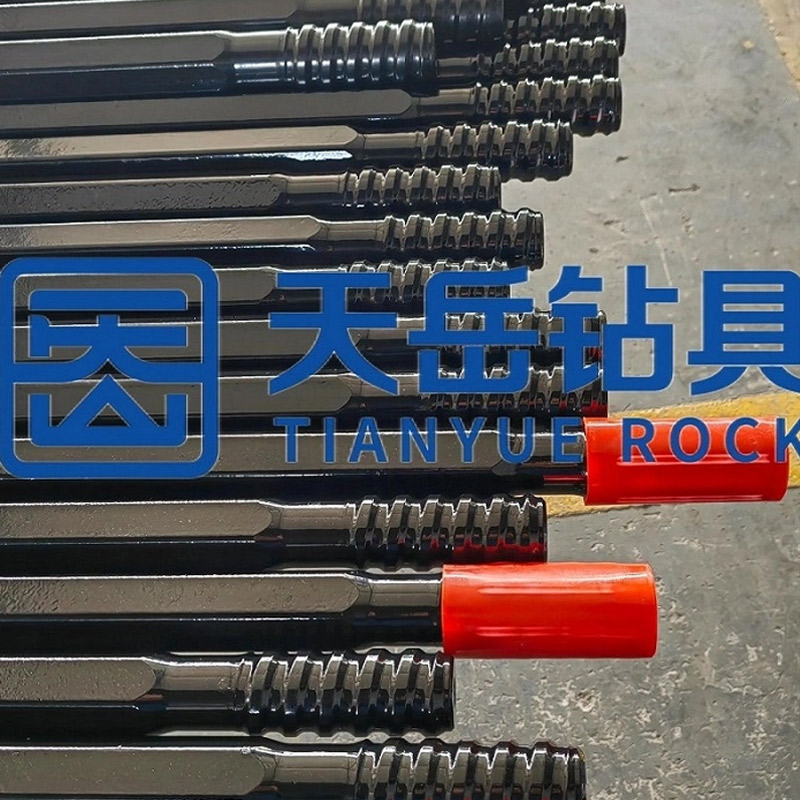

R32 Extension Drill Pipe: Key Features, Applications, and Benefits

R32 Extension Drill Pipe is an essential component in the drilling industry, widely used in applications that require the extension of drill rigs to reach deeper levels of exploration or extraction. Known for its strength, durability, and precision, the R32 extension drill pipe is indispensable in industries such as mining, oil, gas, and construction. This guide will explore the key features, applications, and benefits of R32 extension drill pipe, helping you understand why it's a preferred choice for drilling operations worldwide.

What Is R32 Extension Drill Pipe?

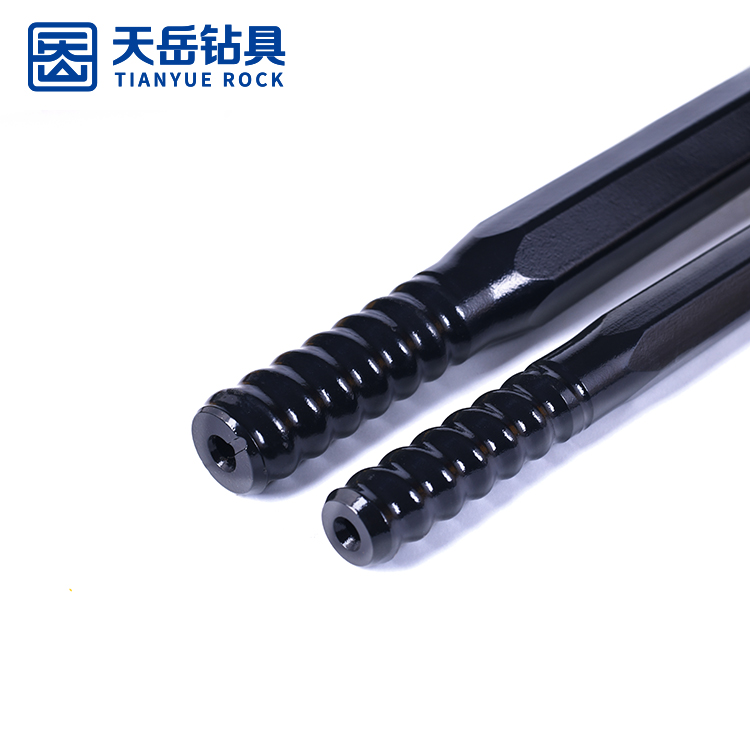

The R32 extension drill pipe is a type of drilling equipment that acts as an extension to the drill string. Typically used in various types of drilling operations, it helps increase the reach of the drill rig, allowing it to penetrate deeper into the earth. The R32 designation refers to the size and threading specifications of the drill pipe, which are crucial for compatibility with other components in the drill string.

Made from high-quality steel, R32 extension drill pipe is engineered to withstand extreme pressures and harsh environments. Its robust construction ensures that it can handle the challenging conditions encountered during deep drilling processes, making it an essential tool for industries that require high-performance drilling equipment.

Key Features of R32 Extension Drill Pipe

The R32 extension drill pipe is designed with several key features that make it ideal for various drilling applications. These features include:

1. Durability and Strength

R32 extension drill pipe is manufactured using high-strength steel materials that ensure maximum durability. These pipes are engineered to resist wear and tear, even in tough drilling conditions. The steel is often heat-treated to enhance its hardness and strength, ensuring it can withstand high impact and pressure while maintaining its structural integrity.

2. Precision Threading

The R32 designation also refers to the specific threading pattern used in the construction of the pipe. Precision threading ensures that the pipe connects seamlessly with other components of the drill string, preventing leaks and ensuring efficient transmission of rotational force during drilling operations. The consistent quality of the threading is vital for the reliability of the overall drilling system.

3. Corrosion Resistance

Drilling operations often take place in harsh environments where exposure to corrosive elements like water, mud, and chemicals is common. R32 extension drill pipe is treated to resist corrosion, significantly extending the lifespan of the pipe and maintaining its performance over time. This corrosion resistance is essential for reducing maintenance costs and ensuring uninterrupted drilling operations.

4. Optimized for Deep Drilling

One of the primary advantages of the R32 extension drill pipe is its ability to extend the reach of the drill rig. With the increasing depth of drilling operations, having an extension pipe like the R32 allows operators to reach deeper layers of rock, mineral deposits, or oil and gas reserves without the need for a completely new rig setup.

Applications of R32 Extension Drill Pipe

The R32 extension drill pipe is used in a wide range of drilling applications. Its versatility makes it suitable for various industries that require deep and precise drilling capabilities.

1. Mining Operations

In mining, R32 extension drill pipe is often used for exploration drilling, where it helps identify the presence of valuable minerals below the earth’s surface. The extension pipe allows miners to reach deeper deposits, increasing the chances of successful mineral discovery. Its durability and corrosion resistance also ensure that the pipe performs well in tough underground conditions.

2. Oil and Gas Exploration

In the oil and gas industry, R32 extension drill pipe is commonly used for drilling oil and gas wells. The pipe’s ability to extend the reach of the drill rig is crucial in accessing deeper reserves of oil and natural gas. The corrosion-resistant properties of R32 extension drill pipe also make it ideal for the challenging environments found in offshore and onshore drilling operations.

3. Geotechnical Engineering

Geotechnical engineers use R32 extension drill pipe to gather soil samples and conduct subsurface investigations. The pipe allows them to drill deep enough to collect samples from multiple layers of the earth, providing vital information for construction projects. The precision and durability of the R32 extension drill pipe ensure that engineers can obtain accurate data for their assessments.

4. Construction and Foundation Drilling

In foundation drilling for large construction projects, the R32 extension drill pipe is used to create deep, stable foundations. Its long reach and precision help drill holes for piling, anchors, and other support structures that are critical for the stability of the building. The R32 extension drill pipe is essential for ensuring the foundation can withstand the weight and forces of the structure it supports.

Benefits of Using R32 Extension Drill Pipe

The R32 extension drill pipe offers numerous benefits that make it an essential component in drilling operations. These benefits include:

1. Enhanced Drilling Efficiency

By extending the reach of the drill rig, the R32 extension drill pipe enables operators to access deeper materials, reducing the need for additional drilling equipment. This enhances the overall efficiency of the drilling operation and reduces setup times, allowing projects to be completed faster and with fewer resources.

2. Cost Savings

While R32 extension drill pipe may represent an initial investment, its durability and longevity can lead to significant cost savings over time. The resistance to corrosion and wear reduces the frequency of replacement parts and lowers maintenance costs. Additionally, its ability to extend the drill rig's reach eliminates the need for multiple rigs, further reducing expenses.

3. Increased Safety

The R32 extension drill pipe is designed with safety in mind. Its high-quality construction minimizes the risk of failure during operation, reducing the likelihood of accidents or delays. The precision threading and robust design also ensure secure connections, preventing hazardous situations like leaks or broken drill strings.

4. Adaptability to Various Environments

The R32 extension drill pipe is versatile enough to be used in a range of environments, from offshore drilling platforms to remote mining sites. Its resistance to corrosion and extreme temperatures allows it to perform well in various conditions, making it a reliable choice for different industries.

Conclusion: The Essential Role of R32 Extension Drill Pipe

The R32 extension drill pipe is a vital component in modern drilling operations. Its ability to extend the reach of drilling rigs, combined with its durability, precision, and corrosion resistance, makes it a preferred choice for industries such as mining, oil and gas, geotechnical engineering, and construction. By using high-quality R32 extension drill pipe, operators can improve the efficiency, safety, and overall success of their drilling projects.