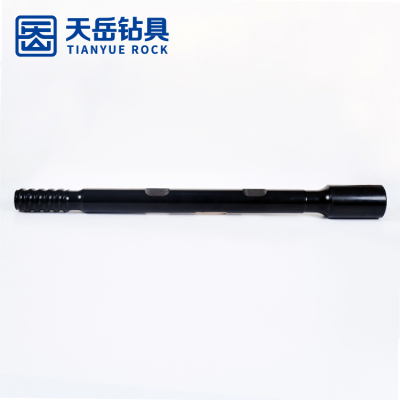

Integral Drill Rods: Essential Tools for Drilling Operations

Integral drill rods, also known as integral drill steels, are crucial components in drilling applications, particularly in mining, construction, and tunneling industries. These high-performance tools are designed to offer durability and reliability during operations that require high drilling speeds and heavy impact.

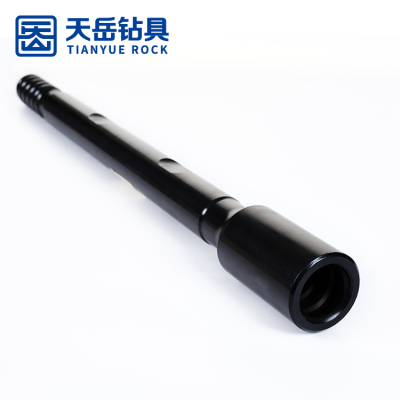

What Are Integral Drill Rods?Integral drill rods are a type of drill rod that is manufactured from a single piece of steel. Unlike conventional threaded rods, integral drill rods are forged or machined as one complete unit, eliminating the need for separate components such as couplings or sleeves. This design offers enhanced strength, reliability, and uniformity.

Applications of Integral Drill RodsIntegral drill rods are widely used in mining, construction, and geological drilling applications. They are particularly beneficial for operations involving heavy-duty drilling, such as those found in hard rock mining or tunnel construction. Their ability to withstand high levels of impact and wear makes them ideal for rotary drilling, percussive drilling, and exploration drilling tasks.

Mining Operations: In hard rock mining, integral drill rods are used to drill holes for blasting, which are essential for fragmenting rock for extraction.

Construction: During the construction of tunnels, roads, and other large infrastructure projects, these drill rods are used for drilling deep holes that accommodate anchors or explosives.

Geological Exploration: Integral drill rods are employed in geological drilling for obtaining core samples and conducting exploratory drilling.

Key Advantages of Integral Drill Rods

Strength and Durability: The one-piece construction provides superior strength, making the rods more resistant to wear, corrosion, and fatigue.

Efficiency: As a seamless unit, integral drill rods eliminate the potential for damage caused by loose components, ensuring uninterrupted drilling operations.

Cost-Effective: Although integral drill rods may have a higher upfront cost, their extended lifespan and enhanced performance reduce maintenance and replacement costs over time.

Choosing the Right Integral Drill RodWhen selecting an integral drill rod for your project, it is important to consider factors such as the rock formation, the depth of the drill, and the drilling conditions. Choosing the correct diameter, material type, and strength rating of the drill rod will ensure optimal performance and safety during operations.

ConclusionIntegral drill rods are essential tools in high-impact drilling applications, offering exceptional strength, efficiency, and reliability. By choosing the right integral drill rod for your project, you ensure smoother operations and longer-lasting performance. Whether you're working in mining, construction, or geological exploration, investing in high-quality integral drill rods is crucial to the success of your drilling projects.