Surface Mining Bits: Essential Tools for Efficient Extraction

Surface mining bits are critical components in the surface mining industry, used primarily to extract minerals and materials from the earth's surface. These specialized tools are designed to endure the extreme conditions of surface mining and offer precision, durability, and efficiency in operations. In this article, we will explore the importance of surface mining bits, their types, and how to choose the right one for your mining operations.

1. What Are Surface Mining Bits?

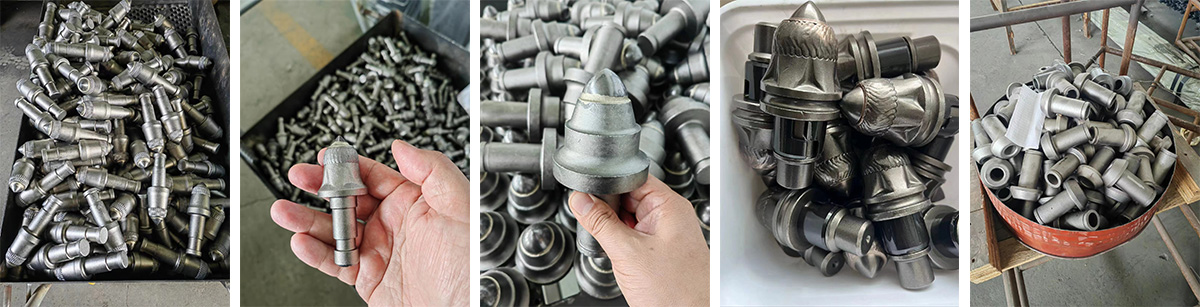

Surface mining bits are specialized drilling tools that are used in surface mining operations to drill into the earth and extract valuable resources such as coal, precious metals, or aggregates. These bits are typically made from high-strength materials such as tungsten carbide or high-grade steel to withstand the harsh environments encountered during mining.

The primary function of surface mining bits is to break through solid rock formations, soft soil, or other materials that make up the earth’s crust. Depending on the rock type and material hardness, the design and structure of the bits vary to optimize drilling efficiency and reduce wear and tear.

2. Types of Surface Mining Bits

The market offers various types of surface mining bits, each suited for specific applications and geological conditions. Understanding the differences between them will help in choosing the most appropriate one for your mining operation.

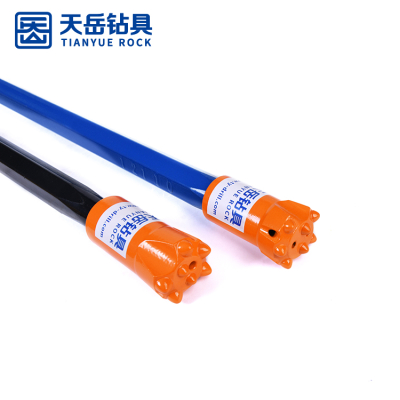

Rotary Drilling Bits: These are commonly used in surface mining operations for their ability to drill through hard rock formations. They utilize rotary motion to break the rock into smaller fragments and are ideal for general-purpose drilling.

Tricone Bits: These versatile surface mining bits feature three rotating cones, each equipped with tungsten carbide inserts or steel teeth. They are widely used in soft to medium-hard formations and are known for their durability and performance in various soil and rock conditions.

PDC Bits (Polycrystalline Diamond Compact Bits): Surface mining bits made with PDC technology are known for their superior cutting ability. These bits are ideal for applications requiring high penetration rates in harder formations. PDC bits are designed to last longer and offer greater efficiency than traditional drill bits.

Down-the-Hole Bits: These surface mining bits are mounted directly on the drill rods and are used in more advanced mining projects. They are particularly effective for drilling deep holes and breaking through tough, compacted materials.

3. Key Factors to Consider When Choosing Surface Mining Bits

Choosing the right surface mining bits is essential for maximizing operational efficiency, reducing costs, and increasing safety in mining projects. Several factors should be considered before selecting a bit for your mining operations:

Rock Formation and Hardness: The hardness and type of rock or material being drilled into play a critical role in determining the type of surface mining bits to use. Softer materials may require less robust bits, while harder materials like granite and basalt demand heavy-duty bits like PDC or tricone bits.

Bit Durability and Wear Resistance: Durability is a key consideration when choosing surface mining bits. Bits that wear out quickly increase downtime and maintenance costs. For long-lasting performance, opt for bits with advanced wear-resistant materials, such as tungsten carbide or PDC inserts.

Penetration Rate: The speed at which a bit can penetrate the material is essential for optimizing productivity. Higher penetration rates are desirable for reducing drilling time and operational costs. Choose bits known for their high-speed drilling capabilities when efficiency is a priority.

Application Type: Different mining operations require specific surface mining bits. For instance, open-pit mining may require different bits compared to underground mining or trenching applications. Ensure that the selected bit matches the operational needs and geological conditions of the site.

4. Benefits of Using High-Quality Surface Mining Bits

Investing in high-quality surface mining bits brings numerous benefits to mining operations, such as:

Increased Efficiency: High-performance bits can significantly improve drilling speed and penetration rates, allowing mining operations to progress faster and more efficiently.

Cost Savings: By reducing wear and tear, high-quality bits last longer, reducing the frequency of replacements and minimizing maintenance costs. This results in overall cost savings for mining companies.

Improved Safety: Reliable and durable bits reduce the likelihood of operational failures and improve the overall safety of mining operations. When bits perform as expected, the risk of accidents and downtime is greatly minimized.

Optimized Performance: By selecting the right surface mining bits for specific conditions, mining operations can achieve optimal performance, ensuring that extraction processes run smoothly and with minimal disruption.

5. Maintenance and Care for Surface Mining Bits

Proper maintenance and care are essential to extending the lifespan of surface mining bits and ensuring they operate at peak efficiency. Here are some tips for maintaining your mining bits:

Regular Inspection: Inspect surface mining bits regularly for signs of wear, damage, or erosion. Early identification of potential issues helps prevent unnecessary downtime.

Clean After Use: Clean the bits after every use to remove debris and prevent material buildup. This helps preserve the integrity of the bit and maintain its effectiveness.

Proper Storage: Store surface mining bits in a dry and clean environment to avoid rust and corrosion. Ensure that bits are protected from moisture and environmental elements when not in use.

6. Conclusion

Surface mining bits are indispensable tools in the mining industry, providing essential drilling capabilities for extracting minerals and resources. Understanding the different types of bits available and choosing the right one for the job can significantly improve mining efficiency, reduce costs, and enhance safety. By considering factors such as rock formation, durability, and penetration rate, mining professionals can select the optimal surface mining bits for their specific needs.

With proper maintenance and care, these high-performance tools can help ensure long-term success in surface mining operations, driving productivity and cost-efficiency across the board.

![Surface Mining Bits Surface Mining Bits]()