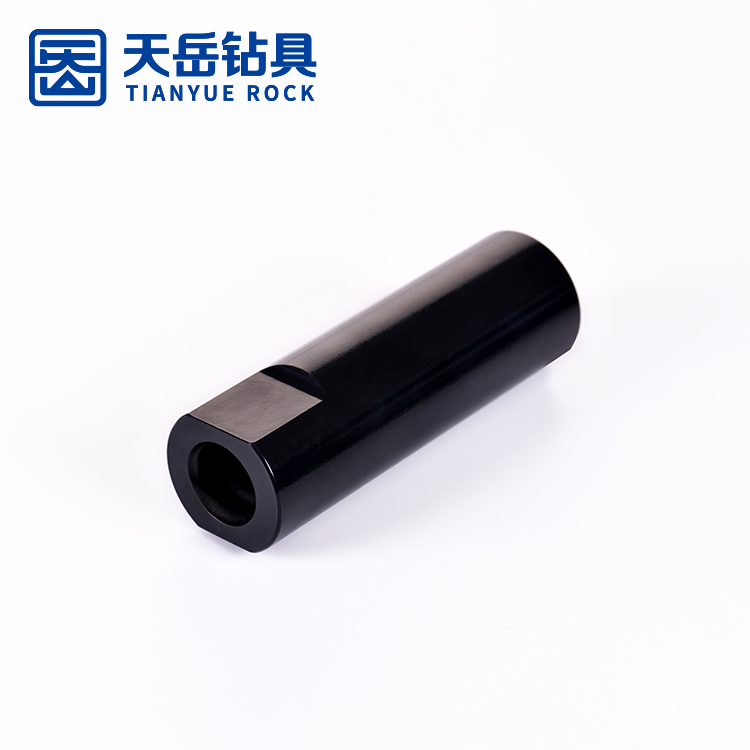

In the world of drilling and mining, precision and durability are paramount. T38 Coupling Sleeves are a critical component that plays a key role in ensuring the efficiency and safety of drilling operations. These high-quality coupling sleeves are designed to provide a secure connection between drill rods, offering stability and strength in challenging conditions.

What Are T38 Coupling Sleeves?

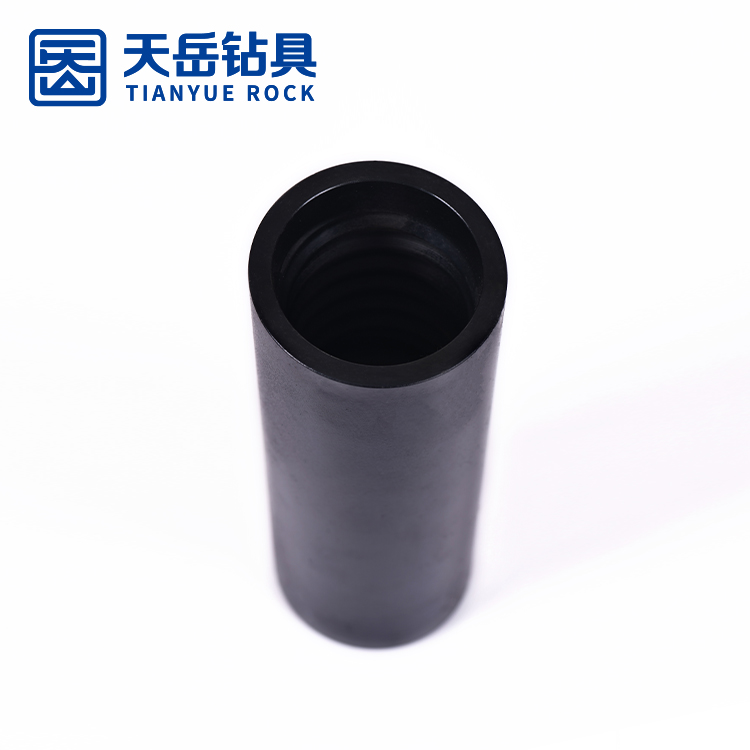

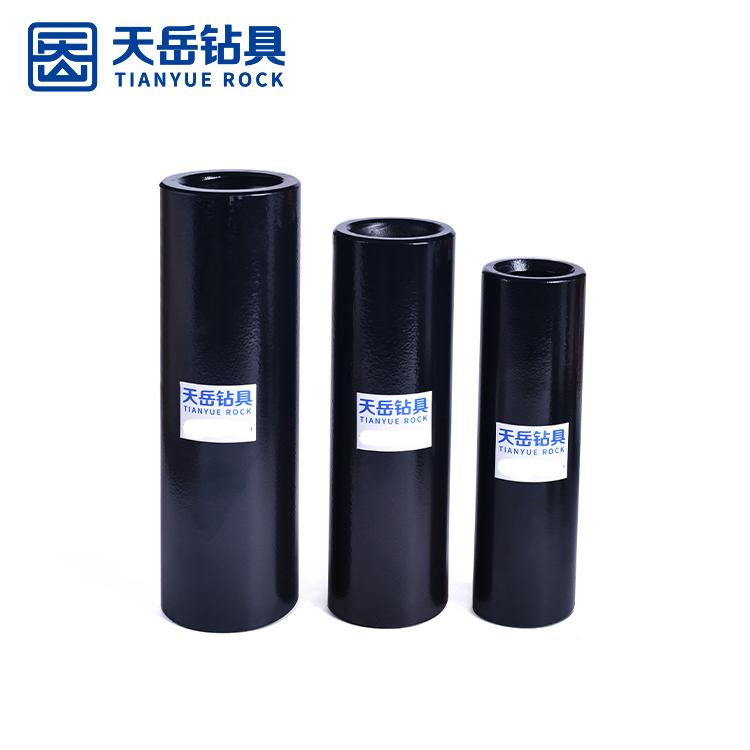

T38 Coupling Sleeves are specialized connectors used in drilling operations to join T38 drill rods. They are manufactured from high-strength materials such as alloy steel to withstand the extreme pressures and forces encountered during drilling and mining. T38 Coupling Sleeves are essential for extending the length of the drill string and maintaining the integrity of the drilling equipment.

The Role of T38 Coupling Sleeves in Drilling Operations

T38 Coupling Sleeves serve several crucial purposes:

Connecting Drill Rods: The primary function of T38 Coupling Sleeves is to join two T38 drill rods securely, ensuring a continuous and reliable drilling process.

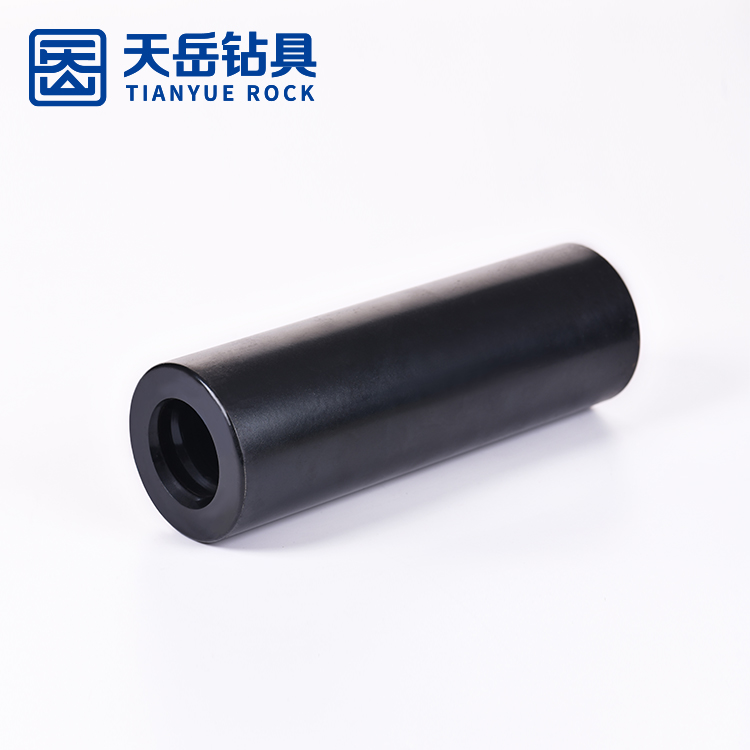

Strength and Durability: Made from high-grade steel, these sleeves are built to endure high torque, heavy impact, and constant pressure in harsh underground environments.

Efficient Drilling: By maintaining a strong and stable connection, T38 Coupling Sleeves help prevent breaks or failures that could disrupt the drilling process, minimizing downtime and improving operational efficiency.

Safety Assurance: The coupling sleeves are designed to prevent accidents and provide a secure fit, ensuring the safety of workers and the protection of equipment.

Features of T38 Coupling Sleeves

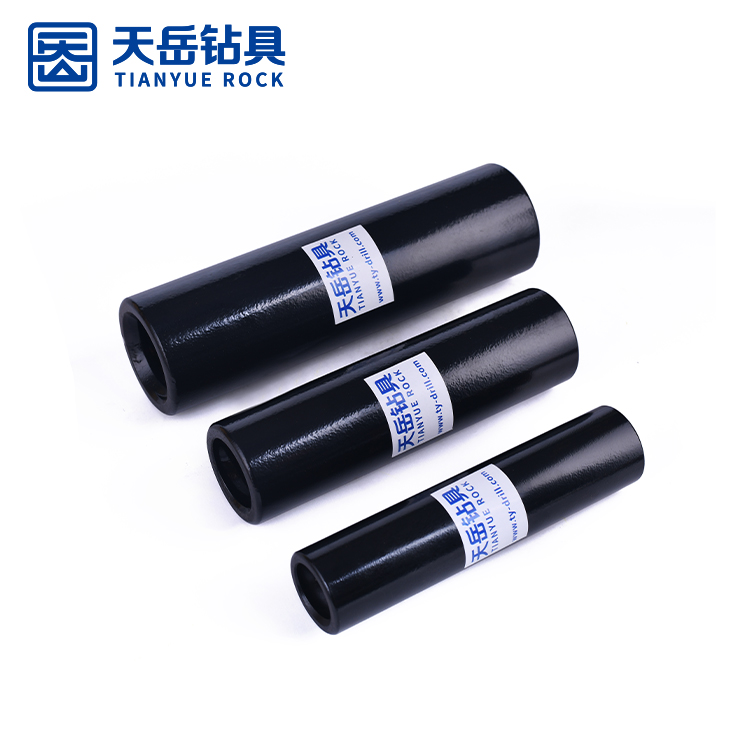

When selecting T38 Coupling Sleeves, it’s important to consider their key features:

High Strength: These sleeves are made from premium materials that offer exceptional tensile and fatigue strength, which ensures they can handle tough drilling conditions.

Corrosion Resistance: T38 Coupling Sleeves are often coated or treated to resist corrosion, extending their service life and maintaining the performance of the drilling system.

Precision Engineering: The threads on the coupling sleeves are precisely engineered to ensure a perfect fit, preventing slippage or loosening during operation.

Compatibility: These sleeves are designed specifically for use with T38 drill rods, ensuring seamless integration with other drilling equipment.

Benefits of Using T38 Coupling Sleeves

The use of T38 Coupling Sleeves provides a range of benefits in drilling and mining operations:

Enhanced Performance: By ensuring a secure and durable connection, T38 Coupling Sleeves improve the overall performance of drilling rigs, allowing for faster and more efficient drilling.

Reduced Downtime: Their robust design minimizes the likelihood of connection failures or equipment breakdowns, reducing costly downtime and maintenance.

Increased Safety: The secure and reliable connection provided by the sleeves helps prevent accidents, ensuring the safety of workers on-site.

Cost-Effective: T38 Coupling Sleeves are built to last longer, reducing the need for frequent replacements and contributing to cost savings over time.

Applications of T38 Coupling Sleeves

T38 Coupling Sleeves are used across a variety of industries and applications, including:

Mining: Essential for drilling deep boreholes and exploration drilling in mining operations.

Geotechnical Drilling: Used for soil testing, core sampling, and other geotechnical investigations.

Construction: Commonly used in foundation drilling, pile driving, and other construction-related activities.

Water Well Drilling: Important for joining drill rods in water well drilling projects.

Choosing the Right T38 Coupling Sleeves

When selecting T38 Coupling Sleeves, it’s important to ensure they meet the specific needs of your drilling operations. Factors such as material quality, thread compatibility, and corrosion resistance should be considered. Additionally, sourcing T38 Coupling Sleeves from reputable manufacturers ensures reliability, safety, and long-lasting performance.

Final Thoughts

T38 Coupling Sleeves are indispensable components in the world of drilling and mining. Their role in ensuring stable, secure, and efficient connections between drill rods makes them a vital part of any drilling operation. By choosing high-quality T38 Coupling Sleeves, operators can enhance performance, reduce downtime, and ensure the safety of workers, all while maximizing the life of their equipment.