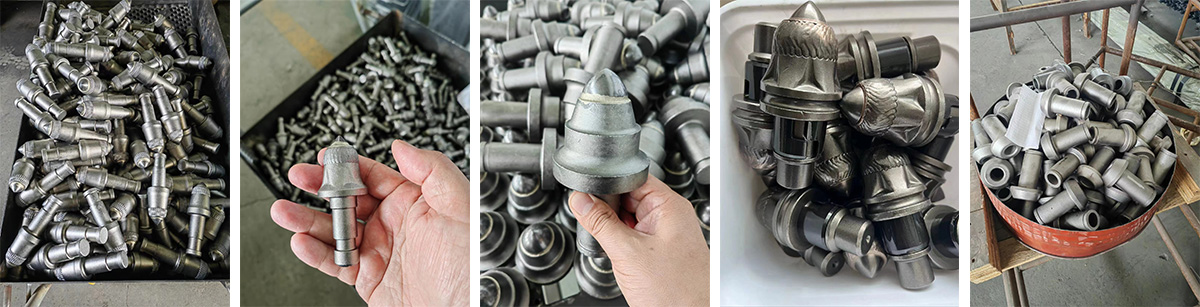

Engineering rotary digging teeth are composed of three parts: main alloy (tungsten carbide alloy), matrix (high-quality alloy structural steel), and circlip (spring steel). The main alloy is effectively welded with the parent body through advanced brazing technology, and the shear strength of the brazed seam is ≥180MPa. The mother body rod is equipped with a special groove structure for placing the circlip. The circlip is mechanically assembled and connected to the mother body. Through the tensioning force of the circlip, the mounting gear seat can effectively grasp the rotary digging teeth.

Wear-resistant layer:

We use imported wear-resistant welding wire, which has good bonding performance with the tooth body, strong wear resistance, and good surfacing performance. The surfacing thickness can be thickened as needed.

Alloy aspects:

Engineering Rotary Cutting Teeth: A Comprehensive Guide to Precision Cutting Tools

Engineering rotary cutting teeth are crucial components in many industries, especially in manufacturing, machining, and construction. These specialized tools are designed for cutting, shaping, and finishing materials with high precision. In this guide, we will explore the importance of engineering rotary cutting teeth, their applications, types, and how they contribute to enhanced productivity and precision in various industries.

What Are Engineering Rotary Cutting Teeth?

Engineering rotary cutting teeth are tools that rotate to remove material from a workpiece. They are typically used in machines like rotary cutters, milling machines, and lathes to perform tasks such as cutting, drilling, shaping, and finishing. The cutting teeth are designed to shear or break off small portions of the material, creating smooth and precise surfaces.

These cutting tools are engineered to work with a wide variety of materials, including metals, plastics, wood, and composites. Whether for large-scale manufacturing or precision craftsmanship, engineering rotary cutting teeth play a vital role in shaping and finishing processes.

Types of Engineering Rotary Cutting Teeth

Engineering rotary cutting teeth come in various shapes and sizes, depending on their intended purpose. Here are some of the most common types:

1. Milling Cutters

Milling cutters are a type of rotary cutting teeth used in milling machines. They are designed to remove material by feeding the workpiece into a rotating cutter. Milling cutters are available in different shapes, including flat, slab, ball nose, and end mills, and are used for a variety of cutting operations such as face milling, slotting, and contouring.

These tools are essential for producing high-precision components in industries like aerospace, automotive, and electronics. The sharp cutting teeth on milling cutters allow for efficient material removal and excellent surface finishes.

2. Drill Bits

Drill bits are another form of engineering rotary cutting teeth and are commonly used for drilling holes in a wide range of materials. They are designed to cut through metal, wood, plastic, and concrete. Drill bits come in various sizes and designs, including twist bits, spade bits, and auger bits, each suited to specific drilling tasks.

The cutting teeth of drill bits are engineered to provide optimal performance by maintaining sharpness and durability, ensuring smooth hole creation without damaging the material.

3. Router Bits

Router bits are used in woodwork and carpentry for tasks like shaping edges, making grooves, and cutting intricate designs. These engineering rotary cutting teeth have a high-speed rotation and are designed to cut through wood, laminate, and other soft materials. They come in various shapes, including straight bits, round-over bits, and cove bits.

The sharpness and durability of router bits are essential for achieving clean and accurate cuts on wood and other materials, making them invaluable tools for woodworkers and cabinetry professionals.

4. Grinding Wheels

Grinding wheels are a type of rotary cutting teeth used in grinding machines to remove material through abrasion. These wheels are commonly used for finishing tasks, such as smoothing rough surfaces, sharpening tools, and polishing metals. The cutting teeth on grinding wheels are made from abrasive materials like aluminum oxide or diamond, allowing them to grind away material quickly and efficiently.

Grinding wheels are crucial for achieving fine finishes and maintaining the sharpness of cutting tools in industries such as metalworking, automotive, and tool manufacturing.

5. Saw Blades

Saw blades are widely used as rotary cutting teeth in woodworking and metalworking industries. These tools are designed to cut through various materials, including wood, metal, plastic, and stone. Circular saw blades, band saw blades, and jigsaw blades are all types of engineering rotary cutting teeth that rotate at high speeds to slice through the workpiece.

The teeth on saw blades are designed to maintain sharpness and minimize material waste, ensuring that cuts are clean and precise. Saw blades are essential for cutting large materials quickly and efficiently.

Applications of Engineering Rotary Cutting Teeth

Engineering rotary cutting teeth are employed in a wide range of industries for various tasks. Some of the key applications include:

1. Manufacturing

In the manufacturing industry, engineering rotary cutting teeth are used extensively for shaping, milling, drilling, and finishing parts. They are used to produce everything from small components to large industrial machinery. The precision of rotary cutting teeth ensures that parts are made to exact specifications, which is critical for the performance and safety of the final product.

2. Automotive Industry

In the automotive industry, engineering rotary cutting teeth are used for machining engine components, transmission parts, and chassis elements. Tools like milling cutters and drill bits are used to create intricate parts with high precision. The accuracy provided by rotary cutting teeth ensures that automotive components fit together seamlessly and perform reliably.

3. Aerospace and Defense

The aerospace industry relies on engineering rotary cutting teeth for manufacturing critical components, such as turbine blades, landing gear parts, and aircraft structures. The high-precision cutting tools used in aerospace applications help produce parts that meet strict tolerances and performance standards, ensuring the safety and reliability of aircraft.

4. Construction and Civil Engineering

Engineering rotary cutting teeth are also used in the construction and civil engineering industries for cutting through materials like concrete, steel, and asphalt. Tools like saw blades, grinding wheels, and rotary drills are essential for tasks like cutting rebar, creating foundations, and shaping materials for structural components.

5. Woodworking

In woodworking, engineering rotary cutting teeth such as router bits and saw blades are used for tasks like cutting, shaping, and finishing wood. These tools are essential for creating intricate designs, making precise cuts, and ensuring the durability of wood-based products.

Key Benefits of Engineering Rotary Cutting Teeth

Precision and Accuracy: The sharp cutting teeth ensure that materials are cut with high precision, reducing the need for rework and improving overall efficiency.

Durability: High-quality engineering rotary cutting teeth are made from durable materials, such as carbide or high-speed steel, ensuring they last longer and withstand wear.

Efficiency: Rotary cutting teeth are designed to remove material quickly, improving the speed of production without sacrificing quality.

Versatility: These tools can be used to cut, shape, drill, and finish a wide variety of materials, making them highly versatile for different industries and applications.

Conclusion: The Essential Role of Engineering Rotary Cutting Teeth

Engineering rotary cutting teeth are indispensable tools in many industries, providing precision and efficiency in material removal and shaping. From milling cutters and drill bits to router bits and grinding wheels, these tools play a vital role in ensuring that projects are completed with accuracy and high-quality results. Whether you’re working in manufacturing, automotive, aerospace, or construction, having the right engineering rotary cutting teeth is essential for achieving superior outcomes in your work.

![Engineering rotary cutting teeth Engineering rotary cutting teeth]()