When it comes to hard rock drilling, performance and durability are everything. That’s where the R28 Thread Button Bit steps in as a game-changer. Engineered for precision, built for endurance, and trusted by drillers worldwide, this tool is an essential component in top hammer drilling systems—especially for tunneling, mining, and construction projects that demand high efficiency in confined or small-diameter environments.

If you’re in the market for a reliable, long-lasting, and cost-effective R28 Thread Button Bit, read on. This guide covers everything you need to know before choosing the right button bit for your drilling job.

🔧 What is an R28 Thread Button Bit?

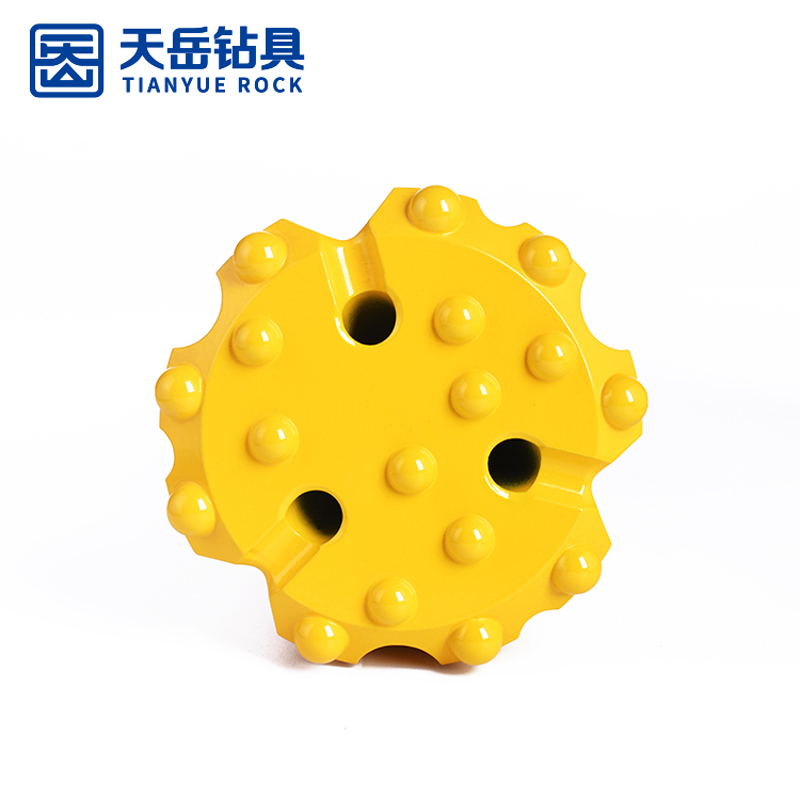

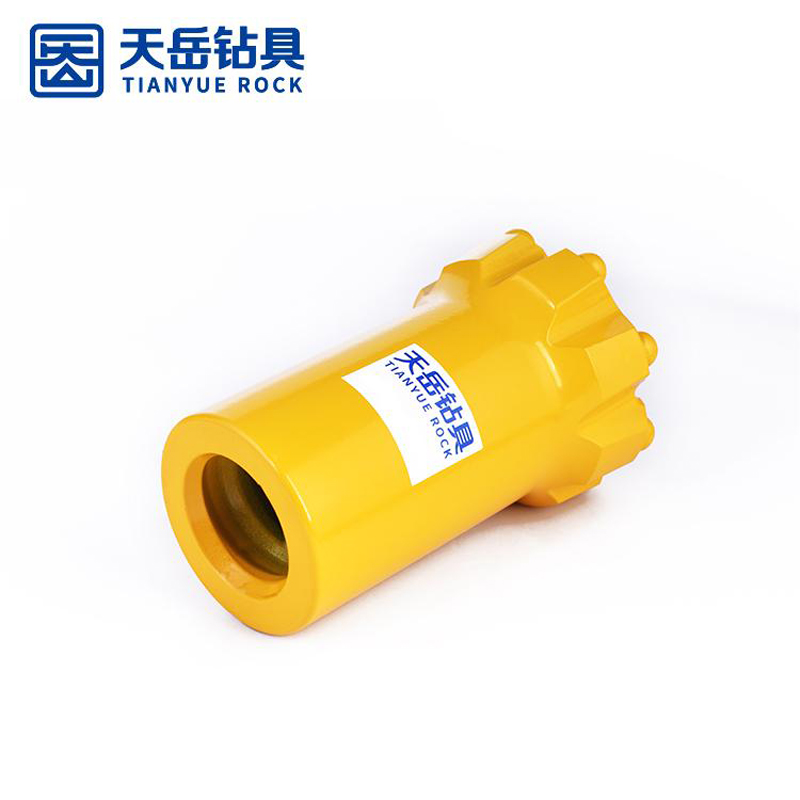

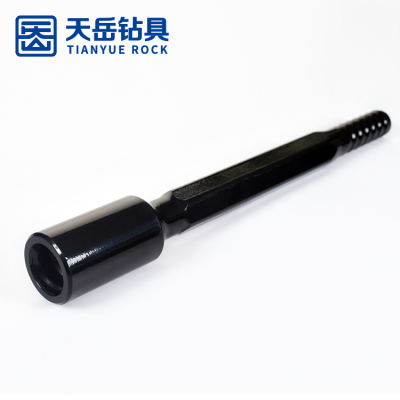

An R28 Thread Button Bit is a rock drilling tool with a 28mm round thread connection, designed to pair seamlessly with matching drill rods and shank adapters. It’s commonly used in top hammer drilling applications, especially in medium to hard rock conditions.

The bit features tungsten carbide buttons (spherical or ballistic) strategically embedded into a high-strength steel body to optimize penetration rates, reduce wear, and increase service life.

🛠 Key Features of R28 Thread Button Bit

✅ Thread Size: R28 (Round thread, 28mm)

✅ Diameter Range: Typically 38mm to 45mm

✅ Carbide Tips: Ballistic or spherical options

✅ Face Design: Flat face or drop center for different rock types

✅ Material: High-grade alloy steel + heat treatment

✅ Application: Underground mining, tunneling, small bench drilling

📈 Benefits of Using R28 Thread Button Bit

1. Superior Penetration in Hard Rock

Thanks to its high-impact carbide buttons and optimized flushing design, the R28 thread button bit delivers impressive penetration even in tough rock formations.

2. Precision Thread Fit

The R28 thread ensures secure engagement with the drill rod, reducing the risk of thread slippage and increasing energy transfer.

💬 "We’ve switched to R28 thread button bits on all our underground rigs—far less downtime due to jamming or thread wear. Totally worth the investment."

— Lars M., Operations Manager, Norway

3. Longer Tool Life

The heat-treated alloy body and wear-resistant carbide inserts allow this bit to withstand extreme working conditions, reducing the frequency of replacements.

4. Versatile Usage

From small-diameter boreholes to confined-space drilling, the R28 thread button bit adapts perfectly to variable geological settings.

💬 "As a geotechnical contractor, we need bits that handle tight angles and tricky formations. R28 button bits get the job done, time after time."

— Samuel A., GeoDrill Services, Australia

🏗 Where is R28 Thread Button Bit Commonly Used?

| Industry | Use Case |

|---|

| Mining | Underground drifting and bolting |

| Tunneling | Horizontal and vertical excavation |

| Geotechnical | Soil testing and sampling in rock layers |

| Construction | Foundation boreholes, anchor holes |

| Quarrying | Small-diameter blast hole drilling |

🧠 How to Choose the Right R28 Button Bit

When selecting the R28 thread button bit, consider the following:

Rock Hardness: Use spherical buttons for abrasive, hard formations; ballistic for faster penetration in fractured rock.

Face Design: Drop center bits are better for hole deviation control, while flat faces work well for consistent vertical drilling.

Air Flushing: Ensure the bit has adequate air flushing holes to remove cuttings and reduce heat buildup.

📦 Available Specifications

Diameter Options: 38mm / 41mm / 45mm

Button Configuration: 7 or 9 buttons (depending on diameter)

Button Type: Ballistic / Spherical / Parabolic

Thread Fit: R28 (precision-machined)

Weight: Approx. 0.8kg to 1.5kg

💬 "We order R28 bits in bulk for our African mining operations. Excellent longevity and value. No complaints in three years!"

— Jean-Claude T., Procurement Head, DRC

🔍 Frequently Asked Questions

❓ Is R28 suitable for all rock types?

Yes, it’s effective in soft to hard rock. However, carbide type and bit design should be matched to rock conditions.

❓ Can I use R28 bits with other thread systems?

No, the R28 thread is specific. You must use compatible drill rods and shanks.

❓ How often should I replace an R28 bit?

That depends on the rock type and drilling hours, but quality bits can last 3,000 to 5,000 drill meters in typical conditions.

🌎 Global Market Demand

Due to increasing demand for small-diameter and high-precision drilling tools, the R28 thread button bit is gaining popularity across Europe, Southeast Asia, and South America.

It’s particularly in demand for:

✅ Final Thoughts: Why Choose R28 Thread Button Bit?

If your goal is precise, efficient, and cost-effective drilling, the R28 thread button bit is an industry favorite. It strikes the perfect balance between tool longevity, penetration speed, and thread reliability—making it a smart investment for any serious driller.

💬 "From quality to pricing to field performance—R28 thread button bits check every box for us."

— Tomás R., Lead Engineer, Chile

Button bit | Diameter | No×button diameter | Flushing hole | Weight

approx kg |

TIANYUE P/N |

| mm | inch | Front | Gauge | Angle | Front | Side |

![Thread Button Bit Thread Button Bit]() | Spherical Buttons |

37

| 1 29/64 | 2×7 | 5×9 | 30° | 1 | 1 | 0.5 | 1431-37R28-27/59-45-41 |

| 38 | 1 1/2 | 2×8 | 4×9 | 30° | 1 | 2 | 0.6 | 1431-38R28-28/49-45-41 |

| 38 | 1 1/2 | 2×7 | 5×9 | 30° | 1 | 1 | 0.6 | 1431-38R28-27/59-45-41 |

| 41 | 1 5/8 | 2×8 | 5×9 | 35° | 1 | 1 | 0.7 | 1431-41R28-28/59-45-41 |

| 43 | 1 11/16 | 2×9 | 5×9 | 35° | 1 | 2 | 0.8 | 1431-43R28-29/59-45-41 |

| 45 | 1 3/4 | 2×9 | 5×10 | 30° | 1 | 2 | 0.9 | 1431-45R28-29/510-45-41 |

| 45 | 1 3/4 | 3×8 | 6×9 | 35° | 1 | 3 | 0.9 | 1431-45R28-38/69-45-41 |

| Parabolic Buttons |

| 37 | 1 29/64 | 2×7 | 5×9 | 30° | 1 | 1 | 0.5 | 1431-37R28-27/59-45-51 |

| 38 | 1 1/2 | 2×8 | 4×9 | 30° | 1 | 2 | 0.6 | 1431-38R28-28/49-45-51 |

| 38 | 1 1/2 | 2×7 | 5×9 | 30° | 1 | 1 | 0.6 | 1431-38R28-27/59-45-51 |

| 41 | 1 5/8 | 2×8 | 5×9 | 35° | 1 | 1 | 0.7 | 1431-41R28-28/59-45-51 |

| 43 | 1 11/16 | 2×9 | 5×9 | 35° | 1 | 2 | 0.8 | 1431-43R28-29/59-45-51 |

| 45 | 1 3/4 | 2×9 | 5×10 | 30° | 1 | 2 | 0.9 | 1431-45R28-29/510-45-51 |

| 45 | 1 3/4 | 3×8 | 6×9 | 35° | 1 | 3 | 0.9 | 1431-45R28-38/69-45-51 |

| 48 | 1 7/8 | 2×9 | 5×11 | 30° | 1 | 2 | 1 | 1431-48R28-29/511-45-51 |

| 48 | 1 7/8 | 3×8 | 6×9 | 35° | 1 | 3 | 1 | 1431-48R28-38/69-45-51 |

Product |

Button Bit |

| Other Names | Button drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bit |

| Material | 23CrNi3Mo |

| Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

| Thread | R25, R28, R32, R35, R38, T38, T45, T51, ST58, ST68, GT60, SR28, SR35... |

| Bit Type | Thread Button Bit,Retrac Button Bit,Reaming Button Bit,Cross Bit,Chisel Bit |

| Skirt Design | Standard skirt, Retrac skirt, Straightrac skirt, Heavy duty skirt |

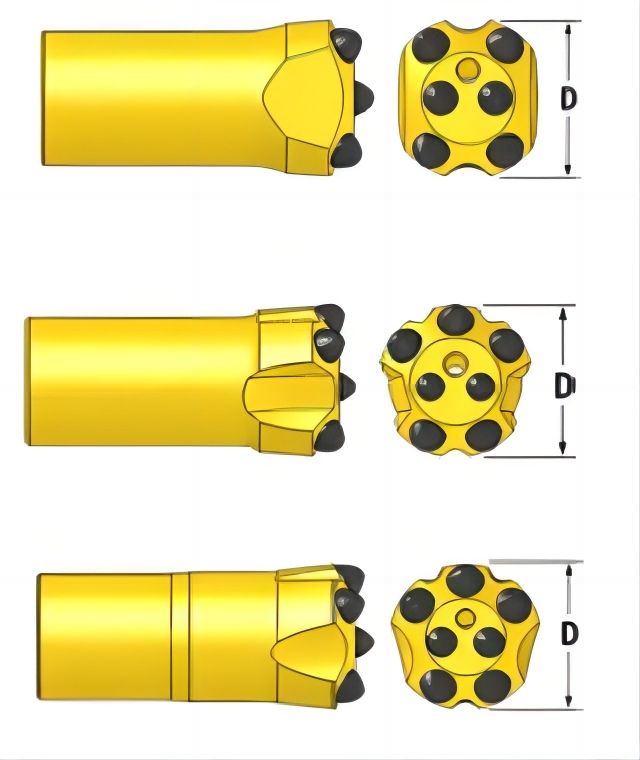

| Face Design | Flat face, Drop center face, Convex face, Reaming type, Cross type |

| Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons |

| Head Diameter | 28mm~152mm |

| Custom Design | Size,Color |

| Face Design | Application |

![Thread Button Bit Thread Button Bit]() | Flat face button drill bits are suitable for all rock conditions, especially for the rock with higher hardness and higher abrasiveness. Such as granite and basalt. |

![Thread Button Bit Thread Button Bit]() | Convex Face button bits are designed for fast penetration rates in softer rock. |

![Thread Button Bit Thread Button Bit]() | Drop center button drill bits are mainly suitable for the rock with low hardness, low abrasiveness, and good integrity. The bits can drill straighter holes. |

![Thread Button Bit Thread Button Bit]() | Normal Skirt

For drilling in very hard and abrasive rock formations. |

![Thread Button Bit Thread Button Bit]() | Retract Skirt

For drilling in loose,broken or fissured rock where it is difficult to retract the drill string due to the hole collapse. |

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

![Thread Button Bit Thread Button Bit]()