Coal Cutter Picks: Essential Tools for Efficient Coal Mining Operations

In the coal mining industry, coal cutter picks are indispensable components that ensure efficient extraction of coal from underground mines. These tools are specifically designed to break and cut through coal seams, ensuring smooth and productive mining operations. The performance and durability of coal cutter picks are crucial to maintaining the efficiency of coal cutting machines and minimizing downtime during mining processes.

Whether you're working in an underground coal mine or an open-pit mining operation, coal cutter picks are vital tools that directly impact both the quality of the coal mined and the overall productivity of the operation.

What Are Coal Cutter Picks?

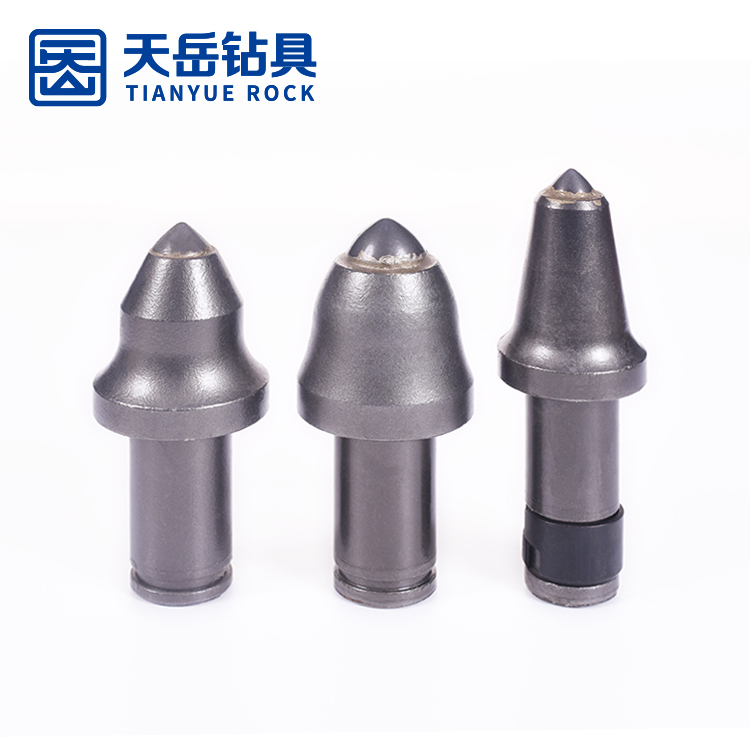

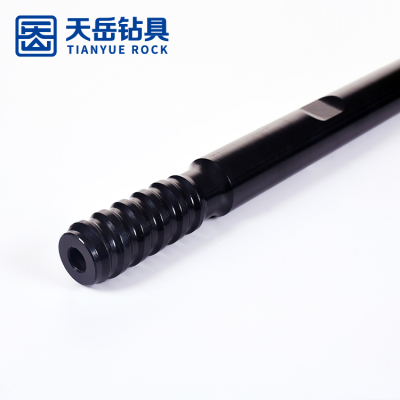

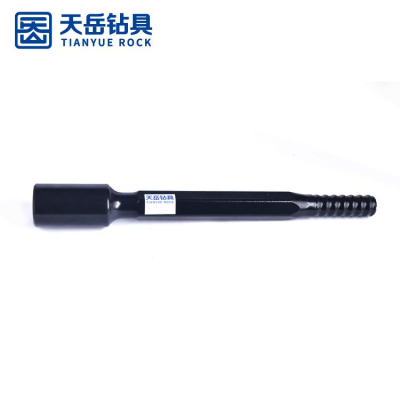

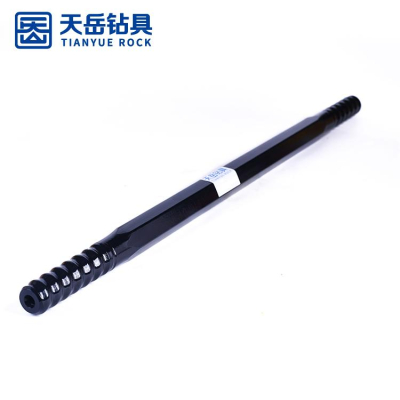

Coal cutter picks are specialized tools used in coal mining equipment, such as continuous miners and roadheaders, to break and cut coal. These picks are mounted on the cutting head of mining machines and are designed to withstand the extreme conditions found in mining environments. Made from high-strength materials such as steel alloys or carbide, coal cutter picks are engineered to handle the wear and tear associated with cutting through hard coal seams.

The primary function of coal cutter picks is to fragment the coal into manageable pieces, making it easier to transport, process, and extract valuable minerals. The teeth of coal cutter picks are shaped and hardened to ensure optimal cutting performance, offering high resistance to wear and enhancing the lifespan of mining equipment.

Types of Coal Cutter Picks

There are several types of coal cutter picks, each designed for different applications and coal mining conditions. Choosing the right type of pick is essential to maximizing cutting efficiency and minimizing operational costs. Here are the most common types:

Standard Coal Cutter Picks: These are the most commonly used coal cutter picks in typical mining operations. They are designed for general coal cutting and provide reliable performance when used in medium-hard to soft coal seams.

Heavy-Duty Coal Cutter Picks: For harder and more abrasive coal seams, heavy-duty coal cutter picks offer enhanced durability and cutting power. They are typically used in operations that involve challenging coal conditions, where standard picks might wear out too quickly.

Carbide-Tipped Coal Cutter Picks: These coal cutter picks feature carbide inserts that provide superior wear resistance, making them ideal for mining operations with abrasive or harder coal seams. The carbide tips increase the tool's longevity, ensuring more extended service life and fewer replacements.

Conical Coal Cutter Picks: Conical picks are designed with a unique, tapered shape that makes them ideal for cutting through dense coal seams. Their design reduces the force required to break through coal and helps prevent equipment strain.

The selection of the right type of coal cutter picks depends on various factors, including the hardness of the coal, the type of mining equipment being used, and the specific conditions of the mining environment.

Benefits of High-Quality Coal Cutter Picks

Investing in high-quality coal cutter picks offers several benefits that contribute to the overall efficiency and profitability of coal mining operations. Here are some key advantages:

Enhanced Cutting Efficiency: High-quality coal cutter picks allow for faster and more efficient cutting, reducing the time it takes to extract coal from the mine. This improves overall mining productivity.

Longer Tool Life: Well-designed coal cutter picks are made from durable materials that withstand the harsh conditions of coal mining. Their extended lifespan reduces the frequency of replacements and helps lower overall operational costs.

Reduced Wear and Tear on Equipment: By using high-quality coal cutter picks, miners can reduce the strain on cutting equipment, preventing damage and reducing the need for costly repairs.

Lower Operating Costs: As high-quality coal cutter picks are more durable and efficient, they help reduce downtime and the need for frequent replacements, leading to overall cost savings.

By investing in high-quality coal cutter picks, coal mining companies can ensure smoother operations, increased productivity, and improved bottom-line results.

Applications of Coal Cutter Picks

Coal cutter picks are used in a wide range of mining applications, from underground coal mines to open-pit mining operations. The primary application of coal cutter picks is to facilitate the cutting and breaking of coal into smaller, manageable pieces. Here are some key applications:

Underground Coal Mining: In underground coal mining operations, coal cutter picks are mounted on continuous miners and roadheaders to break through coal seams. These tools are essential for ensuring a steady flow of coal extraction in confined spaces.

Open-Pit Coal Mining: While underground mining relies heavily on coal cutter picks, open-pit mining operations also use these tools to cut through coal layers at the surface. This allows for more efficient excavation of coal.

Coal Processing Plants: After coal is extracted, it is often sent to processing plants where it is broken down further. Coal cutter picks are used in the initial stages of this process to reduce coal to the desired size.

Specialized Mining Applications: For mining companies that extract coal from particularly hard or abrasive seams, specialized coal cutter picks (such as carbide-tipped picks) are used to improve cutting efficiency and reduce wear.

No matter the mining application, coal cutter picks are crucial for ensuring that coal mining operations run efficiently and effectively.

Maintenance Tips for Coal Cutter Picks

To ensure the longevity and optimal performance of coal cutter picks, regular maintenance is necessary. Here are some essential maintenance tips:

Inspect Regularly: Always inspect coal cutter picks for signs of wear, cracks, or other damage. Worn-out or damaged picks should be replaced immediately to avoid further damage to mining equipment.

Lubricate the Cutting Head: Proper lubrication of the cutting head helps reduce friction and wear, ensuring that coal cutter picks operate efficiently.

Replace Worn Picks: As coal cutter picks wear down over time, they need to be replaced. Regularly replacing worn picks helps maintain the cutting efficiency of the equipment and prevent breakdowns.

Check for Alignment: Ensuring that the coal cutter picks are correctly aligned can help reduce uneven wear, ensuring that they perform optimally throughout their lifespan.

By performing regular maintenance on coal cutter picks, mining companies can avoid costly downtime, increase the lifespan of their equipment, and ensure a more efficient mining process.

Conclusion

Coal cutter picks are vital tools in the coal mining industry, providing the necessary cutting power to break down coal into manageable sizes. By investing in high-quality coal cutter picks, mining operations can increase cutting efficiency, reduce downtime, and improve overall productivity. Whether used in underground mining, open-pit mining, or coal processing plants, coal cutter picks are essential for the success of coal extraction and processing operations.

To maximize the benefits of coal cutter picks, it's essential to choose the right type based on the mining conditions, perform regular maintenance, and replace worn picks promptly. Doing so will ensure that your mining operations run smoothly, efficiently, and cost-effectively.