnace Cross Bit play a critical role in demanding drilling environments, especially in metallurgical operations and refractory maintenance where precision and heat resistance are non-negotiable. Specifically designed for furnace tapping and maintenance drilling, these specialized Rock Tools For Furnace Cross Bit ensure efficiency, durability, and safety during high-temperature operations.

What Are Rock Tools for Furnace Cross Bit?

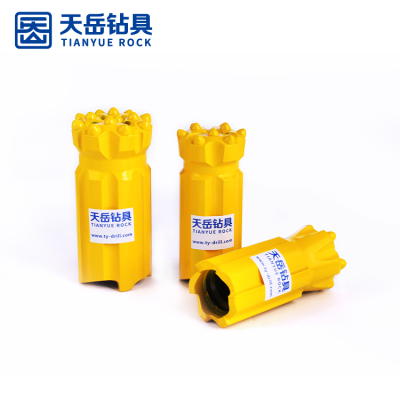

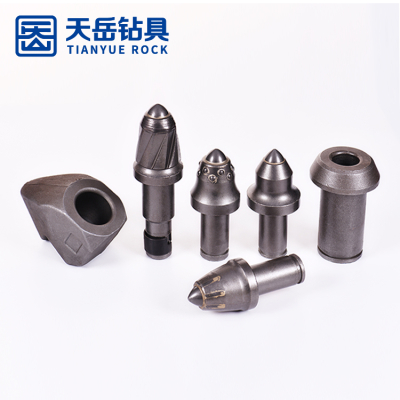

Rock Tools For Furnace Cross Bit are specialized drilling components engineered to perform in extremely abrasive and high-temperature conditions. The Furnace Cross Bit itself features a cross-shaped tungsten carbide insert that is ideal for controlled, straight-hole drilling through dense and heat-affected materials such as slag, brick lining, and high-hardness refractories found in industrial furnaces.

Matched with precision-made rock tools such as drill rods, shank adapters, and coupling sleeves, Rock Tools For Furnace Cross Bit enable operators to carry out maintenance drilling with exceptional control and minimal equipment wear.

Key Features of Rock Tools For Furnace Cross Bit

Heat-Resistant Materials: Constructed using advanced alloy steels and heat-treated tungsten carbide to withstand furnace-level temperatures.

Optimized Thread Interface: Designed for perfect compatibility between the Furnace Cross Bit and its supporting rock tools, ensuring efficient energy transfer.

Superior Wear Resistance: Carbide tips and surface-hardened tool steel offer prolonged service life in abrasive conditions.

Precision Drilling Performance: The cross design of the bit delivers excellent hole straightness and reduces deviation—critical in furnace lining operations.

Safety and Reliability: Each component of the Rock Tools For Furnace Cross Bit system is manufactured with high tolerances to prevent malfunction under stress.

Applications of Rock Tools For Furnace Cross Bit

Rock Tools For Furnace Cross Bit are primarily used in:

Steel Plant Furnaces: Drilling through hardened slag or refractory brick linings for tapping or maintenance purposes.

Non-Ferrous Metallurgy: Used in copper, lead, and aluminum smelters for repairing smelting chambers or cleaning blocked tap holes.

Cement Kilns: Assists in kiln maintenance by providing accurate drilling for material removal or inspection ports.

Industrial Boilers: When high-temperature linings require modification or clearing, Furnace Cross Bit tools offer unmatched performance.

The combination of these Rock Tools For Furnace Cross Bit ensures precision and durability in the harshest industrial environments.

Why Choose Rock Tools for Furnace Cross Bit Drilling?

Choosing premium Rock Tools For Furnace Cross Bit means prioritizing accuracy, operational efficiency, and worker safety. These tools are engineered to deliver optimal penetration rates without compromising structural integrity, even in extreme heat and pressure.

Their consistent performance reduces downtime, increases throughput during furnace maintenance, and minimizes tool replacement frequency—leading to significant cost savings over time.

Conclusion

In high-heat, high-hardness drilling environments, only specialized solutions can deliver consistent results. Rock Tools For Furnace Cross Bit offer an ideal combination of heat resistance, drilling precision, and structural durability. Whether for emergency furnace repairs or routine industrial maintenance, these tools are built to outperform under pressure.

For industries that demand precision and strength, Rock Tools For Furnace Cross Bit are the trusted choice—engineered for the most extreme drilling challenges.

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

![Rock Tools For Furnace Cross Bit Rock Tools For Furnace Cross Bit]()

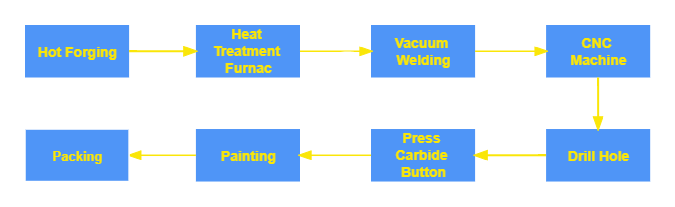

Bit process flow

![Rock Tools For Furnace Cross Bit Rock Tools For Furnace Cross Bit]()