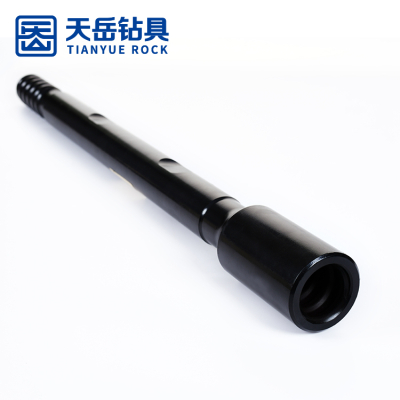

11 Degree Tapered Drill Rod: The Essential Tool for Efficient Drilling Operations

11 Degree Tapered Drill Rod is a vital component in the world of drilling operations, renowned for its efficiency and performance in various industries, including mining, construction, and geotechnical applications. This specialized drill rod, characterized by its 11-degree taper, is designed to provide enhanced control, stability, and durability during drilling tasks, making it a preferred choice for professionals seeking precision and reliability in their equipment.

What is an 11 Degree Tapered Drill Rod?

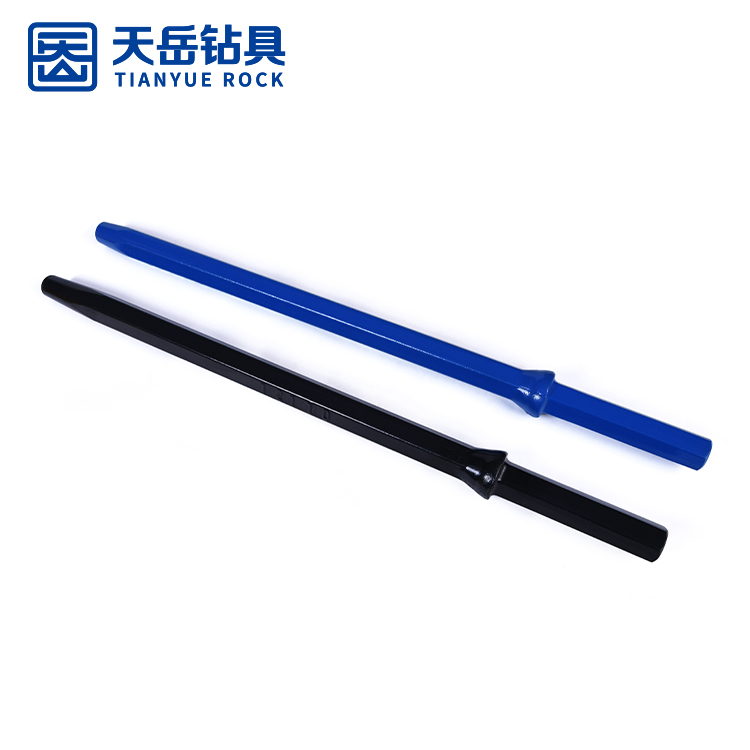

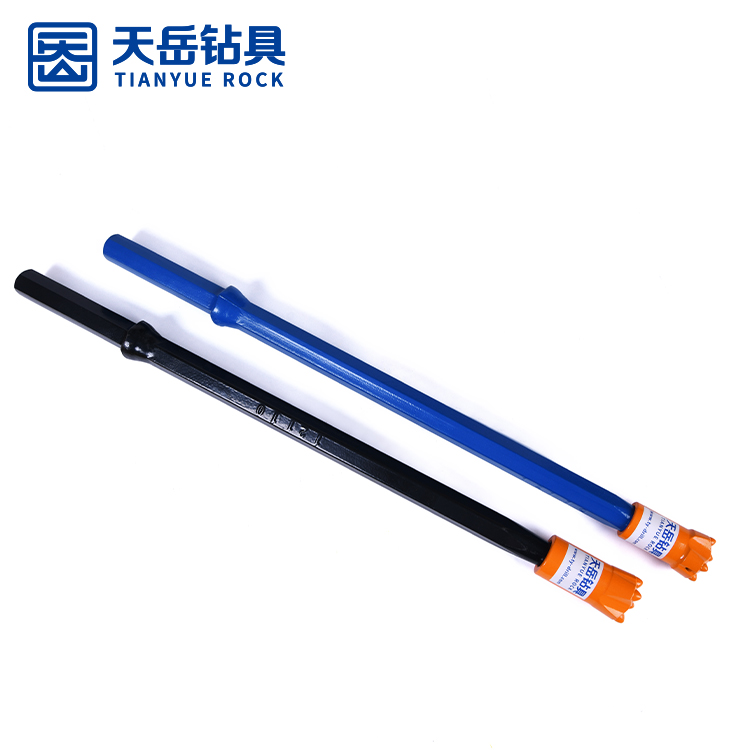

An 11 Degree Tapered Drill Rod is a type of drill rod that has been engineered with a specific taper angle of 11 degrees along its length. This unique taper design plays a crucial role in improving the drill rod’s performance, making it particularly effective in down-the-hole (DTH) drilling and rotary drilling applications. The tapered design allows the drill bit to be more accurately aligned with the borehole, reducing the chances of misalignment and ensuring a smoother, more efficient drilling process.

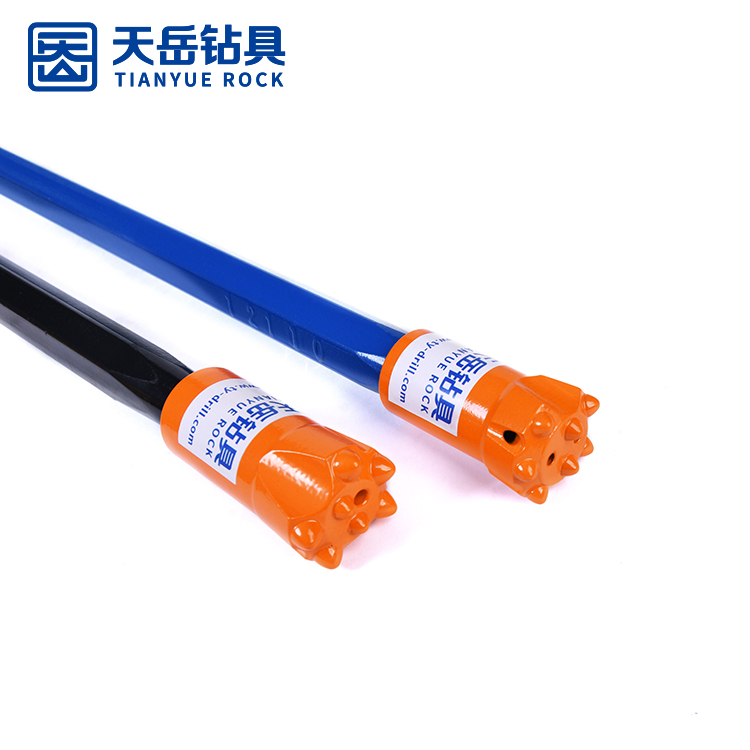

The 11 Degree Tapered Drill Rod is typically made from high-quality alloy steel, providing it with exceptional strength, resistance to wear, and longevity. Its robust construction ensures that it can withstand the extreme conditions often found in drilling operations, such as high-pressure environments, heat, and harsh soil compositions.

Key Features of the 11 Degree Tapered Drill Rod

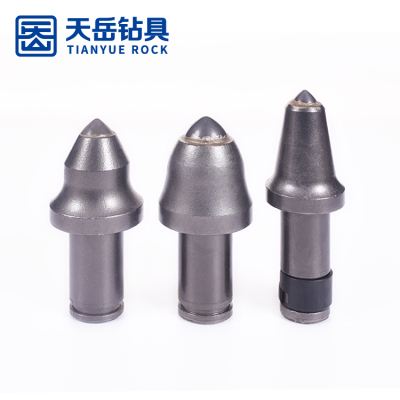

Tapered Design for Enhanced Performance: The primary feature of the 11 Degree Tapered Drill Rod is its tapered shape, which improves the alignment of the drill bit. This results in smoother drilling and more accurate hole formation, which is essential in various drilling applications.

Durability and Strength: Made from high-grade alloy steel, the 11 Degree Tapered Drill Rod is built to endure the harshest drilling conditions. Its high strength allows it to maintain performance over extended periods, even in difficult geological conditions.

Improved Stability: The unique 11-degree taper offers superior stability when drilling at steep angles, reducing the risk of bending or damage to the rod. This feature is particularly beneficial in applications requiring precision and long-term use.

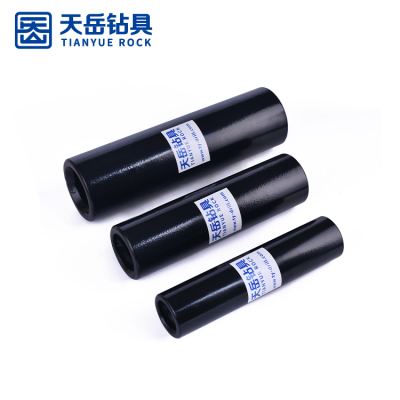

Versatility in Applications: The 11 Degree Tapered Drill Rod is commonly used in various applications, including DTH drilling, water well drilling, geotechnical drilling, and mining operations. Its versatility makes it suitable for a wide range of drilling tasks, both in soft and hard rock formations.

The Importance of the 11 Degree Tapered Angle

The 11-degree taper angle of the 11 Degree Tapered Drill Rod serves several key purposes:

Improved Drill Bit Alignment: The tapered design ensures that the drill bit remains correctly aligned with the borehole, reducing the risk of deviation and improving the overall accuracy of the drilling process.

Smooth Drilling Performance: With its tapered design, the 11 Degree Tapered Drill Rod allows for a more controlled drilling process, leading to fewer complications and a smoother path for the drill bit to follow.

Increased Drilling Efficiency: By ensuring that the drill rod fits snugly into the drill bit, the 11-degree taper allows for more efficient force transfer, reducing energy consumption and speeding up the drilling process.

Applications of the 11 Degree Tapered Drill Rod

The 11 Degree Tapered Drill Rod is used across a range of industries, each benefiting from its superior design and performance:

Mining Operations: In mining, drilling efficiency is key, and the 11 Degree Tapered Drill Rod is essential for reaching deeper deposits with precision. Its ability to drill straight, stable holes makes it ideal for both surface and underground mining applications.

Water Well Drilling: When drilling for water wells, maintaining a steady drilling operation is critical. The 11 Degree Tapered Drill Rod ensures that water well drilling is done quickly and effectively, with minimal risk of misalignment.

Geotechnical Drilling: In geotechnical applications, the 11 Degree Tapered Drill Rod is often used for obtaining soil samples and installing monitoring wells. Its stable and accurate drilling makes it indispensable for these types of projects.

Construction Projects: Construction projects often require drilling for foundations and deep excavation. The 11 Degree Tapered Drill Rod ensures that holes are drilled with minimal deviation, making it ideal for projects that demand precision.

Benefits of Using 11 Degree Tapered Drill Rods

Increased Drilling Accuracy: One of the most significant advantages of using the 11 Degree Tapered Drill Rod is the precision it offers. The rod’s tapered design allows for more accurate alignment, reducing errors during drilling and improving the overall quality of the work.

Enhanced Longevity and Durability: Built from high-quality alloy steel, the 11 Degree Tapered Drill Rod offers exceptional wear resistance, ensuring it remains operational for a long time, even under the toughest conditions.

Cost-Effectiveness: While the initial investment may be higher, the 11 Degree Tapered Drill Rod proves to be cost-effective over time due to its extended lifespan and reduced need for replacements. This makes it a smart choice for long-term drilling operations.

Minimal Maintenance: The robust construction and efficient design of the 11 Degree Tapered Drill Rod lead to reduced wear and tear, requiring less maintenance and contributing to higher operational efficiency.

Choosing the Right 11 Degree Tapered Drill Rod

When selecting an 11 Degree Tapered Drill Rod, it’s important to consider factors such as:

Material Quality: Ensure that the rod is made from high-quality alloy steel to guarantee strength and longevity.

Compatibility with Drill Bits: Make sure the 11 Degree Tapered Drill Rod is compatible with the drill bits and equipment you are using. Proper compatibility ensures efficient operation and minimizes the risk of damage.

Drilling Depth and Application: Consider the depth of your drilling operations and the specific needs of your project. Choose a rod that matches the required drilling capacity and application to maximize performance.

Conclusion

The 11 Degree Tapered Drill Rod is an essential tool in the drilling industry, offering unmatched accuracy, durability, and efficiency. Whether used in mining, water well drilling, or construction, this drill rod ensures optimal performance and minimal maintenance. Its unique taper angle improves alignment, leading to smoother, more controlled drilling operations. For professionals seeking precision and longevity, the 11 Degree Tapered Drill Rod is an invaluable asset in any drilling project.