Coal Cutter Teeth Sleeves: Essential Components for Efficient Mining Operations

In the world of mining, particularly in coal extraction, coal cutter teeth sleeves play a critical role in ensuring the efficiency and longevity of mining equipment. These sleeves are vital components of coal cutters, which are used to break and cut coal into manageable pieces for further processing. The durability and performance of coal cutter teeth sleeves directly impact the productivity and safety of mining operations.

The high-demand nature of mining, coupled with the need for reliable equipment, makes coal cutter teeth sleeves an essential part of the mining process. They are specifically designed to protect the teeth of the coal cutter, ensuring they stay in optimal condition and can handle the harsh conditions of coal mining.

What Are Coal Cutter Teeth Sleeves?

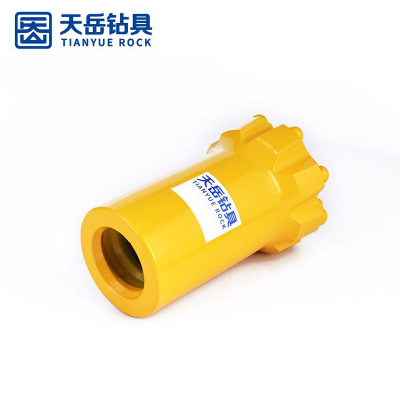

Coal cutter teeth sleeves are protective covers made of durable materials that fit over the cutting teeth of a coal cutter machine. These sleeves are designed to reduce wear and tear on the teeth, extend their lifespan, and improve the overall efficiency of the mining operation. The sleeves act as a shield against the abrasive surfaces encountered during the coal cutting process, preventing damage to the teeth and minimizing downtime.

Made from high-quality steel alloys or other wear-resistant materials, coal cutter teeth sleeves provide a layer of protection that enhances the longevity and performance of the coal cutter teeth. This is essential in environments where the equipment is subjected to constant friction and high-impact conditions.

Benefits of Using Coal Cutter Teeth Sleeves

Using high-quality coal cutter teeth sleeves offers several benefits that contribute to the overall efficiency of coal mining operations:

Increased Durability: By protecting the coal cutter teeth from excessive wear, coal cutter teeth sleeves significantly increase the lifespan of the equipment. This reduces the need for frequent replacements, saving both time and money.

Enhanced Cutting Efficiency: When coal cutter teeth are well-maintained with high-quality sleeves, the cutting process becomes smoother and more efficient, leading to faster and more precise excavation.

Reduced Operational Costs: The use of coal cutter teeth sleeves helps prevent damage to the teeth, reducing maintenance and replacement costs. This allows mining operations to run more cost-effectively.

Improved Safety: By ensuring that the coal cutter teeth remain in good condition, coal cutter teeth sleeves help prevent equipment failure, which can lead to dangerous accidents or delays in mining operations.

Investing in quality coal cutter teeth sleeves can significantly improve the profitability and safety of mining operations.

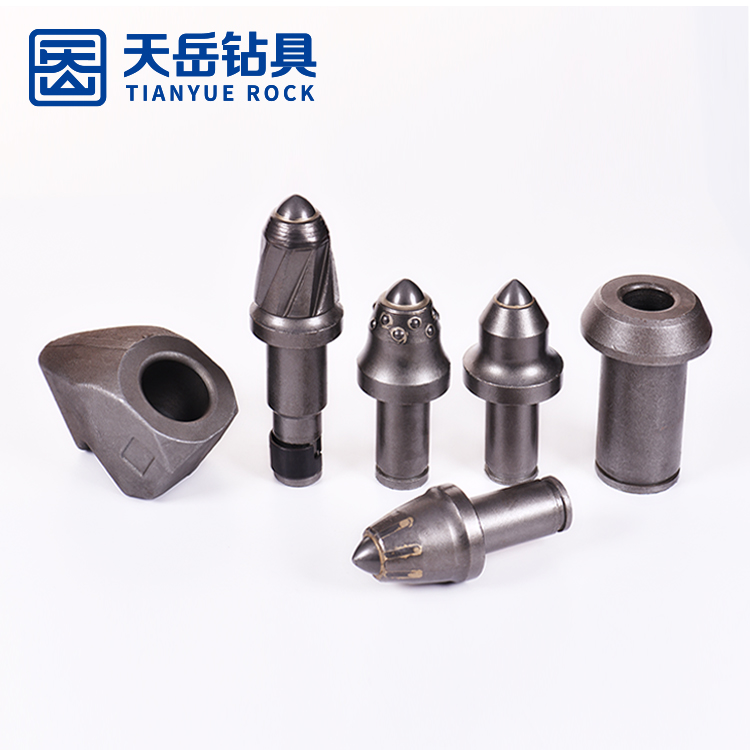

Types of Coal Cutter Teeth Sleeves

There are different types of coal cutter teeth sleeves available, each designed for specific mining conditions and coal types:

Standard Coal Cutter Teeth Sleeves: These are commonly used in general coal mining operations. They provide adequate protection against wear and tear in average coal mining environments.

Heavy-Duty Coal Cutter Teeth Sleeves: Designed for more abrasive or harder coal formations, heavy-duty coal cutter teeth sleeves offer enhanced protection and durability under harsh conditions.

Carbide-Tipped Sleeves: Some coal cutter teeth sleeves feature carbide inserts, which provide exceptional hardness and wear resistance, making them ideal for use in highly abrasive or rocky coal deposits.

Custom Coal Cutter Teeth Sleeves: For specialized mining applications, custom coal cutter teeth sleeves can be designed to meet the specific needs of the operation. These can be tailored in terms of size, shape, and material to optimize performance.

The choice of coal cutter teeth sleeves depends on factors such as the type of coal being mined, the conditions of the mining site, and the specific requirements of the mining operation.

Applications of Coal Cutter Teeth Sleeves

Coal cutter teeth sleeves are used in a variety of mining and coal extraction applications, making them a versatile and indispensable component in the mining industry. Some of the key applications include:

Underground Coal Mining: In underground mining, where space is limited and precision is crucial, coal cutter teeth sleeves ensure that coal cutters operate efficiently without unnecessary downtime.

Open-Pit Coal Mining: In open-pit coal mining operations, coal cutter teeth sleeves provide the protection needed to cut through large volumes of coal quickly and efficiently, ensuring that operations run smoothly.

Coal Processing Plants: After coal is extracted, it often needs to be processed before it can be used. Coal cutter teeth sleeves are used in the initial cutting phase to ensure that the coal is broken into the correct sizes for processing.

No matter the mining application, coal cutter teeth sleeves ensure the continued performance and efficiency of coal cutting equipment, making them an essential component of any mining operation.

Maintenance of Coal Cutter Teeth Sleeves

To get the most out of your coal cutter teeth sleeves, proper maintenance is essential. Here are some maintenance tips to ensure longevity and optimal performance:

Regular Inspections: Inspect coal cutter teeth sleeves regularly for signs of wear and damage. If any sleeve becomes worn or cracked, it should be replaced immediately to prevent further damage to the coal cutter teeth.

Proper Lubrication: Lubricating the sleeves and cutting teeth helps reduce friction, ensuring smoother operation and reducing the chances of premature wear.

Cleaning After Use: After each mining shift, clean coal cutter teeth sleeves to remove coal dust and debris that can cause abrasion and hinder the performance of the equipment.

Timely Replacement: Over time, even the best coal cutter teeth sleeves will wear out. Timely replacement of worn-out sleeves ensures that the cutting teeth remain in good condition, reducing downtime and maintenance costs.

Proper care and maintenance of coal cutter teeth sleeves will keep mining operations running smoothly and efficiently, maximizing productivity.

Conclusion

Coal cutter teeth sleeves are essential components for maintaining the performance, efficiency, and safety of coal cutting equipment. By protecting the cutting teeth from excessive wear, they ensure that coal mining operations can continue smoothly, reduce downtime, and lower operational costs. Choosing the right type of coal cutter teeth sleeves for your mining conditions is crucial to achieving optimal results.

Investing in high-quality coal cutter teeth sleeves will pay off in the long run, offering increased durability, reduced maintenance, and enhanced mining efficiency. Ensure your mining operations stay ahead by using the best coal cutter teeth sleeves available.