When precision and durability are non-negotiable in your drilling operations, the T45 Guide Tube emerges as the ultimate solution. Whether you’re drilling in harsh mining environments, performing long-hole blasting, or operating in deep tunneling systems, a reliable T45 Guide Tube ensures your drilling string stays aligned, efficient, and built to last.

Explore why the T45 Guide Tube is the preferred choice of drilling professionals worldwide and how it can drastically improve your productivity and reduce operational costs.

What Is a T45 Guide Tube?

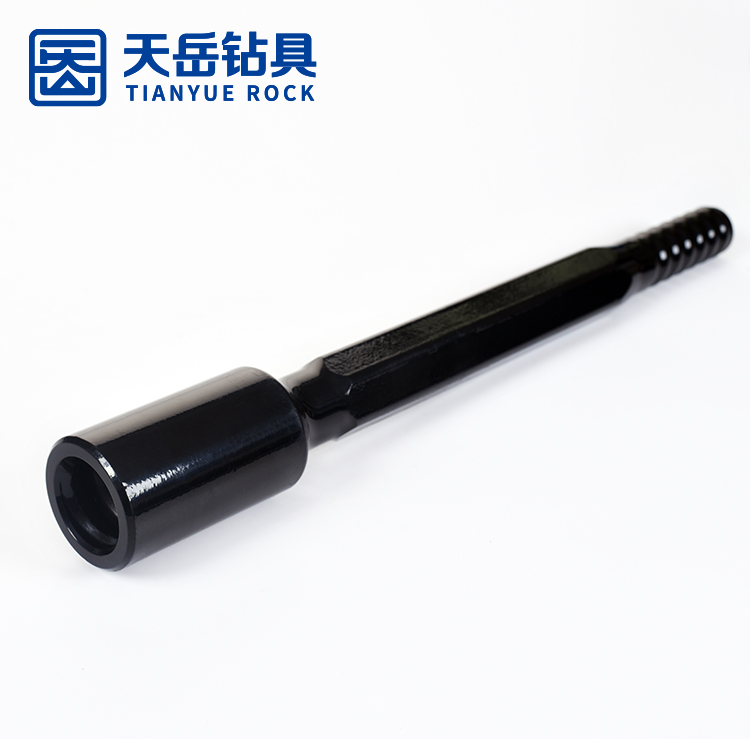

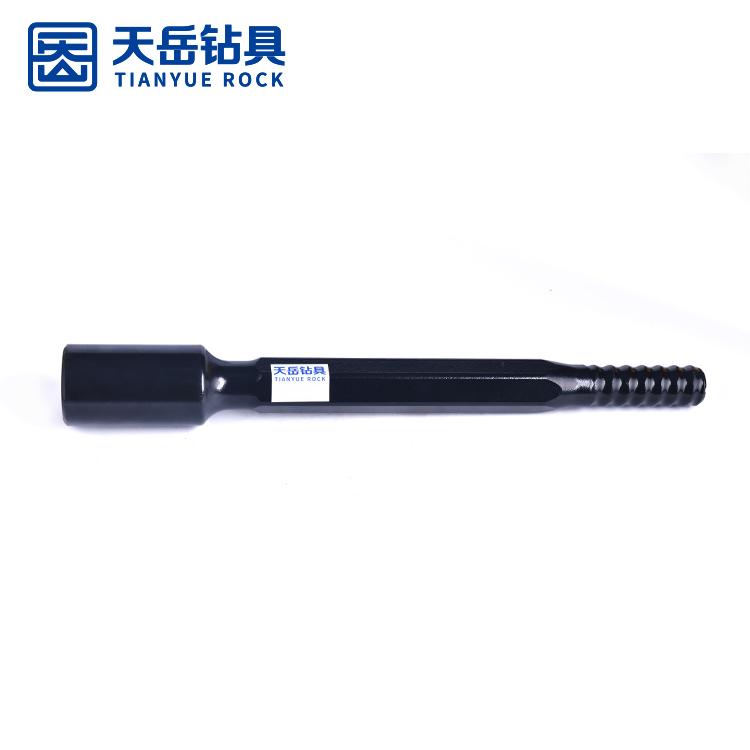

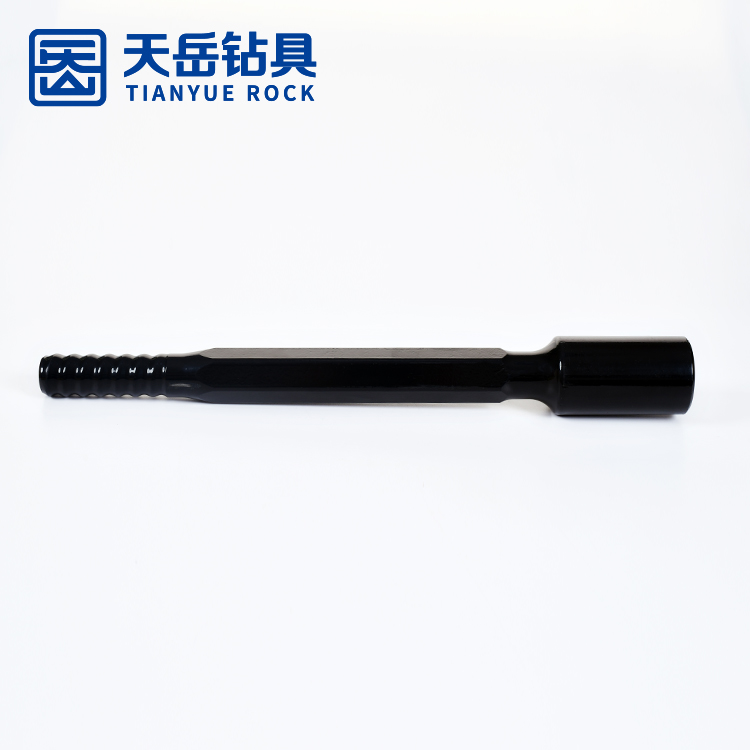

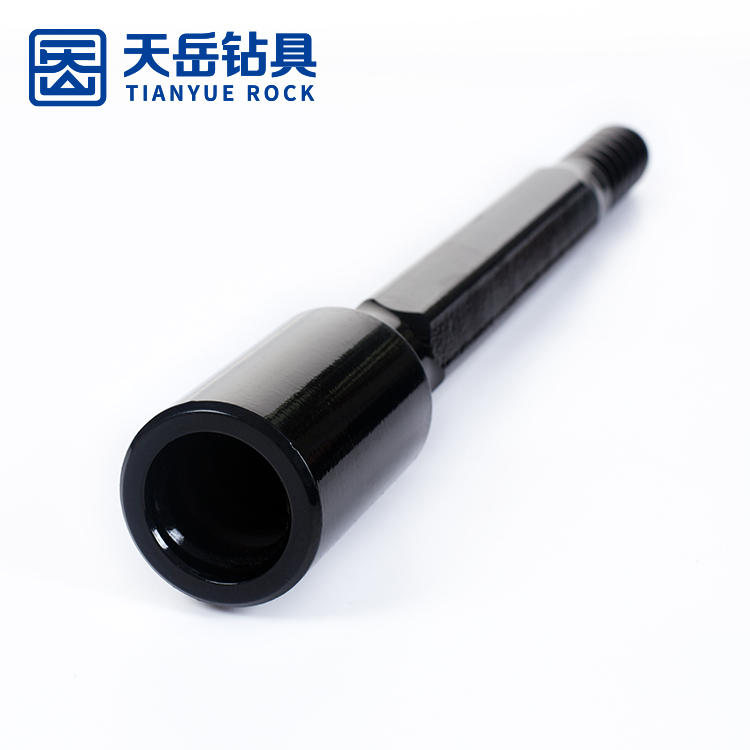

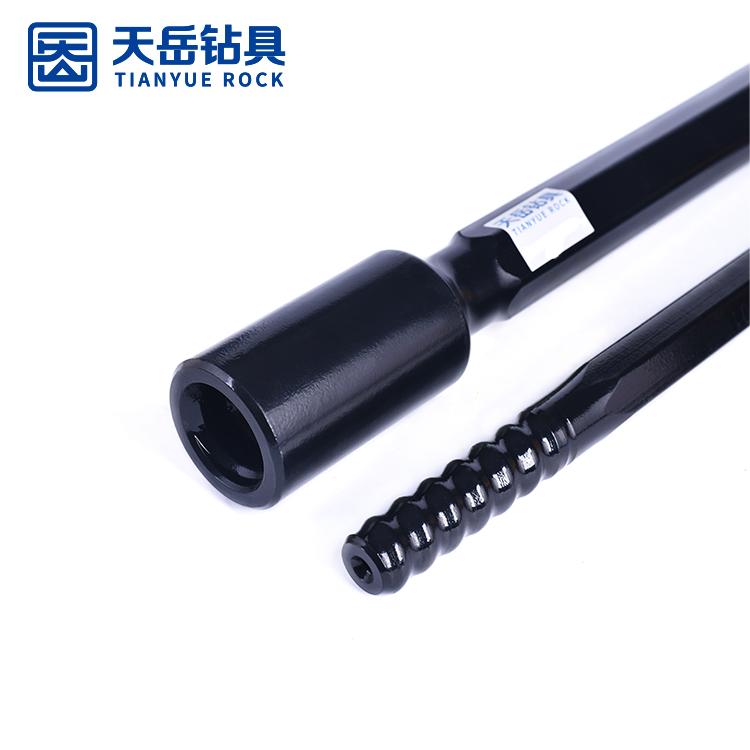

The T45 Guide Tube is a critical component in top hammer drilling systems, serving as a precision connector between the shank adapter and the drill rod. It stabilizes the drill string, absorbs vibrations, and ensures exact hole alignment, especially in deep or deviated boreholes.

With rugged construction and premium materials, the T45 Guide Tube not only increases drilling accuracy but also extends the life of other consumables.

Why Our T45 Guide Tube Is the Smart Choice

Choosing the right T45 Guide Tube can directly impact the performance and ROI of your drilling system. Here’s why clients around the world trust our solution:

✅ Premium Alloy Steel Material

Manufactured with heat-treated, wear-resistant alloy steel, our T45 Guide Tube stands up to extreme mechanical stress and challenging geological conditions.

✅ Precision Machined Threads

Our advanced CNC machining ensures flawless thread compatibility and perfect torque transfer with T45 drill rods and shank adapters.

✅ Extended Service Life

Thanks to its robust design and anti-corrosion coating, the T45 Guide Tube delivers long-term durability, reducing downtime and replacement costs.

✅ Compatible with All T45 Systems

Universally compatible with T45 rock drilling tools from Sandvik, Atlas Copco, Furukawa, and more.

Product Specifications: T45 Guide Tube

| Parameter | Specification |

|---|

| Material | Heat-treated premium alloy steel |

| Thread Type | T45 male/female |

| Length | 400mm, 600mm, 800mm (customizable) |

| Surface Treatment | Black oxide / Zinc plating |

| Weight | 4–8 kg depending on length |

| Application | Bench drilling, tunneling, mining |

All T45 Guide Tubes can be customized according to your technical requirements and project dimensions.

Industries That Rely on T45 Guide Tube

The T45 Guide Tube plays a mission-critical role across multiple sectors:

Mining & Quarrying – Ensures precise hole alignment for safe and efficient blasting.

Tunneling & Underground Construction – Ideal for directional control and minimizing deviation.

Hydroelectric Projects & Foundations – Enhances performance in deep anchoring and exploration drilling.

Key Benefits of Using Our T45 Guide Tube

✔ Improved Drill Accuracy – Keeps holes straight, reducing deviation by up to 40%

✔ Longer Rod Life – Protects joints, reducing wear and tear on expensive drill rods

✔ Reduced Downtime – Minimize breakdowns due to component misalignment

✔ Versatile Application – Performs consistently across hard rock, granite, or sandstone

✔ Increased ROI – Higher productivity with lower maintenance and replacement costs

Client Testimonials

“Switching to this T45 Guide Tube doubled the lifespan of our rods. It’s a game-changer for our drilling crew.”

— Operations Manager, Chile Copper Mine

“Excellent quality. The threads are precise, and performance is far superior to our previous supplier.”

— Project Engineer, Canadian Tunneling Group

T45 Guide Tube: Engineered to Dominate the Depths

Built with strength. Engineered for precision. Optimized for durability.

Our T45 Guide Tube is not just a component — it’s your drilling system’s backbone. With decades of field-proven results and international shipping options, we are ready to support your operation no matter where you are.

📦 Order Your T45 Guide Tube Today

Ready to upgrade your drilling efficiency?

✅ In-stock for immediate delivery

✅ Custom lengths available

✅ Bulk discounts for large orders

Click below to request a quote or speak with our drilling specialist today.