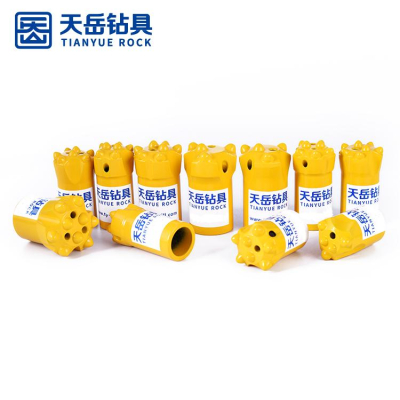

Surface Mining Bits: Essential Tools for Efficient and Precise Excavation

In the world of surface mining, surface mining bits are integral tools that ensure the efficient and accurate excavation of minerals and other valuable materials. Used in various mining applications, surface mining bits are engineered for heavy-duty performance, capable of cutting through tough geological formations and ensuring consistent productivity. Whether you’re working in quarries, open-pit mines, or construction sites, choosing the right surface mining bits is crucial for maintaining operational efficiency and minimizing downtime.

What Are Surface Mining Bits?

Surface mining bits are specialized cutting tools used in surface mining operations to break and excavate rock, soil, and other materials. These bits are typically mounted on rotary drills or drilling rigs and are designed to handle the tough conditions encountered during surface mining activities. Surface mining bits are made from durable materials like high-grade steel and carbide to withstand the intense pressure, heat, and wear experienced during excavation processes.

The primary function of surface mining bits is to cut, crush, and dislodge rock formations, creating the necessary openings for extracting valuable minerals or preparing the area for further processing. By utilizing surface mining bits, mining companies can improve productivity, reduce operational costs, and ensure the safety of workers.

Types of Surface Mining Bits

There are several types of surface mining bits designed for various types of materials and excavation conditions. Each type is tailored to specific mining environments to maximize performance:

Roller Cone Bits: These are widely used in surface mining, featuring rotating cones with tungsten carbide inserts. They are ideal for soft to medium-hard rock and provide excellent penetration rates.

PDC Bits (Polycrystalline Diamond Compact): PDC surface mining bits are designed with synthetic diamond cutters, making them highly effective for cutting through hard rock formations. They are known for their durability and efficiency.

Tricone Bits: A common choice for surface mining, these bits have three rotating cones that provide high efficiency in breaking up tough rock. Tricone surface mining bits are well-suited for a variety of drilling environments.

Drag Bits: These bits are typically used for softer materials and are designed for smoother and more consistent cutting. They are effective for trenching and other surface mining applications.

Diamond Bits: For extremely hard rock, diamond surface mining bits are the best option. With diamond coatings or inserts, they offer unmatched durability and cutting ability.

By selecting the right type of surface mining bits, mining operations can ensure greater efficiency and reduced wear on equipment.

Benefits of Using High-Quality Surface Mining Bits

Choosing high-quality surface mining bits offers several key benefits that directly impact productivity, safety, and cost-efficiency:

Increased Durability: Premium surface mining bits are designed to last longer, reducing the need for frequent replacements and minimizing downtime during mining operations.

Improved Efficiency: High-quality bits increase penetration rates, enabling mining operations to reach target depths more quickly and with less energy consumption.

Cost-Effectiveness: Although high-quality surface mining bits may have a higher upfront cost, they save money over time by reducing maintenance, equipment failure, and replacement expenses.

Enhanced Safety: Durable and reliable surface mining bits ensure a safer working environment by reducing the risk of accidents caused by faulty equipment or unexpected breakdowns.

Investing in quality surface mining bits is essential for optimizing mining operations and maintaining a competitive edge in the industry.

Applications of Surface Mining Bits

Surface mining bits are used in a variety of mining applications, making them versatile tools for different sectors of the mining industry:

Open-Pit Mining: Surface mining bits are ideal for open-pit mining operations, where large-scale excavation is required to access minerals such as gold, copper, and coal.

Quarrying: These bits are commonly used in quarries to extract materials like limestone, granite, and marble, providing high precision and efficiency.

Oil and Gas Exploration: In surface mining for oil and gas drilling, surface mining bits are used to penetrate tough formations and provide access to drilling sites.

Construction: Surface mining bits are essential for preparing construction sites, particularly when heavy excavation is required for infrastructure projects.

Road Construction: These bits are used to break rock and clear land for the construction of roads, highways, and railways.

No matter the industry, surface mining bits provide the strength and precision needed for a wide range of mining and excavation applications.

Maintenance and Care for Surface Mining Bits

Proper maintenance and care for surface mining bits are crucial for extending their lifespan and maintaining optimal performance. Here are some maintenance tips:

Regular Inspections: Check surface mining bits regularly for signs of wear, such as chipped or missing carbide inserts, cracks, or dullness.

Sharpening and Replacing: Some types of surface mining bits, such as roller cone bits, may require sharpening or replacement of worn-out components.

Proper Storage: Store surface mining bits in a dry, safe place to prevent rust and corrosion that can degrade their performance.

Lubrication: Ensure proper lubrication to minimize friction and reduce wear during use.

By following these maintenance guidelines, operators can extend the life of their surface mining bits and maintain a high level of efficiency.

Conclusion

In conclusion, surface mining bits are indispensable tools in the mining industry, providing essential functions for excavation, material extraction, and site preparation. The right surface mining bits ensure efficiency, durability, and safety in challenging environments. By choosing high-quality bits tailored to specific needs, mining operations can enhance productivity, reduce costs, and improve overall performance.

Whether you are involved in open-pit mining, quarrying, or other excavation tasks, the right surface mining bits will help you achieve your goals faster and more efficiently. Don’t compromise on quality—choose the best surface mining bits for your next project.