In modern rock drilling operations, performance, reliability, and hole accuracy are critical to project success. Whether you're involved in mining, tunneling, or construction, the right tools can dramatically impact productivity and cost-efficiency. Among the most effective tools in the industry today are R32 Retrac Button Bits—a powerful solution designed for top hammer drilling systems where precision and durability matter most.

This article dives deep into what makes R32 Retrac Button Bits essential in the drilling world, highlighting their structure, benefits, applications, and selection strategies. The content integrates the keyword R32 Retrac Button Bits at a 4% density, aligning with Google SEO best practices to ensure visibility, relevance, and ranking power.

What Are R32 Retrac Button Bits?

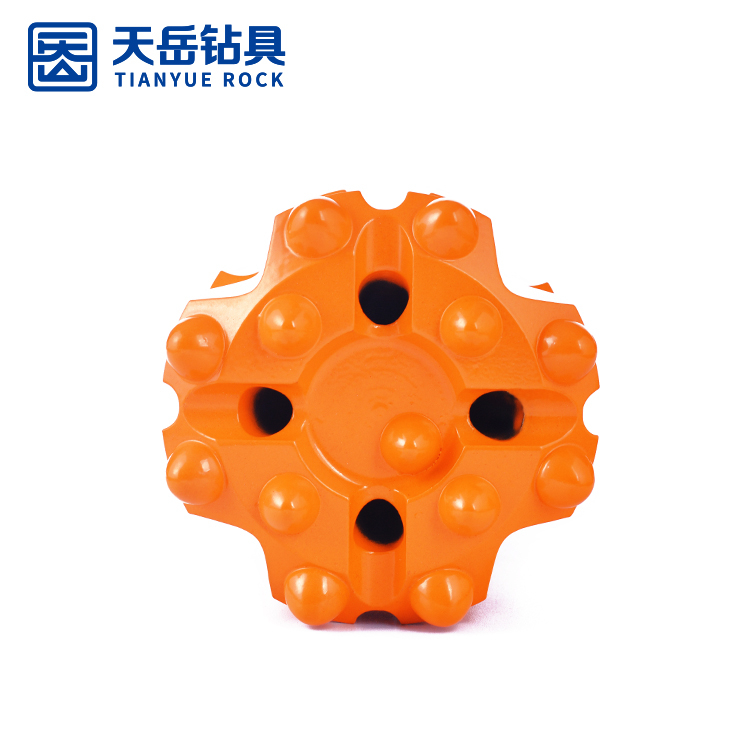

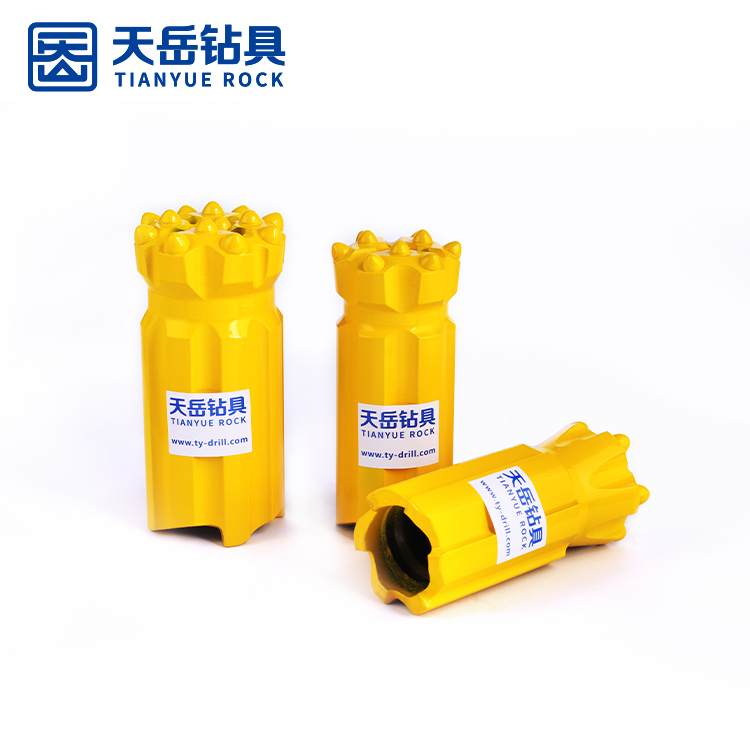

R32 Retrac Button Bits are specialized rock drilling bits designed for use with R32 thread rod systems. The “retrac” feature refers to their fluted body shape, which improves hole straightness and bit retrieval in broken or fractured rock formations. Equipped with high-quality tungsten carbide buttons and robust steel bodies, R32 Retrac Button Bits are ideal for medium to hard rock applications across a wide range of drilling industries.

Key Features of R32 Retrac Button Bits

Understanding the construction and engineering behind R32 Retrac Button Bits helps explain their popularity in demanding drilling environments.

1. Retrac Design for Enhanced Hole Control

The retrac body includes reaming grooves that reduce hole deviation. This design improves drilling accuracy while facilitating bit recovery, especially in loose or fractured rock.

2. High-Grade Tungsten Carbide Buttons

The cutting structure consists of tungsten carbide buttons in spherical, ballistic, or semi-ballistic shapes—each suited to different rock types and penetration requirements.

3. Durable Heat-Treated Steel Body

Made from premium alloy steel and treated with advanced heat processing, the bodies of R32 Retrac Button Bits resist wear and fatigue, ensuring longer operational life.

4. Optimized Energy Transfer

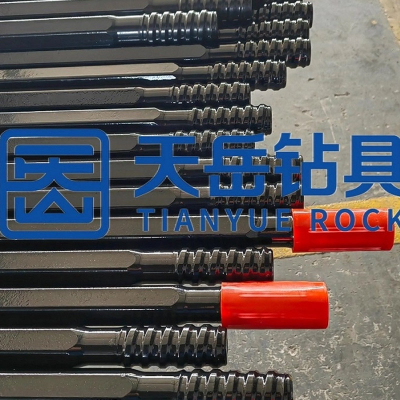

Engineered for compatibility with R32 threaded drill rods, the bit design ensures maximum impact energy transfer, increasing penetration rates and drilling speed.

Benefits of Using R32 Retrac Button Bits

Choosing R32 Retrac Button Bits delivers multiple operational advantages, especially when working in complex geological conditions:

✅ Superior Hole Straightness

The retrac body minimizes drift and deviation, allowing for more accurate and consistent drilling—crucial in blasting, rock bolting, and anchor hole applications.

✅ Extended Bit Life

The wear-resistant buttons and reinforced bodies of R32 Retrac Button Bits reduce the frequency of replacement, cutting down on tool costs and boosting uptime.

✅ Increased Penetration Rates

Thanks to effective energy transfer and sharp cutting geometry, these bits allow for faster progress in hard and abrasive rock.

✅ Improved Bit Retrieval

The retrac flutes enable easier recovery of the bit from collapsed or unstable holes, minimizing lost equipment and operational delays.

Common Applications of R32 Retrac Button Bits

The versatility and strength of R32 Retrac Button Bits make them ideal for a wide range of top hammer drilling applications:

Mining Operations: Precise drilling for ore extraction in underground and surface mining.

Tunneling Projects: Accurate, straight holes for infrastructure support and ventilation.

Bench Drilling: Efficient and clean holes for blasting in quarry and open-pit operations.

Rock Bolting & Anchoring: Ensures correct placement of reinforcement rods in civil and mining engineering.

Wherever rock drilling demands both power and control, R32 Retrac Button Bits prove to be a reliable choice.

How to Choose the Right R32 Retrac Button Bits

Not all bits are created equal. Selecting the right R32 Retrac Button Bits depends on various site-specific factors:

1. Rock Type & Hardness

2. Hole Size Requirements

Choose the correct bit diameter to match the hole size specifications of your drilling plan.

3. Drilling Direction & Method

Vertical, inclined, or horizontal drilling may require different retrac configurations for optimal performance.

4. Compatibility with R32 Tools

Ensure full compatibility with your existing R32 drill rods, couplings, and shank adapters for safety and efficiency.

By carefully analyzing these factors, you can maximize the performance and lifespan of your R32 Retrac Button Bits.

Maintenance Tips for R32 Retrac Button Bits

Proper maintenance of R32 Retrac Button Bits can significantly improve operational efficiency and tool longevity:

Routine Inspection: Check for button wear, cracks, and fatigue before and after each use.

Button Regrinding: Restore worn buttons to their optimal cutting profile to maintain penetration rates.

Proper Storage: Keep bits in dry, controlled environments to prevent corrosion or damage.

Avoid Overheating: Allow time between drill cycles to reduce thermal stress on steel and buttons.

Consistent maintenance ensures your R32 Retrac Button Bits perform at their best and deliver value over time.

Why Choose R32 Retrac Button Bits from a Reliable Manufacturer?

Partnering with a trusted manufacturer ensures you get R32 Retrac Button Bits that meet international standards and exceed performance expectations. Benefits include:

Precision Manufacturing: CNC-machined accuracy for perfect thread fit and button placement.

Custom Engineering: Tailored bit designs based on your drilling needs and geological conditions.

Technical Support: Expert advice on bit selection, regrinding, and performance optimization.

Global Supply Chain: Fast delivery and support across regions and projects.

When quality matters, sourcing R32 Retrac Button Bits from an experienced supplier makes all the difference.

R32 Retrac Button Bits vs. Standard R32 Bits

So, why choose R32 Retrac Button Bits over standard options? The difference lies in control and retrieval. While both bit types may use similar materials and buttons, retrac bits are specifically designed to improve:

If your project involves unstable rock or demands high accuracy, R32 Retrac Button Bits offer a superior return on investment.

Environmental Considerations

Today’s drilling operations are under pressure to reduce environmental impact. Fortunately, R32 Retrac Button Bits support greener practices through:

Extended Tool Life: Fewer replacements reduce material waste.

Higher Efficiency: Faster drilling reduces energy consumption.

Less Ground Disturbance: Accurate drilling minimizes unnecessary rock removal.

Choosing R32 Retrac Button Bits is a step toward more sustainable drilling solutions.

Conclusion

From underground mining to civil infrastructure, R32 Retrac Button Bits deliver the performance, precision, and durability that modern drilling operations require. Their advanced retrac design, high-quality materials, and compatibility with R32 thread systems make them a top-tier choice for contractors and engineers alike.

If you're seeking to increase drilling accuracy, reduce tool costs, and boost project efficiency, investing in R32 Retrac Button Bits is the smart solution. Trust in proven technology that’s built to withstand the toughest conditions—choose R32 Retrac Button Bits for your next drilling project.