T60 Speed Rod: Powering Deeper and Faster Rock Drilling Operations

In the realm of heavy-duty rock drilling, having the right tools is not just a matter of efficiency—it’s essential for safety, cost management, and project success. Among the various rod types available in the market, the T60 Speed Rod has become a go-to solution for deep-hole, high-impact drilling in mining, tunneling, and construction. Known for its strength, stability, and enhanced energy transmission, the T60 Speed Rod is engineered to meet the challenges of extreme drilling environments. In this guide, we’ll explore the design, benefits, and applications of the T60 Speed Rod, explaining why it's a top-tier choice for professionals worldwide.

What Is a T60 Speed Rod?

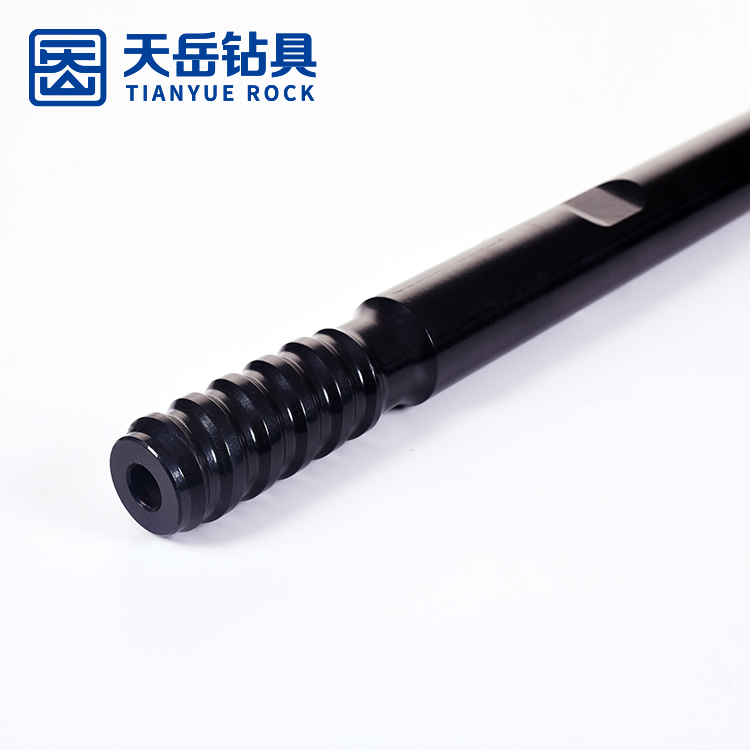

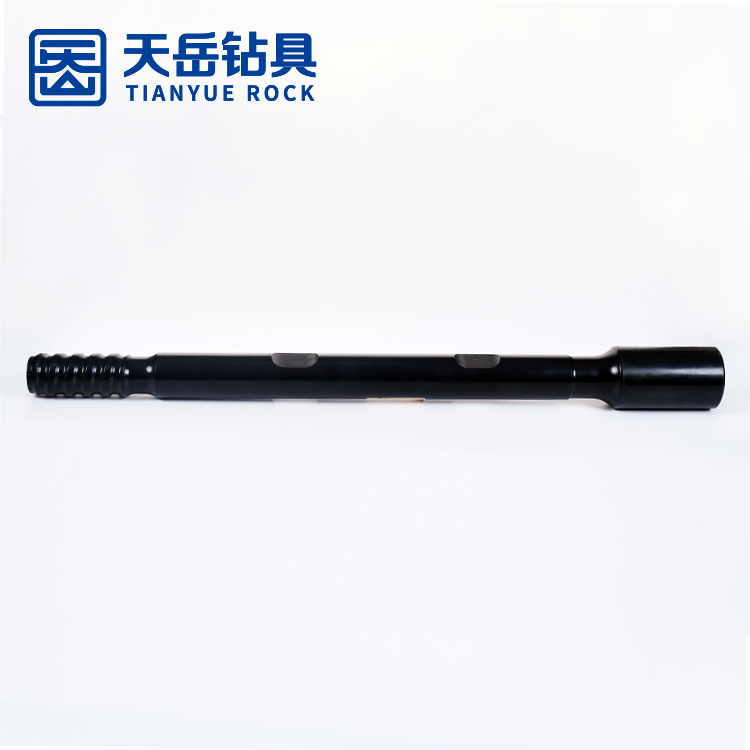

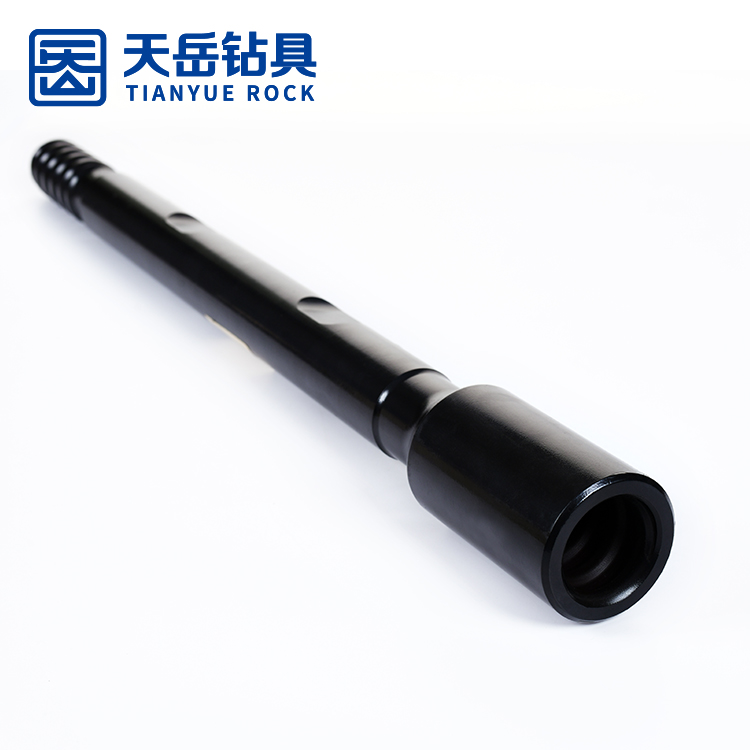

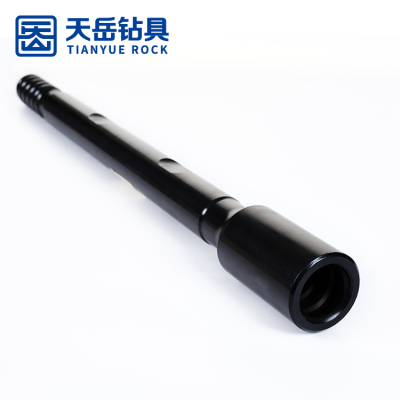

The T60 Speed Rod is a type of extension rod used in top hammer rock drilling. It features a male-male threaded configuration with a T60 thread profile, which is specifically designed for transmitting high-impact energy over long distances. Its large diameter and optimized thread geometry allow for deeper penetration into rock formations while minimizing energy loss and rod deviation.

Speed rods like the T60 Speed Rod are typically used in bench drilling, production drilling in open-pit mines, and tunneling projects where accuracy and speed are critical.

Key Features of the T60 Speed Rod

Robust T60 Thread Profile

The thread design of the T60 Speed Rod provides superior connection strength, minimizing thread wear and loosening under high torque and impact.

Precision-Machined Steel Body

Made from premium alloy steel, the T60 Speed Rod offers high tensile strength and excellent fatigue resistance, even under extreme drilling loads.

Optimized Energy Transfer

Its straight-hole drilling capacity and low resistance allow the T60 Speed Rod to efficiently transmit percussion energy from the rock drill to the bit.

Enhanced Straightness and Rigidity

The rod is carefully heat-treated and straightened to ensure minimal deviation during deep drilling, maintaining borehole accuracy and reducing risk of jamming.

Long Service Life

With improved wear resistance at the thread ends and body, the T60 Speed Rod delivers consistent performance over extended periods, reducing downtime and tool costs.

Advantages of Using the T60 Speed Rod

High Impact Tolerance

The T60 Speed Rod is built to withstand powerful impact forces, making it suitable for aggressive drilling in hard rock formations.

Minimized Energy Loss

The robust construction ensures that more energy reaches the drill bit, resulting in faster penetration rates and higher productivity.

Lower Operating Cost

Thanks to its durability and reusability, the T60 Speed Rod reduces the frequency of replacements and maintenance, optimizing project budgets.

Time-Saving Performance

The rod’s precision-threaded ends allow for quick assembly and disassembly, cutting down on operational delays.

Versatile Compatibility

The T60 Speed Rod is compatible with various shank adapters and drill bits, making it suitable for a wide range of drilling equipment and setups.

Applications of the T60 Speed Rod

T60 Speed Rods are widely used in scenarios that demand deep, straight, and efficient drilling performance. Common applications include:

Open-Pit Mining

Ideal for bench drilling and production blasting, the T60 Speed Rod ensures consistent hole quality and depth.

Tunneling Projects

Provides accurate drill paths for rock bolts, anchors, and ventilation passages in hard rock tunneling.

Hydropower and Dam Construction

Suitable for drilling foundation anchors and drainage holes in granite, basalt, and other dense substrates.

Road and Bridge Infrastructure

Used in drilling dowels and reinforcement holes for structural stability in transportation engineering.

Geotechnical Investigation

Offers reliable performance for test drilling and subsurface sampling in difficult geological conditions.

Best Practices for Using T60 Speed Rods

To maximize the performance and lifespan of your T60 Speed Rod, consider the following operational best practices:

Proper Lubrication

Regularly lubricate the threads to prevent galling and facilitate smooth connection and disconnection.

Correct Coupling

Use torque wrenches to ensure secure and precise connection between rods and shank adapters.

Routine Inspection

Check for signs of thread wear, corrosion, or deformation, and replace rods showing significant damage.

Use Matching Tools

Always pair your T60 Speed Rod with compatible drill bits and shank adapters to ensure energy alignment and prevent damage.

Store in Dry Conditions

Keep rods in a moisture-free environment to avoid rusting and degradation of steel properties.

Why Choose T60 Speed Rods?

The T60 Speed Rod offers unmatched stability, speed, and precision for professional drilling tasks. It’s designed to thrive in high-impact operations where strength and straightness cannot be compromised. Whether you’re a mining engineer seeking reliable production tools or a contractor working on complex tunneling operations, investing in T60 Speed Rods ensures superior outcomes with minimal disruptions.

Final Thoughts

When it comes to deep-hole rock drilling, there’s no room for compromise. The T60 Speed Rod delivers on all fronts—power, precision, and performance. Its engineered thread profile, high-grade steel construction, and excellent energy transmission make it an indispensable asset for any serious drilling operation.

If you aim to boost efficiency, minimize downtime, and enhance borehole accuracy, the T60 Speed Rod is the tool to trust.