Road Mining Teeth: Essential Components for Efficient and Durable Road Construction

In road construction and mining operations, the efficiency and durability of equipment are crucial for achieving high productivity. Among the most vital tools in road milling and mining machinery are Road Mining Teeth. These teeth are designed to withstand extreme conditions, ensuring that road construction and maintenance projects proceed smoothly. In this article, we will explore the importance, features, applications, and benefits of Road Mining Teeth, and why they are indispensable for the success of your project.

What Are Road Mining Teeth?

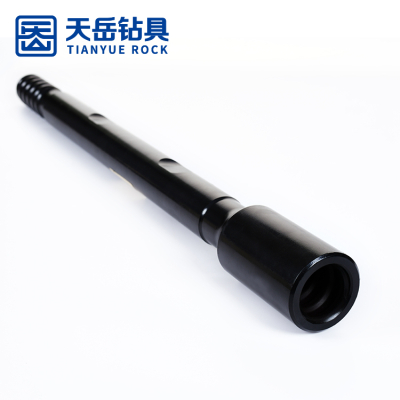

Road Mining Teeth are specialized cutting tools attached to road milling machines, soil stabilizers, and mining equipment. These teeth are designed to cut, grind, and pulverize road surfaces, asphalt, concrete, and other materials during road construction, maintenance, or mining operations. Made from high-quality materials such as tungsten carbide, Road Mining Teeth are built to last and endure the toughest working environments.

Key Features of Road Mining Teeth

The durability and efficiency of Road Mining Teeth are attributed to their design and material construction. Here are some key features that make these teeth stand out:

High-Quality Alloy Materials: The Road Mining Teeth are made from durable materials, such as tungsten carbide and steel, offering resistance to wear and tear. This construction ensures that the teeth can handle high-impact and abrasive conditions, extending their lifespan.

Precision Engineering: Road Mining Teeth are engineered with precision to ensure efficient cutting and grinding performance. Their sharp edges and optimized shape make them capable of tackling even the most challenging road surfaces with ease.

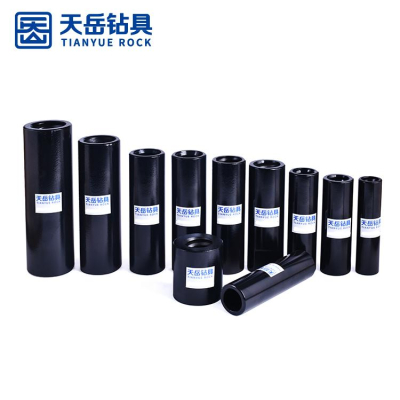

Adaptability: These teeth are available in various sizes and designs to fit different types of road milling machines, soil stabilizers, and mining equipment. Their versatility makes them suitable for a wide range of applications, from road repair to mining operations.

Easy Installation and Maintenance: Road Mining Teeth are designed for easy installation, making them simple to replace when worn out. Their low maintenance requirements ensure that the machinery operates smoothly and with minimal downtime.

Applications of Road Mining Teeth

Road Mining Teeth are used in a variety of applications, primarily in road construction, maintenance, and mining. Some of the key applications include:

Road Milling: During road construction and repair projects, Road Mining Teeth are used for milling asphalt and concrete surfaces. Their efficient cutting ability ensures that roads are prepared for resurfacing or repaving, making the milling process faster and more effective.

Soil Stabilization: In soil stabilization projects, Road Mining Teeth are used to break down compacted soils, facilitating the mixing of stabilizing agents with the ground. This ensures that the soil is properly conditioned for construction projects, such as foundations and embankments.

Mining Operations: Road Mining Teeth are also employed in mining equipment to cut through rock and mineral deposits. Their tough construction allows them to perform efficiently in harsh mining conditions, reducing downtime and improving overall productivity.

Surface Preparation: For projects requiring precise surface preparation, such as trenching and clearing, Road Mining Teeth are used to ensure smooth and accurate results, readying the surface for further construction or development.

Benefits of Road Mining Teeth

Choosing high-quality Road Mining Teeth offers several benefits that contribute to the success of your project:

Enhanced Durability: The use of high-strength materials such as tungsten carbide ensures that Road Mining Teeth can withstand the harshest environments, including high abrasion and impact. This extended durability reduces the frequency of replacements, saving you time and money.

Improved Efficiency: The precision engineering of Road Mining Teeth allows for efficient cutting and grinding, significantly improving the performance of road milling machines and other equipment. This enhanced efficiency leads to faster project completion and lower operational costs.

Cost-Effective: Although Road Mining Teeth may have a higher initial cost compared to standard teeth, their durability and efficiency lead to lower long-term maintenance and replacement costs. The reduced downtime and increased productivity further contribute to cost savings.

Reduced Downtime: The easy installation and maintenance of Road Mining Teeth ensure that equipment stays operational with minimal interruptions. This helps maintain the flow of construction and mining projects, reducing the risk of delays.

Versatility: The adaptability of Road Mining Teeth makes them suitable for various types of road milling and mining machines, enhancing their utility in diverse applications.

How to Choose the Right Road Mining Teeth

Selecting the appropriate Road Mining Teeth is crucial to maximizing performance and minimizing downtime. Here are some factors to consider when choosing Road Mining Teeth:

Type of Project: Consider the specific needs of your project, such as road milling, mining, or soil stabilization. Different applications require different types of teeth, so choose those that are optimized for your task.

Material: The material of the Road Mining Teeth plays a significant role in their performance. Tungsten carbide teeth, for example, offer superior hardness and wear resistance, making them ideal for abrasive surfaces.

Size and Design: Ensure that the teeth are compatible with your equipment. The size and design of the teeth should match the specifications of the road milling machine or mining equipment to ensure a secure fit and optimal performance.

Manufacturer: Choose a reputable manufacturer known for producing high-quality Road Mining Teeth. Quality control and consistent performance are essential to ensure that the teeth perform as expected over the long term.

Conclusion

Road Mining Teeth are essential components for road construction, maintenance, and mining operations. Their durability, efficiency, and versatility make them indispensable for professionals in the industry. By investing in high-quality Road Mining Teeth, you can improve the performance of your equipment, reduce operational costs, and ensure that your project is completed on time and within budget.

Whether you are working on road milling, soil stabilization, or mining, the right Road Mining Teeth will enhance the efficiency and longevity of your machinery. Make sure to choose the best products that match your specific needs to maximize the success of your operations.