T45 Speed Rod: Enhanced Performance for Precision Drilling

In modern rock drilling operations, tool reliability and performance are crucial to achieving cost-effective, efficient outcomes. The T45 Speed Rod has emerged as a premium choice in this category, offering unmatched durability, connection stability, and drilling accuracy. Purpose-built for top hammer drilling applications, the T45 Speed Rod is known for reducing downtime and maximizing drilling productivity in even the toughest geological conditions.

What Is a T45 Speed Rod?

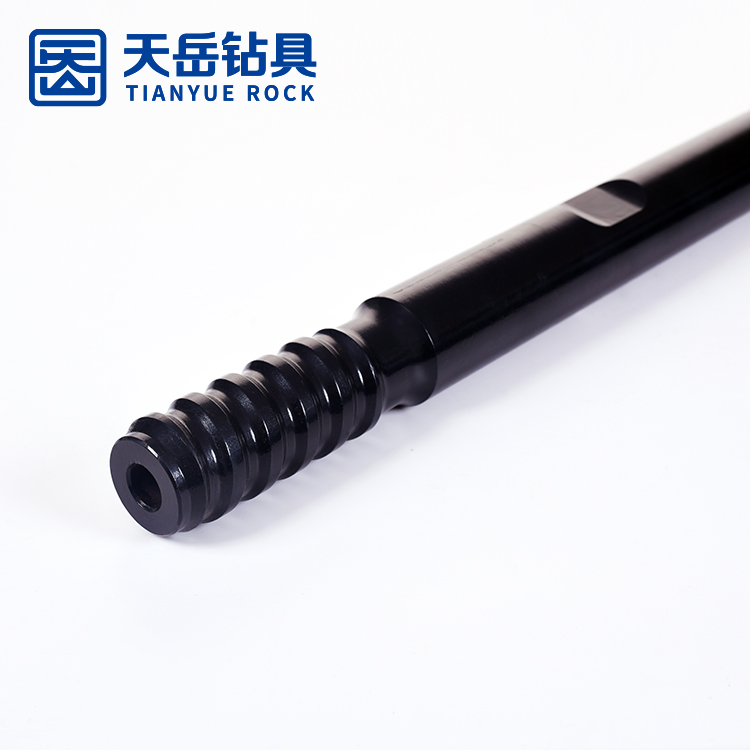

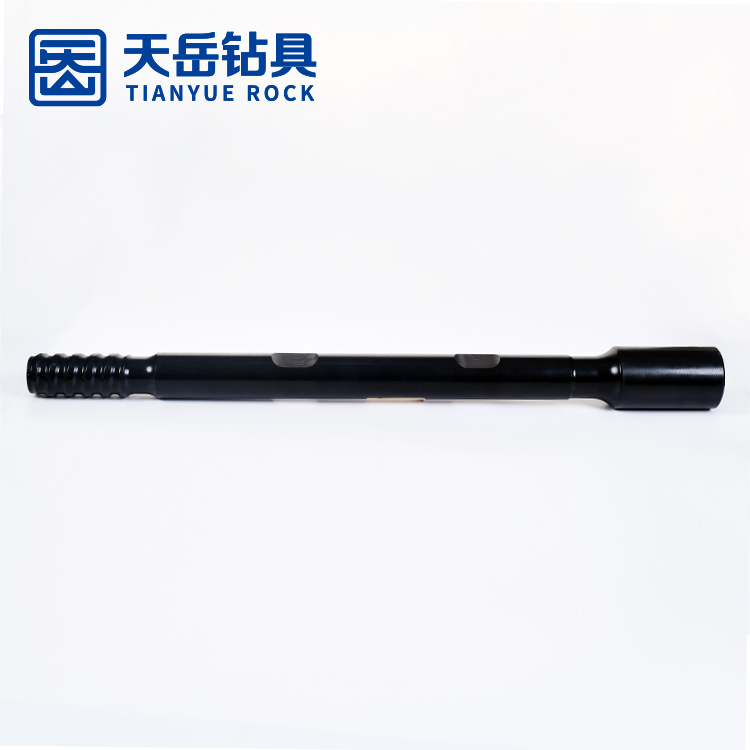

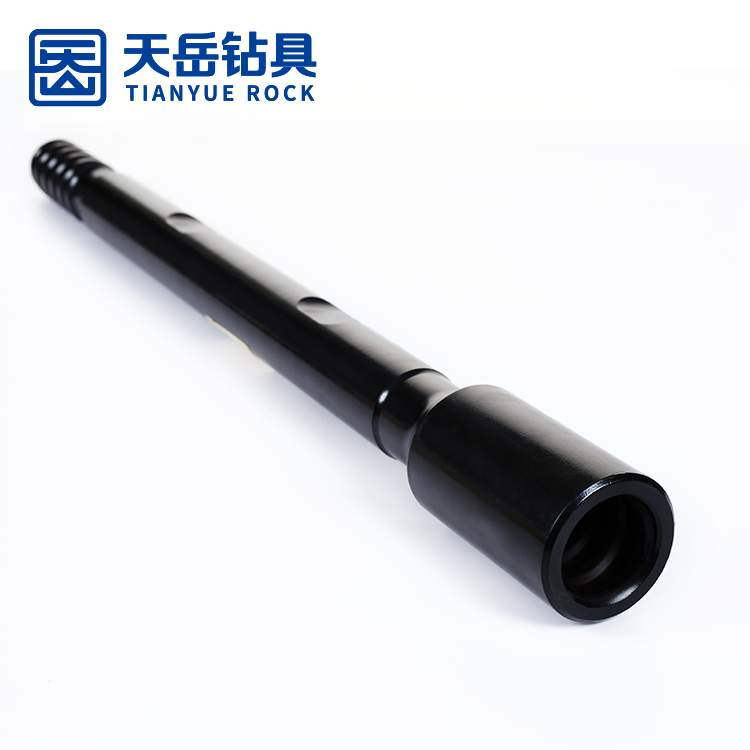

The T45 Speed Rod is a male-to-male threaded drill rod that utilizes the T45 thread profile—a heavy-duty trapezoidal design engineered for high-torque applications. Designed primarily for top hammer drilling systems, the T45 Speed Rod provides an optimal link between the rock drill and other components such as couplings or extension rods.

Its "Speed" designation highlights its capability for fast and secure connections, which translates into quicker drill string changes, shorter operational delays, and higher output.

Advantages of the T45 Speed Rod

Professionals across mining, construction, and quarrying industries consistently choose the T45 Speed Rod for the following standout features:

Premium Alloy Steel Composition: The rod is forged from high-strength steel with precision heat treatment, ensuring superior fatigue resistance and structural integrity.

Precision Thread Geometry: The T45 thread design offers a tight grip and minimizes energy loss, even in high-impact drilling environments.

Optimized for Impact Transmission: Engineered to efficiently transfer percussive energy from the drill to the bit without deformation.

Longer Lifespan: The rod's enhanced wear resistance results in lower maintenance frequency and reduced tool replacement costs.

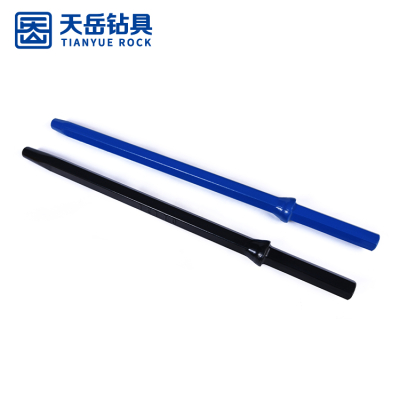

Corrosion-Resistant Finish: Ideal for harsh environments where rust and corrosion can affect tool performance.

Applications of the T45 Speed Rod

The T45 Speed Rod is widely utilized in a variety of applications:

Underground and Surface Mining: Perfect for production drilling and long-hole drilling in hard and abrasive rock formations.

Tunneling and Civil Engineering: Used in foundation work, slope anchoring, and pre-split drilling for infrastructure development.

Construction Projects: Enhances productivity in road construction, dam reinforcement, and building foundations.

Open Pit Quarrying: Supports blast hole drilling and stone cutting with precision.

Regardless of the industry, the T45 Speed Rod ensures consistent performance in demanding environments.

Why Choose the T45 Speed Rod?

Choosing the right drill rod is critical, and the T45 Speed Rod provides tangible benefits that make it a standout option:

Minimized Tool Failure: Built to resist bending, breakage, and thread stripping, even under extreme loads.

Faster Operations: Quick-change capabilities lead to smoother workflows and better use of man-hours.

Improved Accuracy: Reduced rod vibration ensures cleaner, more precise boreholes.

Broad Compatibility: The T45 Speed Rod fits seamlessly with drilling rigs from major manufacturers like Sandvik, Epiroc, and Atlas Copco.

Maintenance Tips for T45 Speed Rod Longevity

To keep your T45 Speed Rod in peak condition and extend its service life:

Apply thread grease before every use to minimize friction.

Inspect threads regularly for signs of wear or damage.

Store rods in dry environments to avoid rust and corrosion.

Use compatible coupling sleeves to prevent cross-threading and connection damage.

Conclusion

The T45 Speed Rod is a trusted solution for professionals who need strength, precision, and dependability in their drilling tools. From underground mines to civil engineering megaprojects, the T45 Speed Rod delivers superior results thanks to its cutting-edge design and construction.

If you are looking to increase productivity, reduce tool failure, and improve your overall drilling efficiency, the T45 Speed Rod is an investment that pays dividends from day one. Built for performance, built to last—the T45 Speed Rod is your drilling operation’s most reliable ally.