Shank Rods: Essential Components in Drilling and Mining Operations

Shank rods are vital components in the mining, drilling, and construction industries. These robust tools are designed to connect drill bits to drilling machines, ensuring efficient and precise operations in various challenging environments. This article explores the importance of shank rods, their types, applications, and how to choose the right shank rods for your projects.

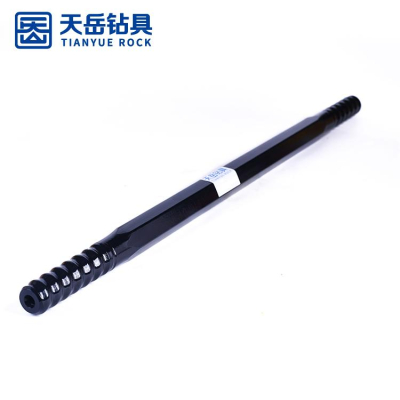

1. What Are Shank Rods?

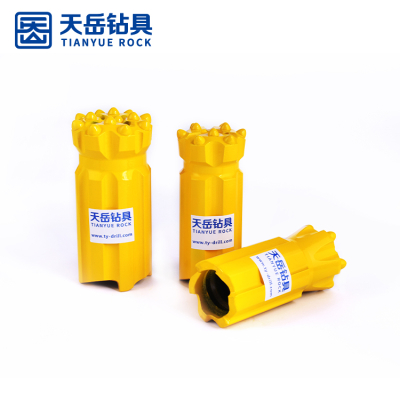

Shank rods are heavy-duty metal rods used primarily in drilling operations. They serve as connectors between the drill bit and the drill machine, enabling the transfer of power and rotational force necessary for drilling into hard surfaces. These rods are designed to withstand extreme pressures and resist wear, making them essential in applications like mining, construction, and geological exploration.

Made from high-strength materials such as steel, shank rods are built to endure the harsh conditions of underground drilling or surface drilling operations. Their durability and ability to maintain structural integrity are crucial for ensuring the success of drilling projects, even in tough terrains.

2. Types of Shank Rods

There are several types of shank rods, each tailored to specific drilling and mining applications. Below are the most common types of shank rods used in various industries:

R Type Shank Rods: These shank rods are typically used in rotary drilling and are designed for high-torque applications. They feature a robust connection that enhances performance and ensures the transmission of force from the machine to the drill bit.

Tapered Shank Rods: Used mainly in mining and construction operations, tapered shank rods feature a tapered connection that allows them to fit securely into the corresponding drill bit or machine. This design improves stability and minimizes the risk of disconnection during use.

Hexagonal Shank Rods: These rods have a hexagonal shape and are often used in applications that require a stable, non-rotating connection. Hexagonal shank rods are particularly useful in applications where precise drilling or repetitive operations are required.

Threaded Shank Rods: Featuring threaded ends, these shank rods are ideal for heavy-duty operations where high torque and power transmission are necessary. The threaded connection ensures a tight, secure fit between the rod and the drill bit.

Non-threaded Shank Rods: Used for light to medium-duty applications, non-threaded shank rods are often used in environments where ease of installation and removal are priorities.

3. Applications of Shank Rods

Shank rods have wide-ranging applications in industries that require drilling or power transmission. Their robustness and versatility make them indispensable in the following areas:

Mining Operations: In the mining industry, shank rods are crucial for drilling through tough rock formations. They connect drill bits to drilling rigs, facilitating the extraction of minerals, coal, and other valuable resources.

Construction and Foundation Drilling: Shank rods are used in foundation drilling to anchor building foundations and in other construction projects that require deep drilling, such as for pylons, bridge supports, or utilities.

Geological Exploration: For geologists, shank rods play a pivotal role in drilling exploration holes to collect soil and rock samples for analysis. This is essential in the search for oil, gas, or mineral deposits.

Water Well Drilling: In water well drilling, shank rods are used to penetrate the earth's surface to access water resources. These rods help maintain a stable drilling environment, ensuring the drill bit remains properly aligned.

Oil and Gas Drilling: In oil and gas exploration, shank rods help connect the drill bit to the rig. They are used in deep drilling projects to extract petroleum or natural gas from beneath the earth’s surface.

4. Benefits of Using High-Quality Shank Rods

Investing in high-quality shank rods offers several advantages that can improve the efficiency and safety of drilling operations. These include:

Durability and Longevity: High-quality shank rods are made from durable materials that can withstand the extreme pressures and wear associated with heavy-duty drilling operations. This reduces the need for frequent replacements and minimizes downtime.

Enhanced Drilling Performance: When shank rods are designed with optimal torque and force transmission capabilities, they enhance the overall performance of drilling machines. This results in faster, more efficient drilling processes.

Improved Safety: Using reliable shank rods minimizes the risk of tool failure, which could lead to accidents or delays in the project. A strong, secure connection between the drill bit and machine reduces the chances of equipment disconnection, ensuring smooth operations.

Cost-Effectiveness: By choosing high-quality shank rods, operators can reduce the frequency of maintenance, downtime, and replacements, leading to cost savings in the long run.

5. How to Choose the Right Shank Rods

Selecting the right shank rods for your operation is crucial for ensuring optimal performance and longevity. Here are key factors to consider when choosing shank rods:

Compatibility: Ensure the shank rods are compatible with your drilling machine and drill bits. Compatibility is essential for maintaining the integrity of the drilling system and achieving efficient performance.

Material Strength: The material used to manufacture the shank rods should be strong enough to handle the stresses and strains of the drilling operation. Steel and alloy materials are often chosen for their resistance to wear and high-strength capabilities.

Application Requirements: Different drilling operations have varying requirements. Choose shank rods based on the specific demands of your project, such as rock hardness, depth of drilling, and machine capabilities.

Size and Length: Shank rods come in different sizes and lengths to suit various drilling machines and applications. Ensure you select the correct size to avoid operational inefficiencies or potential damage to equipment.

6. Conclusion

Shank rods are essential components that play a crucial role in the efficiency and success of drilling and mining operations. Whether used in mining, construction, water well drilling, or oil and gas extraction, these rods help transmit power and enable precise drilling through a variety of materials. Choosing the right type of shank rods based on your specific needs and maintaining them properly ensures long-term success in your drilling operations.