Foundation Drill: Essential Equipment for Deep and Stable Construction

🚧 Power Up Your Project with a High-Performance Foundation Drill

When it comes to building high-rises, bridges, wind farms, or heavy infrastructure, the need for deep and stable foundations is non-negotiable. That’s where a foundation drill becomes a mission-critical machine. Engineered for precision and strength, the foundation drill is essential for boring deep holes in soil, rock, and mixed geological layers.

Whether you are a civil engineering contractor or a piling equipment dealer, choosing the right foundation drill ensures long-term structural integrity and efficiency on-site.

🔍 What is a Foundation Drill?

A foundation drill is a type of heavy-duty drilling machine used in deep foundation construction to bore vertical holes into the earth for piling or caisson construction. These drills can penetrate soft soil, dense sand, gravel, and bedrock, making them suitable for a wide range of foundation systems.

🛠️ Applications of Foundation Drill

Foundation drills are widely used across multiple industries and infrastructure projects:

Using a foundation drill guarantees reliable support for structures exposed to dynamic loads and environmental stress.

⚙️ Types of Foundation Drills

There are several types of foundation drill machines based on their drilling method and depth capability:

Kelly Bar Rotary Drills

Continuous Flight Auger (CFA) Drills

Hydraulic Casing Rotators

Core Barrel Foundation Drill

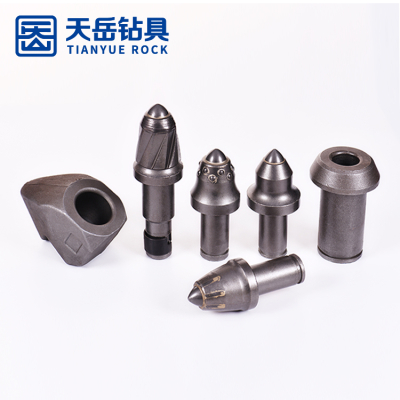

All these types fall under the broader category of foundation drill machinery, each optimized for different site conditions.

🧪 Technical Parameters Example

💡 Why Choose a High-Quality Foundation Drill?

A top-tier foundation drill ensures:

✅ Precise hole verticality and depth control

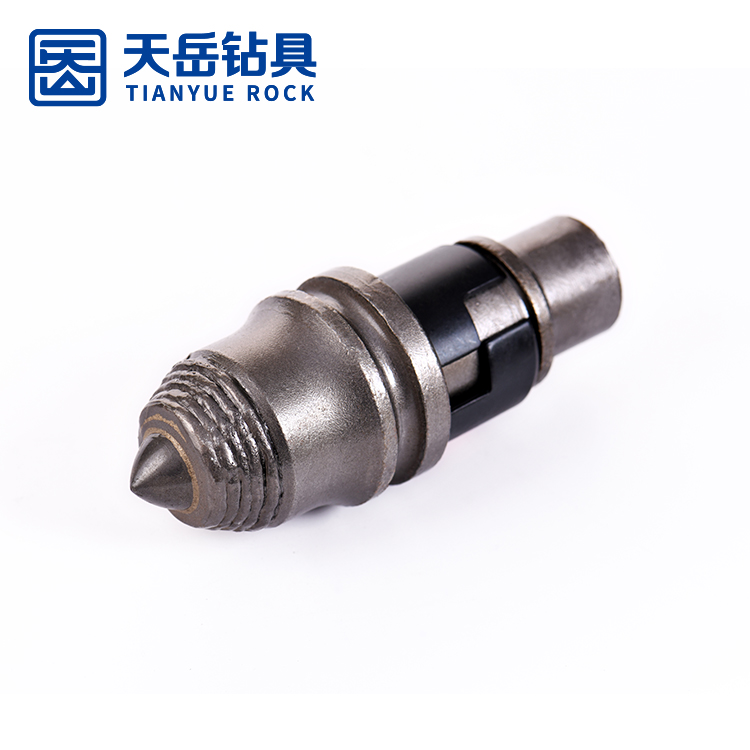

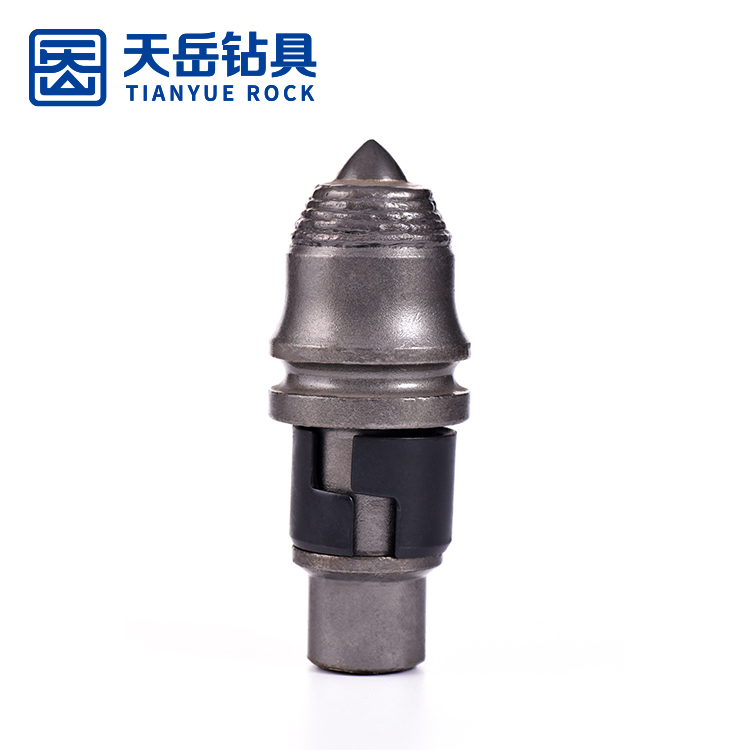

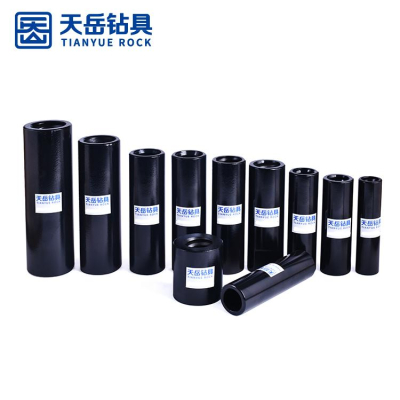

✅ Compatibility with multiple auger or casing tools

✅ Fuel efficiency and eco-compliance

✅ Long service life in harsh construction environments

✅ Lower operating costs due to better torque efficiency