Coupling: The Essential Connector in Mechanical Systems

In the world of mechanical engineering and industrial machinery, coupling plays an indispensable role. Acting as a critical connector between two rotating shafts, coupling ensures the efficient transfer of torque, alignment, and motion. Whether in automotive, manufacturing, energy, or aerospace industries, the importance of coupling cannot be overstated. Let's explore how coupling works, its different types, applications, and why choosing the right coupling is crucial for system performance.

What is Coupling?

Coupling is a mechanical device used to connect two shafts together at their ends for the purpose of transmitting power. The primary function of a coupling is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement. In addition to transmitting torque, coupling can accommodate misalignment, absorb shock loads, and protect other components from damage.

In mechanical systems, a properly selected coupling enhances performance, reduces maintenance costs, and extends the operational lifespan of machinery.

Different Types of Coupling

Understanding the types of coupling helps in selecting the best solution for specific applications. Common types of coupling include:

1. Rigid Coupling

Rigid coupling is used when precise shaft alignment is required. It does not tolerate any misalignment and is perfect for applications where alignment can be maintained accurately.

2. Flexible Coupling

Flexible coupling allows for minor shaft misalignments and is ideal for absorbing shocks and vibrations. It provides more versatility compared to rigid coupling.

3. Fluid Coupling

Fluid coupling transmits torque through a fluid medium, providing smooth acceleration and protecting systems against overload.

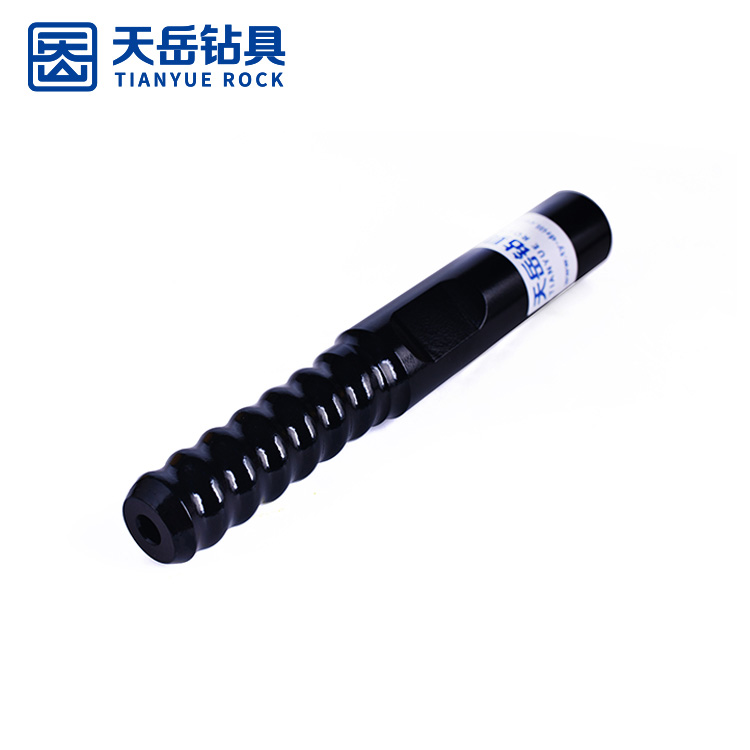

4. Gear Coupling

Gear coupling uses toothed hubs and sleeves to connect shafts, suitable for high-torque and high-speed applications.

5. Disc Coupling

Disc coupling offers high torsional stiffness and can accommodate angular, axial, and parallel misalignments, making it highly reliable in demanding environments.

Each type of coupling serves specific needs based on alignment tolerance, torque capacity, operating environment, and speed requirements.

Key Applications of Coupling

Coupling is vital across various industries, including:

Automotive Industry: Coupling is used in drive shafts, steering systems, and transmission assemblies.

Manufacturing Plants: Heavy-duty machinery relies on coupling for seamless power transfer between motors and machines.

Energy Sector: Wind turbines, pumps, and compressors all utilize different types of coupling for efficient operation.

Aerospace: Precision systems in aircraft depend on lightweight, high-performance coupling for critical operations.

Marine Engineering: Ship propulsion systems use specialized coupling to manage alignment and shock absorption.

In every application, the right choice of coupling significantly affects system performance and reliability.

Why Choosing the Right Coupling Matters

Selecting the correct coupling is essential for achieving optimal system performance. Factors to consider include:

Misalignment Tolerance: Different coupling types accommodate varying levels of shaft misalignment.

Torque Requirements: The torque capacity needed affects the choice of coupling.

Environmental Conditions: Exposure to temperature extremes, moisture, chemicals, or debris can influence coupling material and design.

Maintenance Needs: Some coupling designs require regular maintenance, while others are maintenance-free.

By evaluating these factors carefully, you can ensure that your coupling provides long-lasting, efficient service.

Coupling Innovations and Future Trends

With advancements in materials science and precision manufacturing, coupling designs are becoming more sophisticated. Composite materials, smart sensors embedded in coupling for real-time performance monitoring, and self-aligning technologies are shaping the future of coupling systems.

The next generation of coupling promises improved efficiency, greater durability, and smarter diagnostics, making machinery even more reliable and cost-effective.

Conclusion: The Power of the Right Coupling

In every mechanical system, coupling is a small yet powerful component that holds everything together. By choosing the right coupling, industries can enhance performance, ensure safety, reduce downtime, and protect expensive equipment. Whether you're in automotive manufacturing, energy production, or industrial automation, understanding coupling is the key to engineering excellence.

Unlock the full potential of your systems with the right coupling — where strength, precision, and flexibility meet.