When it comes to high-performance drilling systems, every component plays a crucial role. Among them, the T51 Guide Tube stands out as a key element ensuring superior alignment, wear resistance, and operational longevity. Whether you are in mining, tunneling, or construction drilling, choosing the right T51 Guide Tube means boosting productivity while minimizing downtime.

If you’re serious about reliability and efficiency, the T51 Guide Tube is the component you can’t overlook.

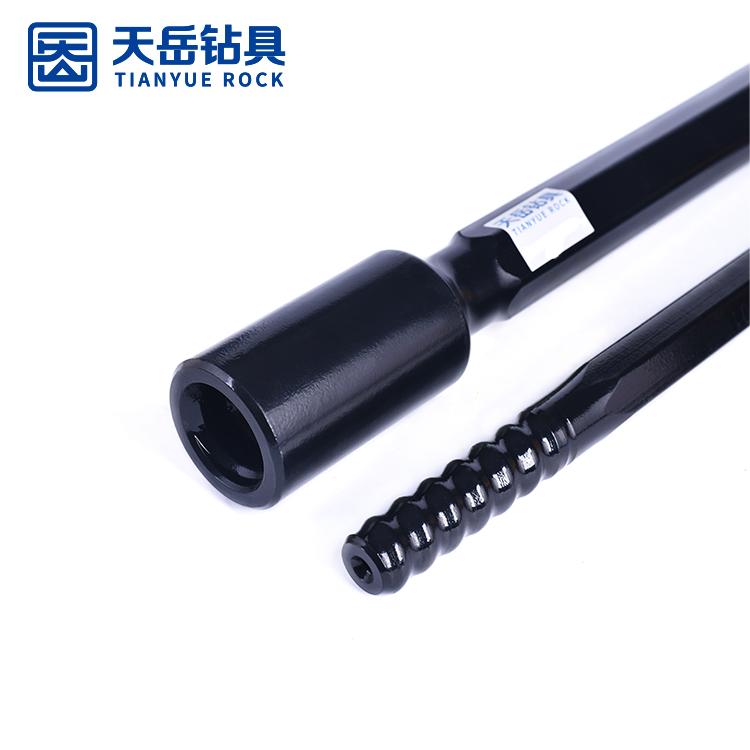

🔧 What is a T51 Guide Tube?

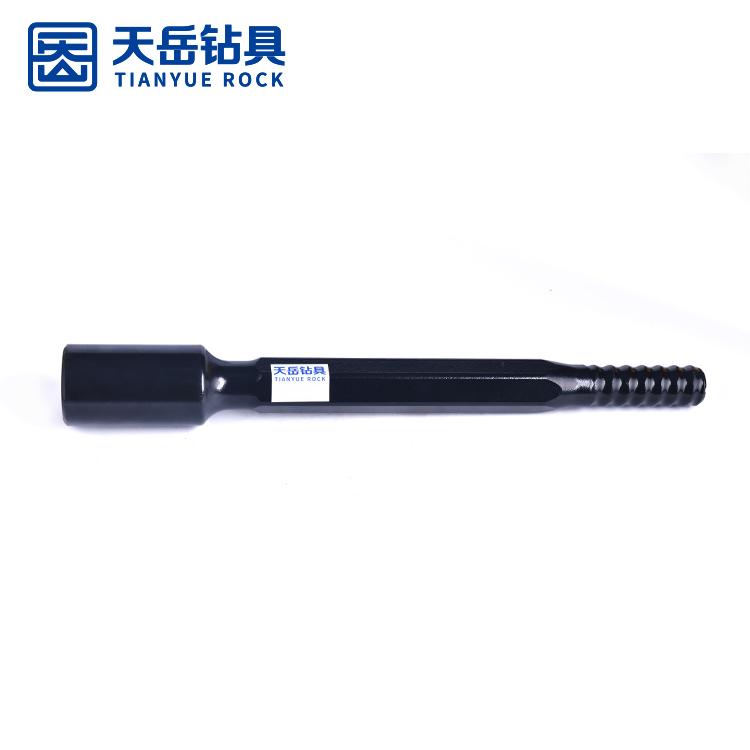

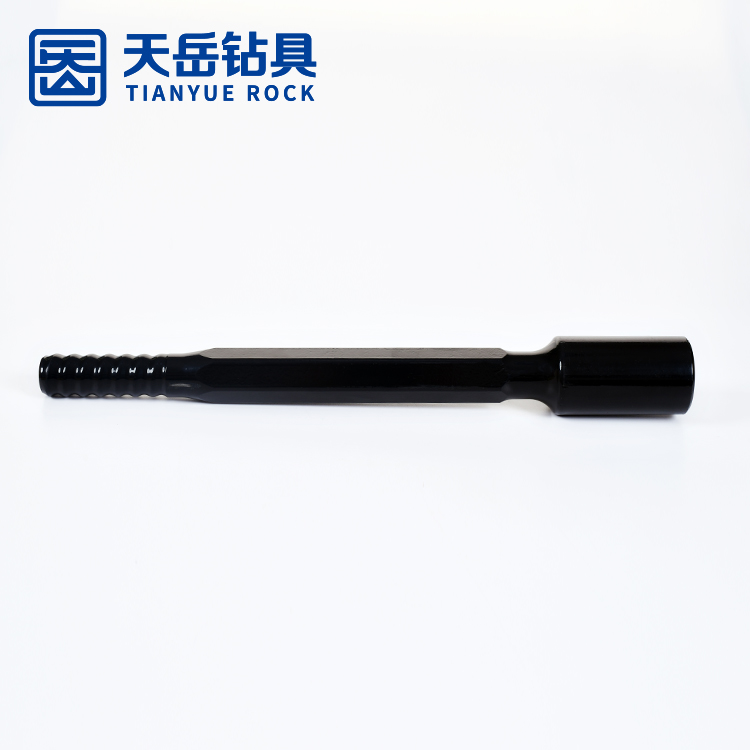

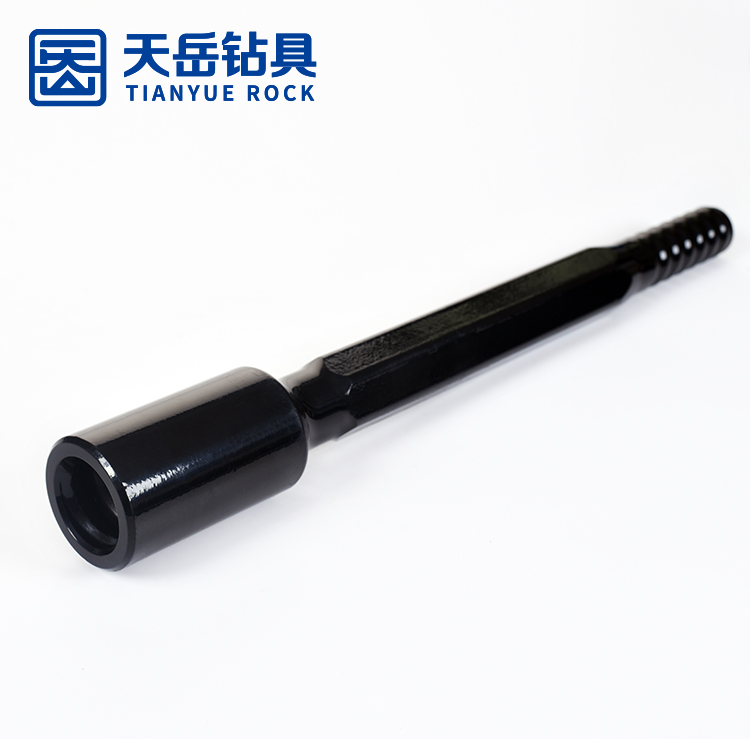

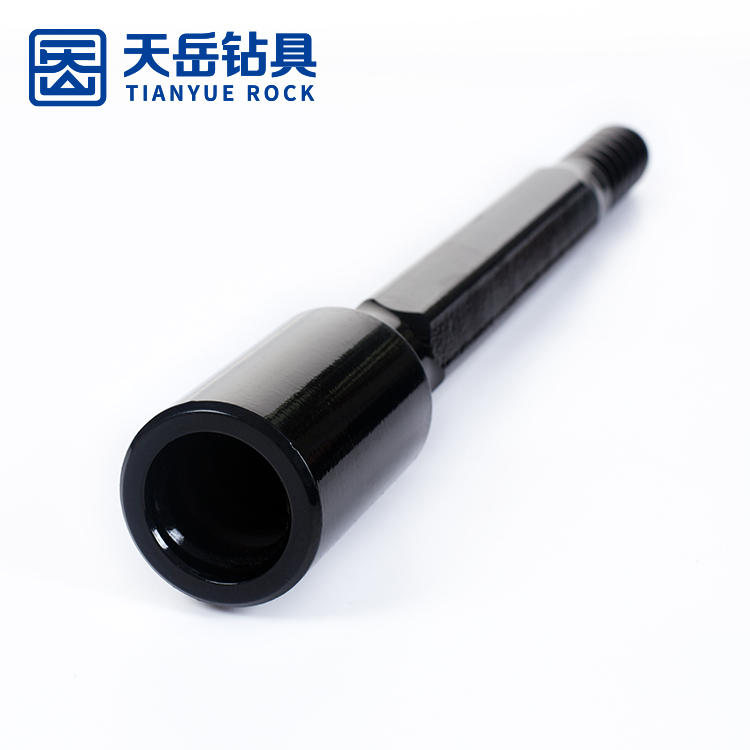

The T51 Guide Tube is a specially engineered steel tube designed for T51 thread systems, typically used in top hammer rock drilling equipment. It serves as a critical guide sleeve that supports the drill rod, aligns impact energy transfer, and protects surrounding components from wear and vibration.

Precision-manufactured and heat-treated for durability, the T51 Guide Tube is essential for ensuring stable and efficient drilling operations—especially in hard rock environments.

🏗️ Why the T51 Guide Tube Matters

The T51 Guide Tube is not just another spare part—it's a performance enabler. Here’s why operators around the globe prefer the T51 Guide Tube for their drilling rigs:

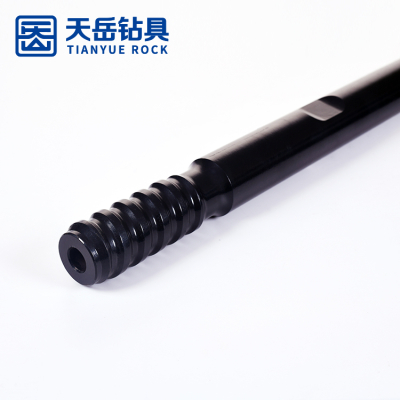

✅ Extreme Wear Resistance: Made from high-grade alloy steel with optimized surface treatments.

✅ Perfect Thread Match: Designed specifically for T51 threaded tools, ensuring tight fit and energy efficiency.

✅ Shock Absorption: Reduces vibration and impact damage to rods and couplings.

✅ Extended Tool Life: Keeps drill string components aligned and working at maximum performance.

✅ Easy Replacement: Designed for quick installation and seamless maintenance in the field.

With the T51 Guide Tube, your drill string stays straight, your energy transfer stays efficient, and your operating cost stays low.

🧪 Technical Specifications of T51 Guide Tube

| Specification | Detail |

|---|

| Thread Type | T51 |

| Outer Diameter | Typically 76mm or per spec |

| Length | 400mm – 1200mm (customizable) |

| Material | Heat-treated alloy steel |

| Surface Hardness | 50–55 HRC |

| Compatibility | T51 drill rods, couplings, shanks |

| Application Sectors | Mining, tunneling, quarrying, geotechnical drilling |

The precision machining of the T51 Guide Tube ensures no wobble or misalignment, even under intense impact loads.

🌍 Where is the T51 Guide Tube Used?

The T51 Guide Tube is used across a wide range of heavy-duty drilling applications:

Open-pit and underground mining

Tunneling and subway projects

Geological core drilling

Hydropower station excavation

Highway and bridge foundation work

No matter the terrain or rock hardness, the T51 Guide Tube delivers exceptional performance and longevity.

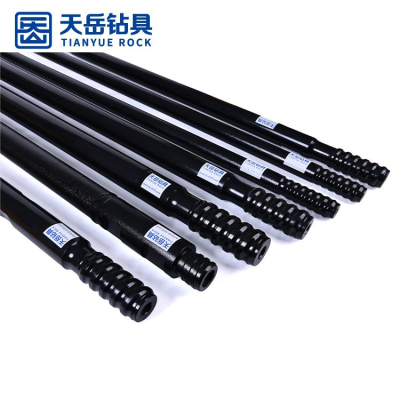

📦 Custom Manufacturing & Global Supply

We offer OEM, ODM, and private-label solutions for clients needing specialized T51 Guide Tube designs. Features include:

Custom diameters and lengths

Optional surface treatments: black oxide, zinc plating

Thread precision CNC-machined to <±0.01mm tolerance

Small MOQ and global delivery within 10–20 days

All T51 Guide Tube batches are subject to strict QC inspection and comply with ISO 9001:2015 manufacturing standards.

💰 Save More, Drill Longer

A low-quality guide tube can lead to:

Misalignment

Equipment wear

Frequent downtimes

Safety hazards

Choosing a premium T51 Guide Tube means extending the life of your drill rods, couplings, and other key components—saving thousands in repair and replacement costs annually.

⭐ Real-World Testimonials

“After switching to the T51 Guide Tube from this supplier, our bit deviation dropped by 30%. Drill rod life also improved by nearly 40%.”

— Operations Manager, Canadian Gold Mine

“High-quality T51 Guide Tubes are hard to find at this price point. These perform just as well as Sandvik equivalents.”

— Purchasing Director, Southeast Asia Drilling Services

🚀 Ready to Upgrade Your T51 Drill System?

If you want higher precision, longer component life, and better ROI from every meter drilled, now’s the time to invest in T51 Guide Tube solutions designed for extreme performance.

📞 Contact our engineering team for tech drawings or a custom quote

🏁 Final Thoughts

In harsh drilling environments, you can’t afford second-rate components. The T51 Guide Tube is trusted by professionals worldwide for its rigid design, precise threading, and proven durability.

Whether you're sourcing for a mine in Chile, a tunnel in Norway, or a foundation project in Southeast Asia—the T51 Guide Tube is your go-to part for maximum performance and minimal downtime.

Invest in reliability. Choose the T51 Guide Tube.