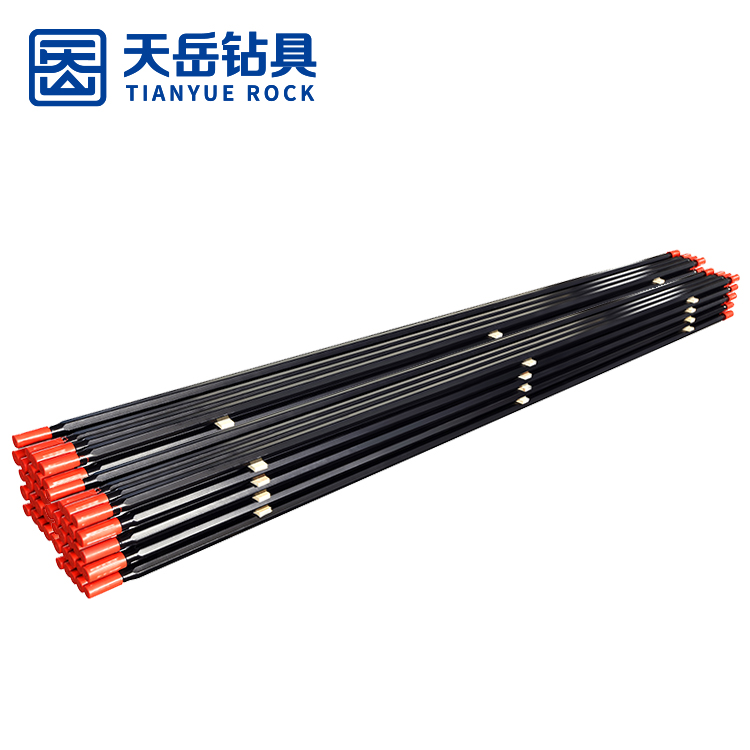

In demanding rock drilling applications, the R32 drifter rod stands out as an essential tool for efficiency, durability, and precision. Designed specifically for top hammer drifters, the R32 drifter rod delivers exceptional impact resistance and energy transfer, making it the go-to solution for mining, construction, and tunneling projects worldwide.

If you want to enhance your drilling productivity and reduce equipment downtime, the R32 drifter rod is your trusted partner for consistent, reliable performance.

🔩 What Is an R32 Drifter Rod?

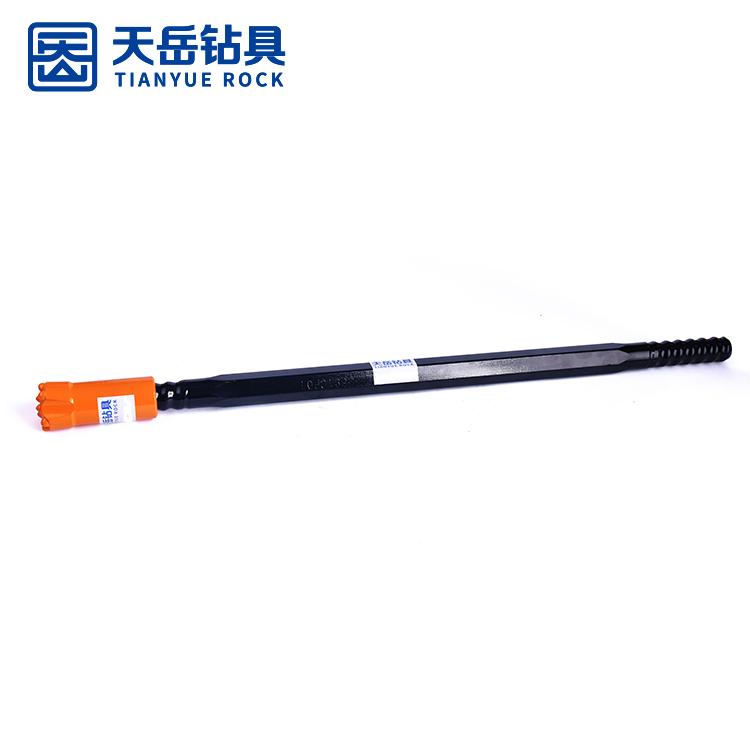

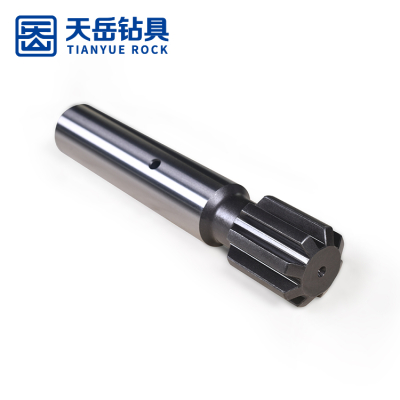

An R32 drifter rod is a heavy-duty steel rod engineered to connect the drill bit to the drifter machine in top hammer drilling systems. With a robust R32 thread profile, this rod ensures optimal torque transmission and shock absorption, enabling deep and accurate drilling in rock formations.

Crafted from high-grade alloy steel and subjected to precise heat treatment, the R32 drifter rod offers outstanding hardness and wear resistance, suited to harsh drilling environments.

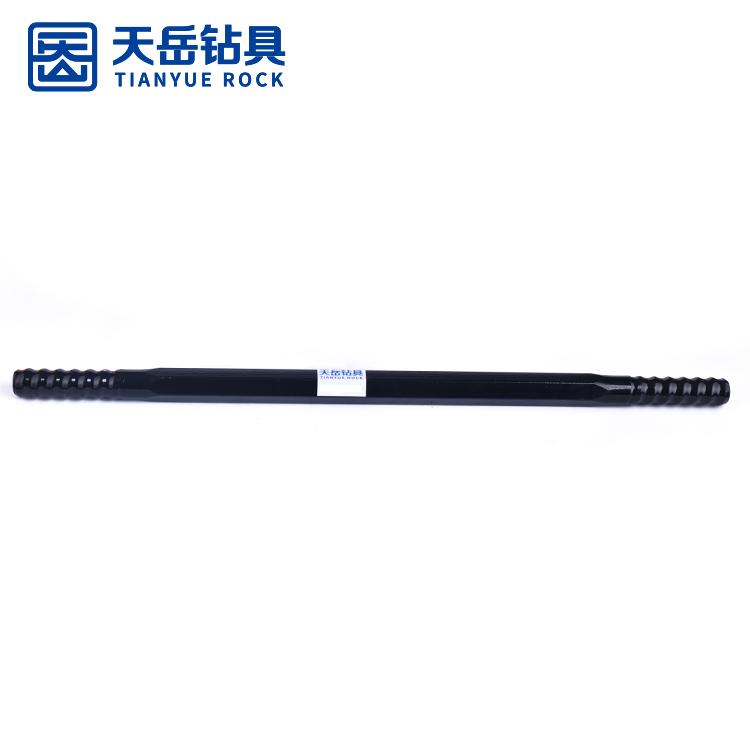

⭐ Key Features of the R32 Drifter Rod

Thread Type: R32 (32mm) male/female or male/male options

Length Options: Typically 750mm to 1,500mm, customizable lengths available

Material: Premium alloy steel with heat treatment for toughness

Hardness Level: HRC 55–60 for superior wear resistance

Design: Straightness tolerance within 0.5mm/m

Compatibility: Fits a wide range of drifter machines, including Atlas Copco, Sandvik, and Furukawa

✅ Benefits of Using the R32 Drifter Rod

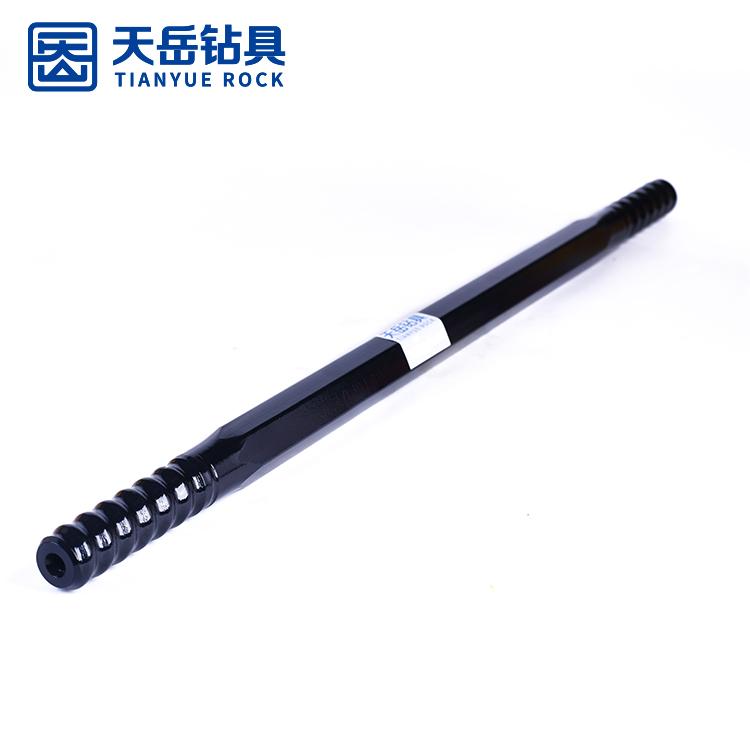

1. Enhanced Drilling Efficiency

The R32 drifter rod provides excellent energy transfer from the drifter to the drill bit, resulting in faster penetration rates and reduced fuel consumption.

2. Exceptional Durability

Constructed from heat-treated alloy steel, the R32 drifter rod resists wear, fatigue, and deformation, significantly extending rod life and lowering replacement frequency.

3. Superior Shock Absorption

The R32 thread profile and robust steel body absorb drilling vibrations and shocks, protecting your equipment and minimizing operational disruptions.

4. Easy Handling and Maintenance

The R32 drifter rod features precise machining for smooth thread engagement and disassembly, simplifying field maintenance and reducing downtime.

5. Wide Industry Application

Ideal for mining, tunneling, and construction projects where reliable drilling tools are a must.

🛠️ Typical Applications of the R32 Drifter Rod

Underground mining and tunneling: Achieves precise and efficient drilling in confined spaces

Quarrying operations: Supports fast rock fragmentation with reliable performance

Construction foundations: Ensures stable boreholes for anchoring and blasting

Hydropower and infrastructure projects: Suitable for demanding drilling environments

Road construction and rock excavation: Delivers consistent results in challenging geological conditions

📊 R32 Drifter Rod Compared to Other Drilling Rods

| Feature | R32 Drifter Rod | R38 Rod | R28 Rod |

|---|

| Thread Diameter | 32mm | 38mm | 28mm |

| Typical Length Range | 750–1500mm | 900–1800mm | 600–1200mm |

| Hardness Level | HRC 55–60 | HRC 55–60 | HRC 50–58 |

| Usage | Top hammer drifters | Top hammer | Light drilling |

| Strength & Durability | High | Very High | Moderate |

The R32 drifter rod is perfectly balanced for medium-duty drilling with excellent energy efficiency and longevity.

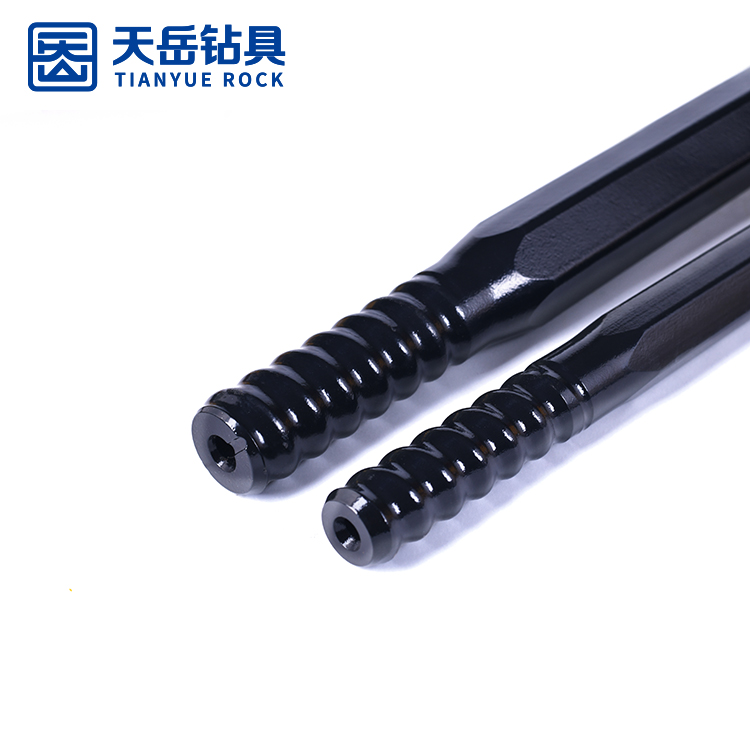

🧩 How to Maintain Your R32 Drifter Rod for Maximum Performance

Regularly inspect threads for wear or damage

Apply thread lubricant before assembly to prevent galling

Rotate rods in your drilling set to ensure even wear

Clean rods after each use to remove debris and prevent corrosion

Store rods properly in a dry, flat location to avoid bending or rusting

These simple practices will prolong the service life of your R32 drifter rod and maximize drilling productivity.

🛒 Where to Buy Reliable R32 Drifter Rods?

When purchasing R32 drifter rods, select suppliers who offer:

ISO-certified quality assurance

Customized length and thread options

Competitive pricing with bulk order discounts

Fast worldwide shipping and responsive technical support

Detailed product specifications and testing reports

Choose trusted manufacturers specializing in drilling consumables to ensure you receive premium-quality R32 drifter rods designed for demanding projects.

🚀 Upgrade Your Drilling Operation with R32 Drifter Rods Today!

Don't settle for inferior drilling tools that cause frequent breakdowns and lost productivity. Investing in the R32 drifter rod guarantees:

Increased drilling speed and efficiency

Reduced equipment wear and replacement costs

Enhanced operational safety and reliability

Take the next step to elevate your drilling projects with R32 drifter rods engineered for superior performance.

📞 Ready to Order?

Contact us now to get expert advice, pricing quotes, and fast delivery options on premium R32 drifter rods. Equip your drilling rigs with the best to ensure your project success.