Conical Pick Size Analysis: Essential for Efficient Mining and Drilling Operations

Conical pick size analysis plays a crucial role in improving the efficiency and performance of drilling and mining operations. Conical picks are specialized tools used in various sectors such as construction, mining, and tunneling to break rock and other hard materials. The analysis of conical pick sizes helps engineers and operators optimize the selection and usage of these tools, ensuring maximum efficiency and minimal wear and tear. This article delves into the importance of conical pick size analysis, the factors influencing size selection, and the impact on operational outcomes.

1. What is Conical Pick Size Analysis?

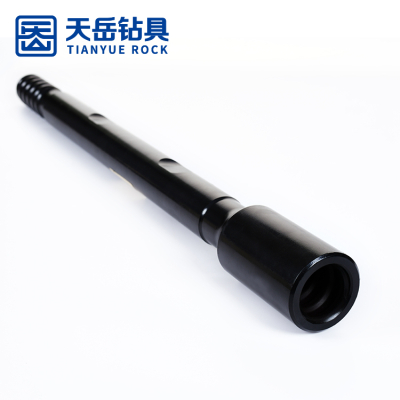

Conical pick size analysis refers to the process of evaluating the optimal size of conical picks used in drilling and mining operations. Conical picks are essential tools that are typically mounted on road headers, continuous miners, or other excavation equipment. These picks have a conical shape that allows them to cut and break through hard materials such as rock, coal, or concrete efficiently.

The size of the conical pick determines its cutting efficiency, durability, and suitability for specific geological conditions. By conducting a conical pick size analysis, professionals can select the best picks that offer optimal cutting power, minimal tool wear, and extended service life.

2. Importance of Conical Pick Size Analysis

The significance of conical pick size analysis cannot be overstated. By analyzing the size of the conical picks used in drilling or mining projects, companies can achieve the following benefits:

Improved Cutting Efficiency: Selecting the right conical pick size ensures that the tool can efficiently break through hard materials, reducing the time and energy required for drilling or excavation.

Reduced Wear and Tear: Analyzing the size of conical picks helps identify tools that can withstand the stresses and pressures of drilling, minimizing premature wear and enhancing tool longevity.

Cost-Effectiveness: By optimizing conical pick sizes, mining and construction operations can lower maintenance costs and reduce the frequency of pick replacements, thus saving money in the long run.

Enhanced Safety: Properly sized conical picks reduce the likelihood of equipment failure or malfunction during drilling operations, enhancing the safety of the workforce and the environment.

3. Factors Influencing Conical Pick Size Selection

Several factors must be considered during conical pick size analysis to determine the most suitable pick size for a particular operation. These factors include:

Material Hardness: The hardness of the material being drilled or mined is one of the most important factors influencing the size of the conical pick. Harder materials, such as granite or basalt, require larger or more robust picks to penetrate and break the surface efficiently.

Drilling Equipment Compatibility: The size and type of drilling or excavation equipment being used also dictate the appropriate size of the conical pick. For example, larger machines may require larger picks to ensure optimal power transmission and tool performance.

Rock Structure and Fractures: The geological conditions, including the presence of fractures or faults in the rock, will affect the choice of conical pick size. Rocks with natural fractures may be easier to break, allowing for smaller picks, while solid, dense rock may require larger picks for effective cutting.

Cutting Depth: The depth of the cut plays a significant role in conical pick size analysis. Deeper cuts often require picks that are larger and more durable to handle the increased force and pressure associated with deeper drilling operations.

Operational Speed: The desired speed of the drilling or mining operation also affects pick size. Faster operations may require more powerful and larger picks to maintain productivity, while slower, more precise drilling may benefit from smaller picks.

4. Conical Pick Size Analysis Process

The conical pick size analysis process involves several key steps to determine the most appropriate pick size for a given task:

Data Collection: The first step in the analysis is gathering data on the material properties, drilling depth, and equipment specifications. This information provides the basis for selecting the right size of conical pick.

Material Testing: Laboratory tests may be conducted on rock samples to assess hardness, compressive strength, and fracture patterns. These results guide the size selection for the conical picks.

Simulation and Modeling: Advanced modeling techniques and simulations can predict how different conical pick sizes will perform in real-world conditions. These tools help engineers assess pick wear, cutting efficiency, and tool longevity before selecting the final size.

Field Testing: Once potential pick sizes have been identified, field tests are conducted to evaluate the real-world performance of each pick size. These tests measure cutting efficiency, wear rates, and overall tool performance.

Optimization: Based on the results of the field tests, adjustments may be made to optimize the pick size for the specific drilling or mining conditions. This may involve choosing a different pick size, altering operational parameters, or modifying the equipment used.

5. Benefits of Proper Conical Pick Size Selection

Proper conical pick size selection provides several key advantages for drilling and mining operations:

Increased Productivity: Correctly sized conical picks improve cutting speed and efficiency, leading to faster project completion times and higher productivity.

Lower Maintenance Costs: Selecting the right conical pick size reduces wear and tear, which translates into fewer tool replacements and lower maintenance costs.

Longer Tool Life: Optimizing pick size extends the service life of the conical picks, reducing the frequency of tool replacement and contributing to cost savings over time.

Improved Operational Efficiency: Properly sized conical picks ensure that the drilling or mining operation runs smoothly and efficiently, with minimal downtime and optimal power usage.

6. Conclusion

Conical pick size analysis is a critical aspect of drilling and mining operations that directly influences the efficiency, cost-effectiveness, and safety of the process. By carefully considering the factors that affect pick size, such as material hardness, equipment compatibility, and cutting depth, operators can select the most suitable conical picks for their specific needs. This not only improves the overall performance of drilling operations but also extends the lifespan of the tools and reduces operational costs.

Investing time and resources into conical pick size analysis ultimately leads to optimized drilling conditions, reduced maintenance requirements, and increased productivity in challenging mining and construction environments.

![Conical Pick Size Analysis Conical Pick Size Analysis]()