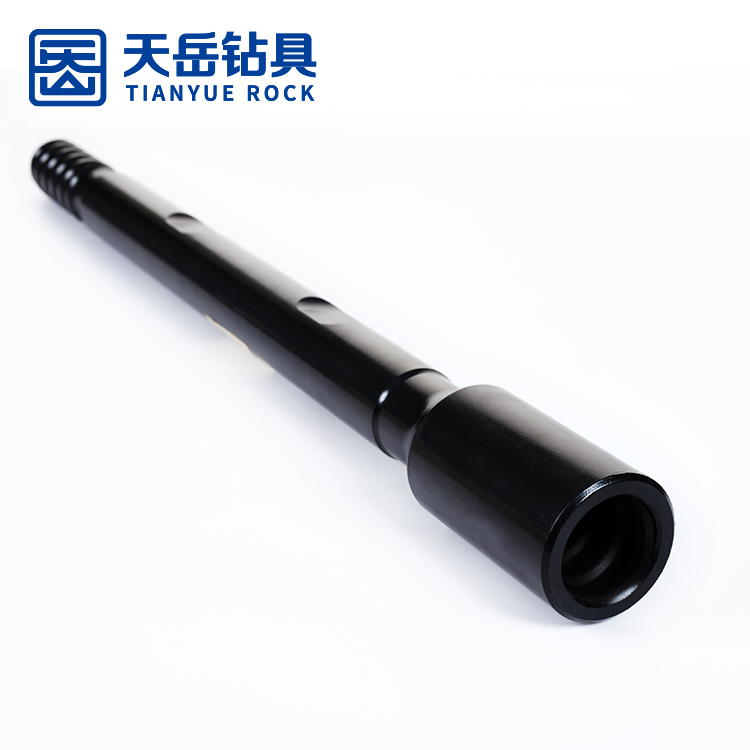

T51 Speed Rod: The Ultimate Drilling Connector for Efficiency and Durability

When it comes to top-tier rock drilling tools, T51 Speed Rod stands out as a critical component for maximizing productivity, minimizing downtime, and enhancing borehole accuracy. Built with superior alloy steel and engineered to withstand extreme geological conditions, the T51 Speed Rod is the go-to choice for mining, tunneling, and construction professionals who demand both speed and reliability.

What is a T51 Speed Rod?

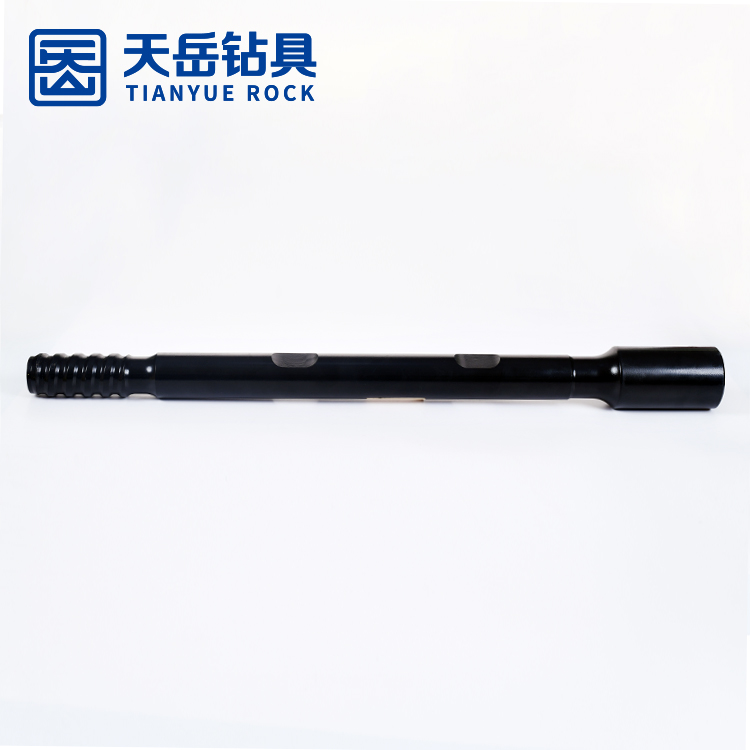

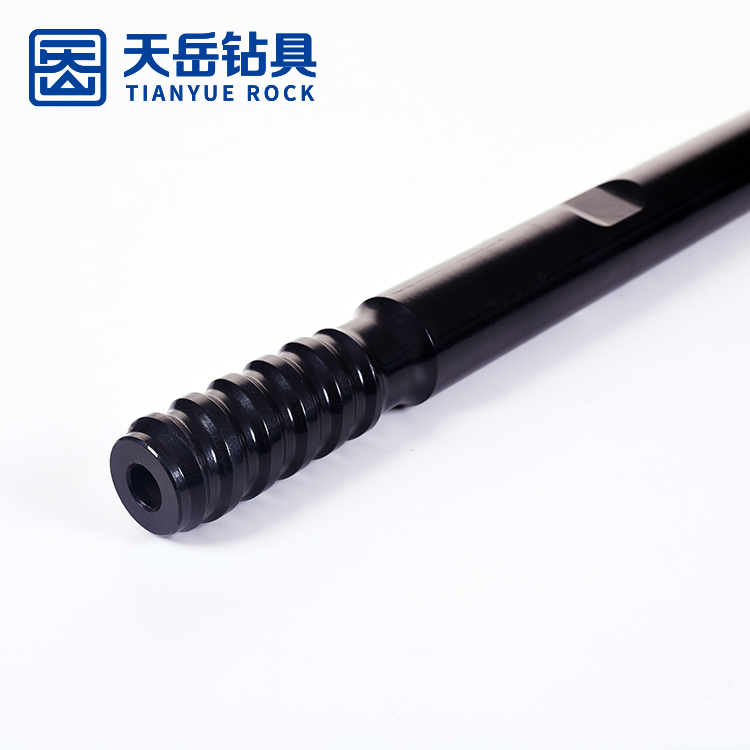

The T51 Speed Rod is a male-male threaded drill rod specifically designed for top hammer drilling applications. Known for its T51 thread profile—a robust trapezoidal shape optimized for strength and high-impact transmission—the T51 Speed Rod connects the rock drill to extension rods or drill bits in surface and underground drilling operations.

The "Speed" in its name highlights its quick coupling and decoupling ability, which contributes to faster drill string changes, increased efficiency, and reduced labor time in high-frequency drilling environments.

Key Features of T51 Speed Rod

Understanding the premium features of the T51 Speed Rod helps you see why it outperforms standard rods in real-world conditions:

High Tensile Strength Steel: The rod is manufactured from precision heat-treated alloy steel, giving it exceptional fatigue resistance and tensile strength.

Optimized Thread Design: The T51 thread ensures secure and seamless connections that minimize energy loss during percussive drilling.

Perfect Balance Between Flexibility and Rigidity: Designed to transmit high-frequency impact energy efficiently without excessive wear or deformation.

Superior Surface Finish: Advanced machining ensures a smooth finish, reducing thread galling and extending rod life.

Available in Multiple Lengths: Customizable to suit diverse drilling depths and equipment setups.

These attributes make the T51 Speed Rod ideal for heavy-duty applications in granite, basalt, quartzite, and other hard rock formations.

Applications of T51 Speed Rod

The T51 Speed Rod is widely used in:

Mining: Ideal for production drilling, bolting, and long-hole drilling in hard rock mining operations.

Tunneling and Civil Engineering: Used in horizontal drilling, slope stabilization, and blast-hole drilling for infrastructure development.

Quarrying: Enhances precision and productivity in open-pit quarry operations.

Hydroelectric and Railway Projects: Assists in large-scale foundational drilling and tunnel excavation.

By choosing the T51 Speed Rod, operators can ensure consistent drilling results across various geological conditions.

Why Choose T51 Speed Rod?

The market is full of drill rod options, but only the T51 Speed Rod offers the combination of longevity, performance, and speed that modern drilling projects demand. Here's why it’s the industry favorite:

Reduces Downtime: Fewer rod failures mean more time drilling and less time replacing.

Lowers Operating Costs: Durable design reduces the frequency of part replacements.

Enhances Safety: Secure thread connections decrease the likelihood of disconnections during operation.

Compatible with Top Brands: The T51 Speed Rod is fully compatible with drilling rigs from Epiroc, Sandvik, Furukawa, and other industry leaders.

Tips for Maintaining T51 Speed Rod Performance

To maximize the lifespan of your T51 Speed Rod, consider the following maintenance practices:

Regularly inspect thread conditions for wear or damage.

Apply proper thread lubricant to prevent galling.

Avoid mixing used rods with new ones to ensure even wear.

Clean threads before each use to maintain strong connections.

Conclusion

Whether you're drilling through tough granite in a quarry or laying the groundwork for a major infrastructure project, the T51 Speed Rod offers unmatched strength, reliability, and operational efficiency. Engineered for professionals who refuse to compromise, the T51 Speed Rod is not just a tool—it’s a performance booster that delivers measurable results in the field.

For buyers seeking the ultimate in rod quality and consistency, the T51 Speed Rod is the gold standard in drilling components.