12 Degree Tapered Drill Rod: Features, Benefits, and Applications

The 12 Degree Tapered Drill Rod is a crucial component in the drilling industry, offering exceptional performance and reliability for various drilling applications. This rod is specially designed with a 12-degree taper angle, enhancing its ability to handle tough and demanding drilling environments. Whether for mining, construction, or geotechnical drilling, the 12 Degree Tapered Drill Rod provides the strength, durability, and precision needed for successful operations. In this article, we will explore the features, benefits, and diverse applications of the 12 Degree Tapered Drill Rod.

What is a 12 Degree Tapered Drill Rod?

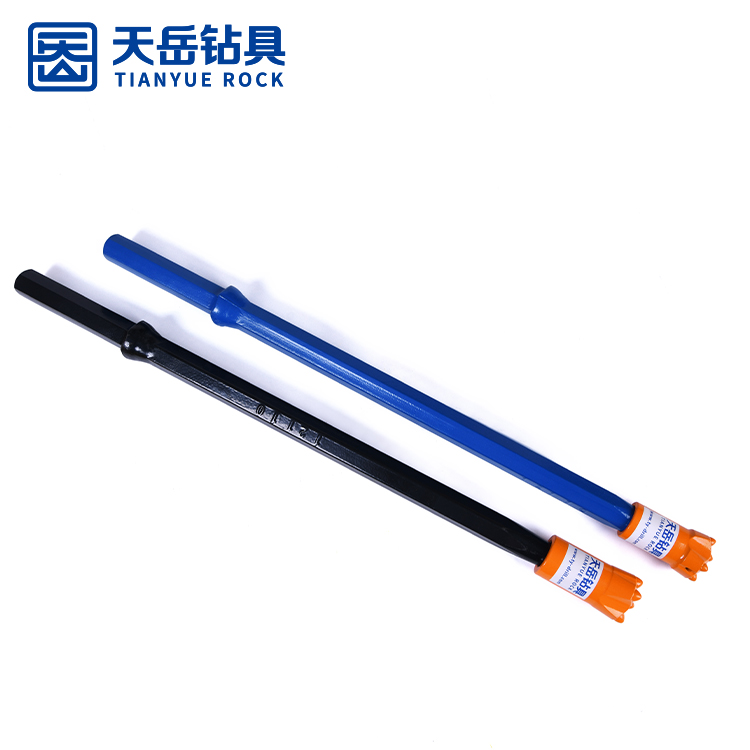

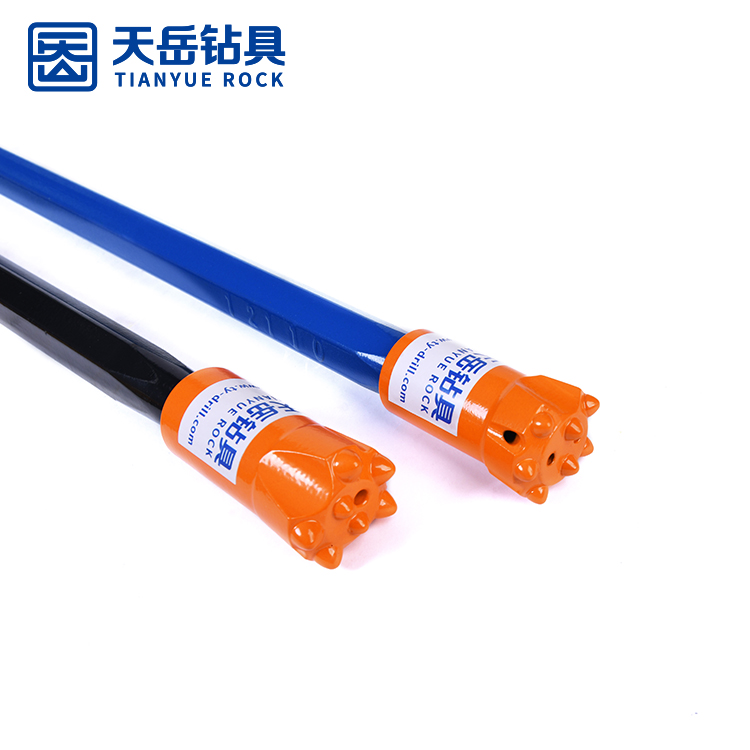

A 12 Degree Tapered Drill Rod is a type of drill rod characterized by its unique taper angle. The 12-degree taper allows for smooth connection and disconnection between drill rods, improving the efficiency and reliability of drilling operations. This drill rod is commonly used in percussion and rotary drilling methods and is often paired with tapered drill bits to ensure optimal performance in a wide range of geological conditions. The 12 Degree Tapered Drill Rod is made from high-quality steel, which provides resistance to wear, corrosion, and fatigue, ensuring long-lasting durability.

Key Features of the 12 Degree Tapered Drill Rod

The 12 Degree Tapered Drill Rod is designed with several key features that make it an essential tool for efficient drilling operations. Below are some of its standout features:

1. 12-Degree Taper Angle

The most notable feature of the 12 Degree Tapered Drill Rod is its 12-degree taper angle. This specific angle allows for easier and more secure connections between drill rods, reducing the likelihood of jamming or misalignment. The tapered design ensures a tight, reliable fit, which minimizes the risk of accidents or equipment failures during drilling operations. The 12-degree taper also aids in faster and smoother operations, as the rods can be quickly and securely connected.

2. Durable Construction

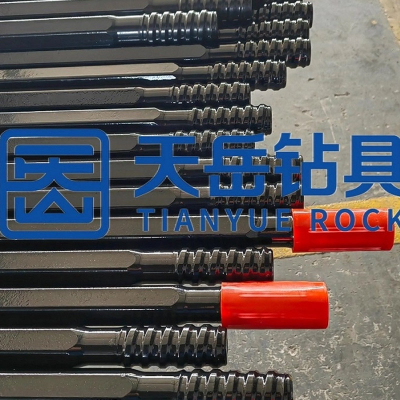

The 12 Degree Tapered Drill Rod is manufactured from high-strength steel alloys, ensuring superior durability even in challenging drilling conditions. These rods are designed to withstand high-pressure environments, abrasive materials, and extreme temperatures, making them highly effective for various types of drilling. The durability of the 12 Degree Tapered Drill Rod translates into extended service life, reducing the need for frequent replacements or maintenance.

3. Enhanced Performance

With its optimized design, the 12 Degree Tapered Drill Rod delivers high-performance results. It provides faster drilling speeds and efficient energy transfer from the rig to the drill bit, resulting in quicker penetration rates and reduced overall drilling time. Whether used for exploration drilling, water well drilling, or geotechnical investigations, the 12 Degree Tapered Drill Rod ensures precise and consistent performance across a variety of geological conditions.

4. Corrosion and Wear Resistance

The materials used in the 12 Degree Tapered Drill Rod are engineered to resist corrosion and wear, ensuring the rod performs reliably even in harsh environments. The corrosion-resistant properties of the rod help it maintain its structural integrity over time, reducing the likelihood of failure due to material degradation. This resistance to wear ensures that the rod remains functional throughout its operational life, even in abrasive drilling conditions.

5. Versatile Compatibility

The 12 Degree Tapered Drill Rod is compatible with a wide range of drilling rigs and equipment. Its design allows it to be used in conjunction with various drill bits, ensuring versatility in multiple applications. Whether you're drilling in hard rock formations, clay, or loose soil, the 12 Degree Tapered Drill Rod is designed to handle the task efficiently.

Benefits of Using the 12 Degree Tapered Drill Rod

The 12 Degree Tapered Drill Rod offers a wide range of benefits, making it a preferred choice for many drilling professionals. Here are some of the key advantages:

1. Improved Drilling Efficiency

The 12-degree taper design of the drill rod ensures quick and secure connections, reducing the time spent on assembling and disassembling the rods during drilling operations. This results in faster drilling speeds and improved efficiency, allowing professionals to complete their tasks more quickly and effectively. The 12 Degree Tapered Drill Rod helps reduce downtime, improving productivity and ensuring timely project completion.

2. Enhanced Durability and Longevity

The high-quality steel used in the construction of the 12 Degree Tapered Drill Rod ensures long-lasting durability and resistance to wear. This durability translates into fewer maintenance requirements and less frequent need for replacements, saving costs over the long term. The rod’s longevity also ensures that projects are not delayed due to equipment failures, maintaining smooth operations.

3. Cost Savings

By offering superior wear resistance and longer service life, the 12 Degree Tapered Drill Rod reduces the costs associated with replacing worn-out rods and maintaining equipment. Its ability to perform reliably in harsh conditions helps lower the overall cost of drilling operations. Additionally, the faster drilling speeds provided by the rod can help shorten project timelines, leading to further cost savings.

4. Increased Safety

The 12 Degree Tapered Drill Rod is designed with safety in mind. Its secure and precise connections reduce the risk of equipment malfunctions or accidents caused by improperly connected rods. This added reliability ensures that drilling teams can operate with confidence, knowing that their equipment will perform safely and consistently. The rod’s construction is also designed to prevent sudden failures, providing additional safety in challenging environments.

5. Flexibility Across Applications

Whether you are drilling for water wells, conducting geotechnical investigations, or engaged in mining exploration, the 12 Degree Tapered Drill Rod provides the flexibility needed for various applications. Its compatibility with multiple drilling rigs and equipment makes it a versatile choice for professionals working in different sectors. The ability to handle a wide range of geological conditions further enhances the 12 Degree Tapered Drill Rod’s usefulness in diverse drilling environments.

Applications of the 12 Degree Tapered Drill Rod

The 12 Degree Tapered Drill Rod is used in a variety of drilling applications due to its versatile design and high-performance capabilities. Below are some of the key industries and applications where the 12 Degree Tapered Drill Rod excels:

1. Mining and Exploration Drilling

The 12 Degree Tapered Drill Rod is commonly used in mining and exploration drilling, where high penetration rates and reliable performance are essential. It allows for efficient drilling through tough rock formations, making it an ideal tool for discovering new mineral deposits and assessing geological conditions. Whether drilling for precious metals, coal, or other valuable resources, the 12 Degree Tapered Drill Rod plays a crucial role in exploration projects.

2. Water Well Drilling

In the water well drilling industry, the 12 Degree Tapered Drill Rod is used to quickly and efficiently drill through various soil and rock formations to access underground water sources. The rod’s fast penetration rate and reliable performance ensure that water well drilling projects are completed on time and within budget. Its durability and resistance to wear are particularly valuable in challenging drilling environments.

3. Geotechnical Drilling

Geotechnical drilling projects require high-precision tools to assess soil stability and gather samples for further analysis. The 12 Degree Tapered Drill Rod is ideal for these applications, as its tapered design ensures precise connections and secure performance in complex drilling conditions. The rod is used to obtain soil and rock samples for construction and infrastructure projects, as well as to assess ground conditions for environmental studies.

4. Construction Drilling

In construction, the 12 Degree Tapered Drill Rod is used for foundation drilling, site preparation, and other tasks requiring deep drilling. Its ability to drill through a variety of geological materials, coupled with its fast penetration rates, makes it an essential tool for building stable foundations for buildings, bridges, and other structures.

5. Environmental and Geothermal Drilling

Environmental and geothermal drilling projects require precision and reliability in drilling equipment. The 12 Degree Tapered Drill Rod is ideal for these applications, where accurate penetration is crucial to reach underground heat sources or collect environmental samples. Its compatibility with various drilling rigs and versatility in different geological conditions makes it a preferred choice for environmental and geothermal professionals.

Conclusion: Why Choose the 12 Degree Tapered Drill Rod?

The 12 Degree Tapered Drill Rod is an essential tool for professionals in the mining, water well drilling, geotechnical, and construction industries. With its superior durability, fast drilling speeds, and versatility across different applications, it delivers outstanding value and reliability. By choosing the 12 Degree Tapered Drill Rod, you can enhance the efficiency, safety, and cost-effectiveness of your drilling operations, ensuring that your projects are completed on time and within budget.