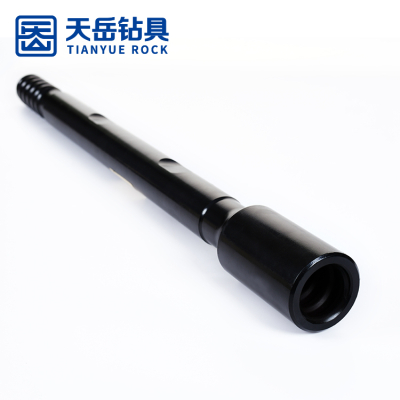

In the world of high-performance rock drilling, every detail matters. Whether you're mining deep underground or working on a demanding infrastructure project, the Shank Adapter HC HBM stands as the vital link between your drifter and drill string—delivering maximum energy transmission, superior durability, and flawless compatibility with HC and HBM drill models.

If you're searching for a rugged, high-precision component that will optimize your drilling operations, the Shank Adapter HC HBM is the perfect solution.

What Is a Shank Adapter HC HBM?

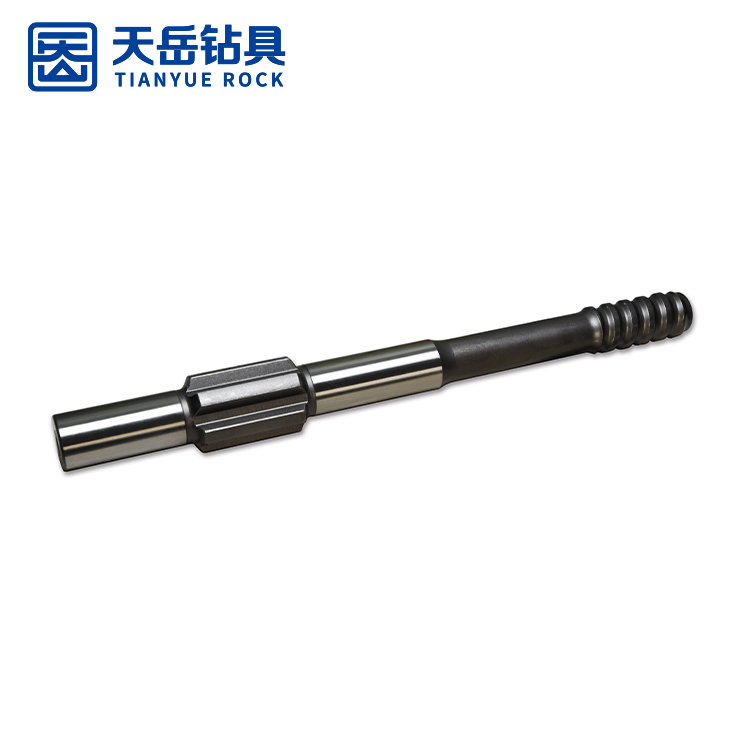

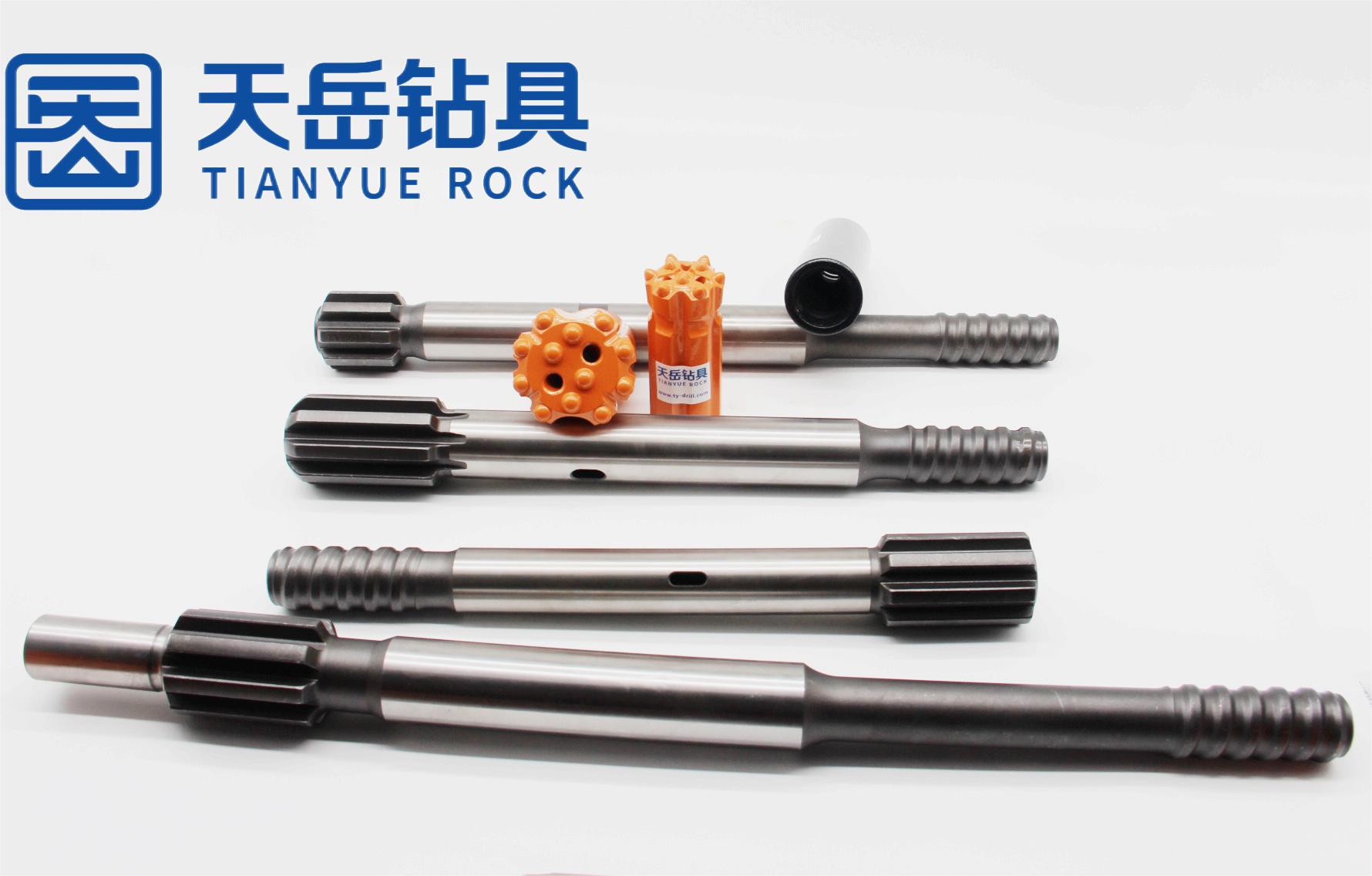

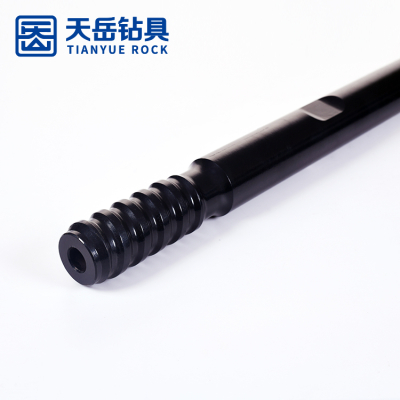

The Shank Adapter HC HBM connects the drifter’s piston to the drill rod, ensuring seamless transfer of impact energy and torque during top hammer drilling. It is specifically engineered for HC (Hydraulic drifters) and HBM (Hydraulic Boom Mounted) drill systems used across underground mining, tunneling, and quarrying applications.

Manufactured from high-grade alloy steel and subjected to advanced heat treatment, this shank adapter offers exceptional resistance to wear, cracking, and fatigue—even in the harshest drilling environments.

Why Choose the Shank Adapter HC HBM?

Unmatched Strength & Reliability

The Shank Adapter HC HBM is built for extreme conditions. Its high-impact resistance and anti-fatigue properties make it ideal for high-frequency drilling operations.

Precision Machining for Maximum Energy Transfer

With tight dimensional tolerances and perfect thread alignment, this adapter minimizes vibration and energy loss—resulting in faster drilling speeds and lower operational costs.

Perfect Compatibility with HC & HBM Drifters

Designed to work seamlessly with models like HC95, HC109, and HBM120, the Shank Adapter HC HBM eliminates alignment issues and downtime.

Extended Service Life

Featuring a carburized or induction-hardened surface, this adapter performs longer under stress—reducing tool change frequency and maintenance costs.

Custom Sizes and Threads Available

Whether you need T38, T45, or T51 threading or specific lengths, the Shank Adapter HC HBM can be tailored to fit your unique drilling system.

Where to Use the Shank Adapter HC HBM

Underground Mining (Ore extraction, development headings)

Tunneling & Metro Projects

Hydropower and Civil Engineering

Bench and Production Drilling in Quarries

Slope Stabilization and Anchor Installation

The Shank Adapter HC HBM is trusted by global professionals in challenging environments where reliability is non-negotiable.

Technical Specifications

| Feature | Specification |

|---|

| Product Name | Shank Adapter HC HBM |

| Thread Options | T38 / T45 / T51 |

| Material | 42CrMo, 35CrNiMnMo (Alloy Steel) |

| Hardness | HRC 55–60 (surface); HRC 38–42 (core) |

| Length Range | 300mm – 700mm (custom available) |

| Compatible Drifters | HC95, HC109, HBM120, HBM140 |

| Heat Treatment | Carburizing or Induction Hardening |

| Surface Coating | Black Oxide / Zinc / Anti-corrosion Treatment |

| Certification | ISO 9001 / CE / API / SGS |

Every Shank Adapter HC HBM undergoes ultrasonic testing, torque simulation, and fatigue analysis to ensure top-tier performance under high-stress operations.

Why Our Shank Adapter HC HBM Stands Out

✅ Direct Manufacturer Pricing

✅ OEM Customization Available

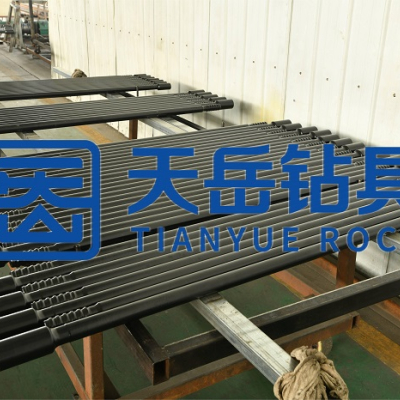

✅ Fast Global Delivery

✅ Bulk Order Discounts

✅ Proven Field Performance in 60+ Countries

We don’t just manufacture tools—we engineer confidence. Our Shank Adapter HC HBM is tested, trusted, and backed by years of hands-on field success.

Order the Shank Adapter HC HBM Today

When failure is not an option, make the smart investment in quality. The Shank Adapter HC HBM ensures optimal tool life, precise energy transfer, and maximum productivity in any drilling condition.

📞 Get a quote today or request a free consultation with our drilling experts. We offer 24/7 customer support, OEM branding, and full logistics assistance.

Final Thoughts

Choosing the right adapter isn’t just about fit—it’s about performance, reliability, and safety. The Shank Adapter HC HBM empowers your entire drilling operation, delivering unmatched strength and long-term efficiency.

Boost your bottom line. Eliminate costly downtime. Equip your rig with the Shank Adapter HC HBM.