Excavators:

Excavators are heavy machinery used to remove overburden (the layers of soil, rock, and other materials covering the mineral deposit) in surface mining. They have a bucket attached to a boom, which is used to scoop and transport materials.

Draglines:

Draglines are large machines equipped with a system of ropes and buckets. They are used to remove overburden and expose the mineral deposit. Draglines are commonly used in coal mining operations.

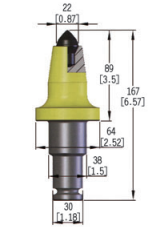

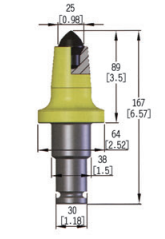

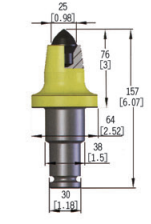

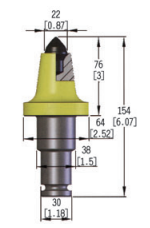

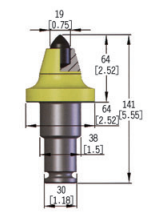

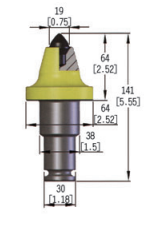

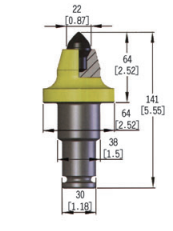

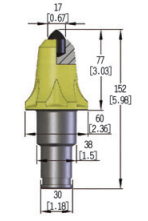

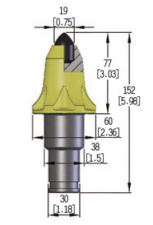

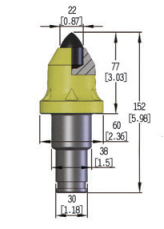

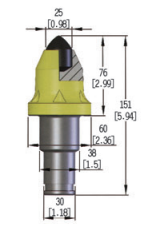

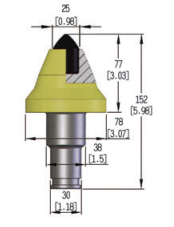

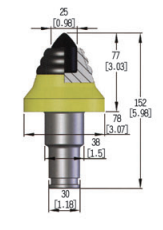

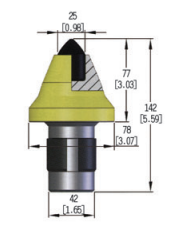

| 38mm/30mm(1.5''/1.18'') step shank |

| JZ89/38-TS6C/M22-23-3 | JZ89/38-TS37C/M25-23-3 | JZ76/38-TS30C/M25-23-3 | JZ76/38-TS32C/M22-23-3 |

![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

|

| JZ64/38-TS5C/Z19-23-3 | JZ64/38-TS40C/M19-23-3 | JZ64/38-TS41C/M22-23-3 |

|

![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

|

|

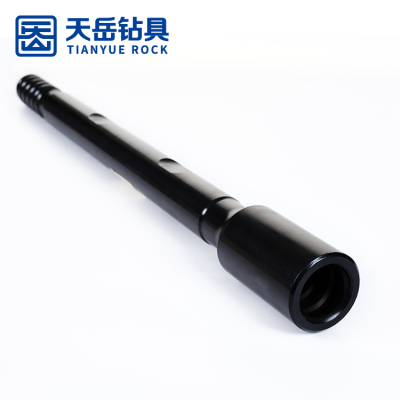

| 30mm(1.18'') WSM step shank |

| JZ77/38-WSM/Z17-23-3 | JZ77/38-WSM/Z19-23-3 | JZ77/38-WSM/Z22-23-3 | JZ77/38-WSM/Z25-23-3 |

![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

|

| JZ77/38-WSMX/Z25-23-3 | JZ77/38-WSMX/Z25-42N-3 |

|

|

![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

|

|

|

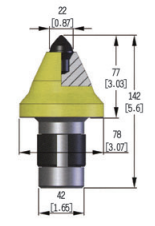

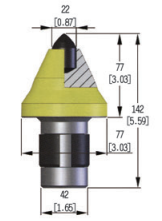

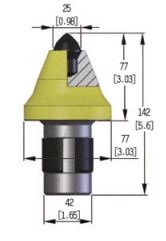

| 42mm(1.66'') WSM step shank |

| JZ77/42-WSM/M22-23-3 | JZ77/42-WSM/Z22-23-3 | JZ77/42-WSM/M25-23-3 | JZ77/42-WSM/Z25-23-3 |

![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

| ![Surface Mining Bits Surface Mining Bits]()

|

In the mining industry, selecting the right surface mining tools is critical for efficient and safe extraction of minerals. Surface mining tools encompass a wide range of heavy-duty equipment and hand tools designed specifically for operations conducted on the earth’s surface, including open-pit mining, quarrying, and strip mining.

This article explores the types, applications, and benefits of various surface mining tools, helping mining professionals optimize productivity and reduce operational costs.

What Are Surface Mining Tools?

Surface mining tools refer to all the equipment, machinery, and implements used in mining activities that take place on or near the earth’s surface. Unlike underground mining, surface mining relies heavily on tools that can handle large volumes of overburden and mineral materials efficiently.

These tools range from massive excavators and bulldozers to specialized cutting and drilling equipment designed for surface extraction.

Common Types of Surface Mining Tools

1. Excavators and Shovels

Excavators and shovels are the backbone of surface mining operations. These surface mining tools are used to dig and load minerals and overburden into trucks or conveyors for transport.

2. Drills and Blasting Tools

Drilling rigs and blasting tools are essential surface mining tools that help break hard rock formations, making mineral extraction easier and faster.

3. Bulldozers and Loaders

Bulldozers and loaders move large quantities of soil and rock, clear debris, and maintain haul roads. These surface mining tools improve site accessibility and operational efficiency.

4. Conveyor Systems

Conveyor belts transport mined materials efficiently over long distances within the mining site, reducing reliance on trucks and lowering fuel costs.

5. Handheld Cutting and Sampling Tools

Handheld picks, hammers, and sampling kits are vital surface mining tools used for detailed geological sampling and minor excavation tasks.

Benefits of Using Advanced Surface Mining Tools

Increased Productivity: Modern surface mining tools allow faster material removal and processing.

Improved Safety: Advanced machinery reduces manual labor and exposure to hazardous conditions.

Cost Efficiency: Efficient tools reduce fuel consumption, maintenance, and operational downtime.

Precision and Control: Cutting-edge surface mining tools offer precise control for blasting and excavation.

Environmental Management: Proper tools minimize environmental disruption through controlled extraction.

Choosing the Right Surface Mining Tools

When selecting surface mining tools, consider the following:

Type and scale of mining operation

Material hardness and geology

Operational budget and maintenance capacity

Safety features and operator comfort

Manufacturer support and after-sales service

Surface Mining Tools Market Trends

The demand for advanced surface mining tools is rising due to increasing mineral exploration and technological innovations. Automation, remote operation, and eco-friendly designs are transforming the surface mining tools landscape, offering greater efficiency and sustainability.

Conclusion

Effective use of the right surface mining tools is key to maximizing output and safety in surface mining operations. Whether it’s large-scale excavators or precise drilling equipment, investing in high-quality surface mining tools will enhance your mining project’s success and profitability.