T51 Reaming Drill Bits: The Ultimate Tool for Precision and Efficiency

When it comes to hard rock drilling and tunnel construction, T51 Reaming Drill Bits are the gold standard. Engineered for performance, durability, and precision, T51 Reaming Drill Bits offer unparalleled drilling efficiency in some of the toughest conditions. Whether you're involved in mining, construction, or quarrying, choosing the right T51 Reaming Drill Bits can make a significant difference in productivity and cost savings.

What Are T51 Reaming Drill Bits?

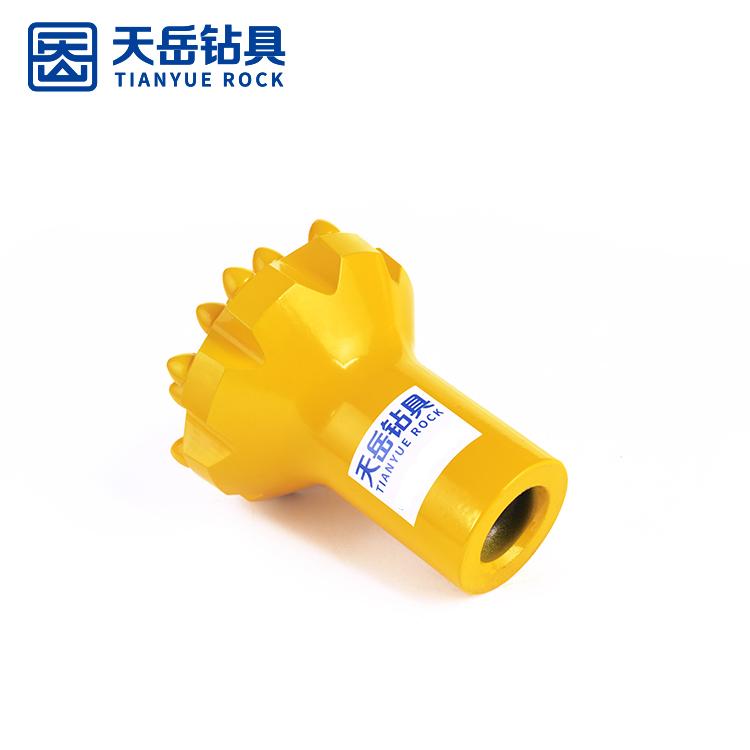

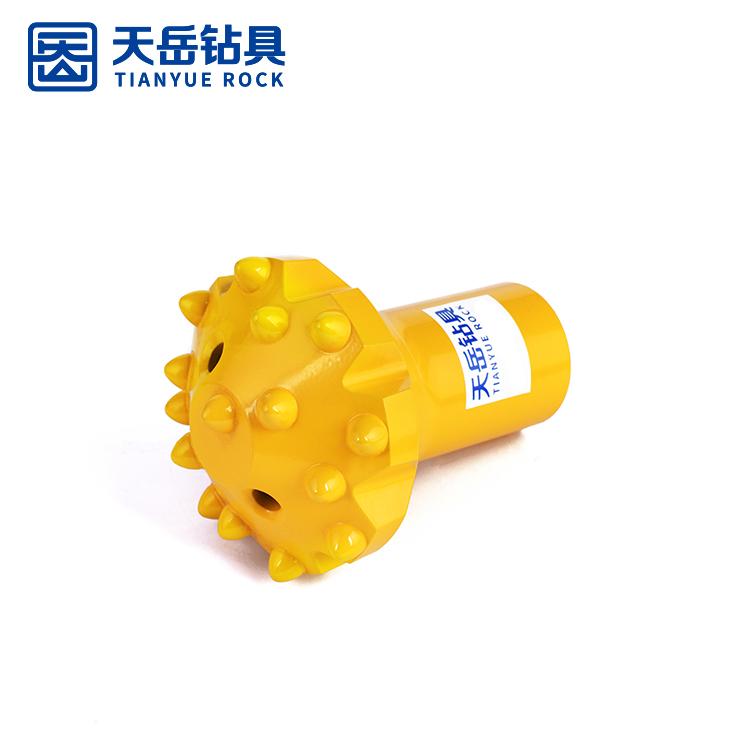

T51 Reaming Drill Bits are heavy-duty drill tools designed specifically for enlarging pilot holes to desired diameters in rock formations. Made from high-quality steel and featuring premium-grade tungsten carbide buttons, T51 Reaming Drill Bits ensure longer service life, consistent performance, and superior penetration rates.

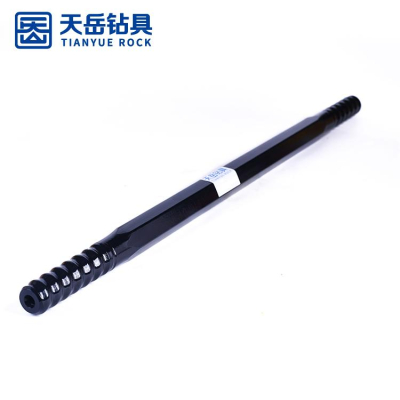

These drill bits are compatible with the T51 thread system, a widely used connection type in top hammer drilling equipment. The robust design of T51 Reaming Drill Bits allows them to handle high-impact forces while maintaining structural integrity during intense operations.

Key Features of T51 Reaming Drill Bits

Choosing T51 Reaming Drill Bits offers several key advantages:

High Wear Resistance: Made with specially treated steel and tough carbide inserts, T51 Reaming Drill Bits withstand abrasive and fractured rock conditions.

Optimized Button Design: The button layout on T51 Reaming Drill Bits is engineered to maximize rock-breaking efficiency and extend service life.

Superior Reaming Performance: T51 Reaming Drill Bits efficiently enlarge pilot holes with minimal deviation, ensuring precision in tunnel boring and mining.

Thread Stability: The T51 connection provides secure and reliable coupling with drill rods, minimizing operational downtime.

Customizable Options: T51 Reaming Drill Bits can be tailored with different face designs and button shapes (spherical, ballistic, or semi-ballistic) based on specific project needs.

Applications of T51 Reaming Drill Bits

T51 Reaming Drill Bits are trusted across a wide range of industries:

Mining Operations: For enlarging blast holes and ventilation shafts.

Tunnel Construction: Essential for creating large, precise boreholes for tunnels and underground passageways.

Hydropower Projects: Used in dam construction and hydroelectric projects requiring deep foundation drilling.

Quarrying: T51 Reaming Drill Bits help produce consistently sized aggregate materials.

Infrastructure Development: Ideal for bridge foundations, metro lines, and underground utilities.

No matter the application, T51 Reaming Drill Bits provide the reliability and efficiency demanded by today's construction and mining professionals.

Why Choose T51 Reaming Drill Bits?

Choosing T51 Reaming Drill Bits brings multiple operational benefits:

Reduced Downtime: Longer tool life means fewer bit changes and higher overall drilling efficiency.

Lower Cost per Meter: High penetration rates combined with durability reduce the overall drilling cost.

Improved Accuracy: Achieve straighter holes with better control, critical for tunneling and structural projects.

Versatile Performance: T51 Reaming Drill Bits perform exceptionally well in various rock conditions, from soft limestone to hard granite.

Investing in high-quality T51 Reaming Drill Bits not only improves project timelines but also enhances the safety and precision of your operations.

How to Select the Right T51 Reaming Drill Bits

To maximize the effectiveness of your T51 Reaming Drill Bits, consider these factors:

Rock Hardness: Select carbide button types and designs suited to the hardness and abrasiveness of the rock.

Hole Size Requirements: Choose the appropriate diameter to match project specifications.

Drilling Equipment Compatibility: Ensure that your hammer and drill rod systems are compatible with the T51 thread connection.

Operational Environment: For extreme temperatures or wet drilling conditions, opt for bits with special coatings or materials.

Consulting with an experienced supplier ensures that you get the best T51 Reaming Drill Bits customized for your unique project needs.

Conclusion: Boost Your Drilling Performance with T51 Reaming Drill Bits

For anyone serious about efficiency, precision, and durability in drilling operations, T51 Reaming Drill Bits are the clear choice. Offering outstanding performance across diverse applications, T51 Reaming Drill Bits have earned their reputation as an indispensable tool in modern mining and construction industries.

Maximize your drilling success — choose T51 Reaming Drill Bits for unmatched quality, reliability, and performance.

![T51 Reaming Drill Bits T51 Reaming Drill Bits]()