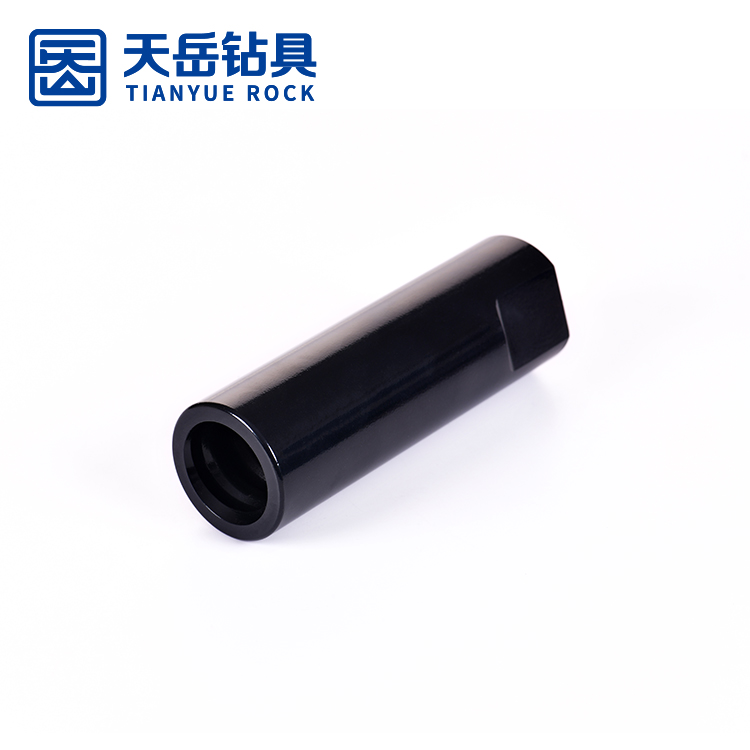

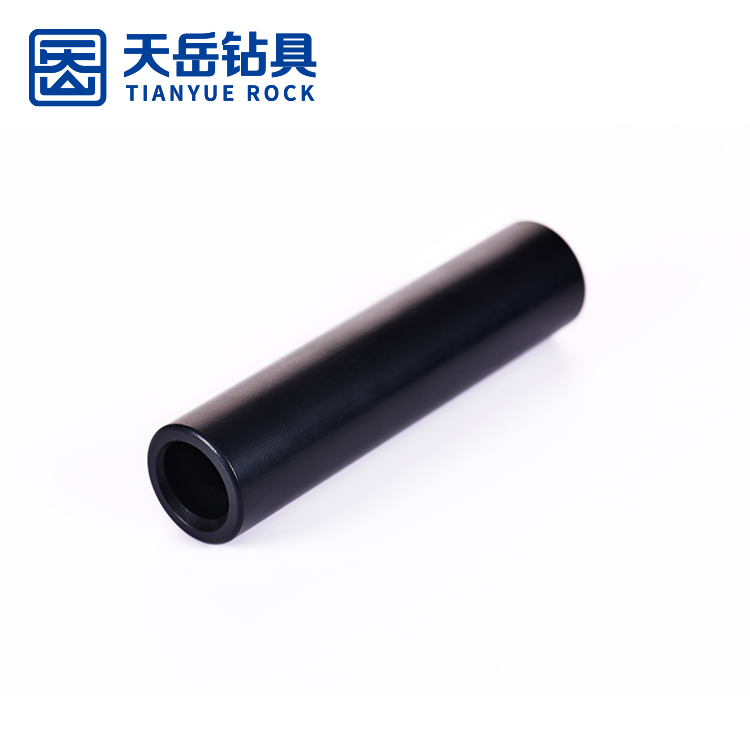

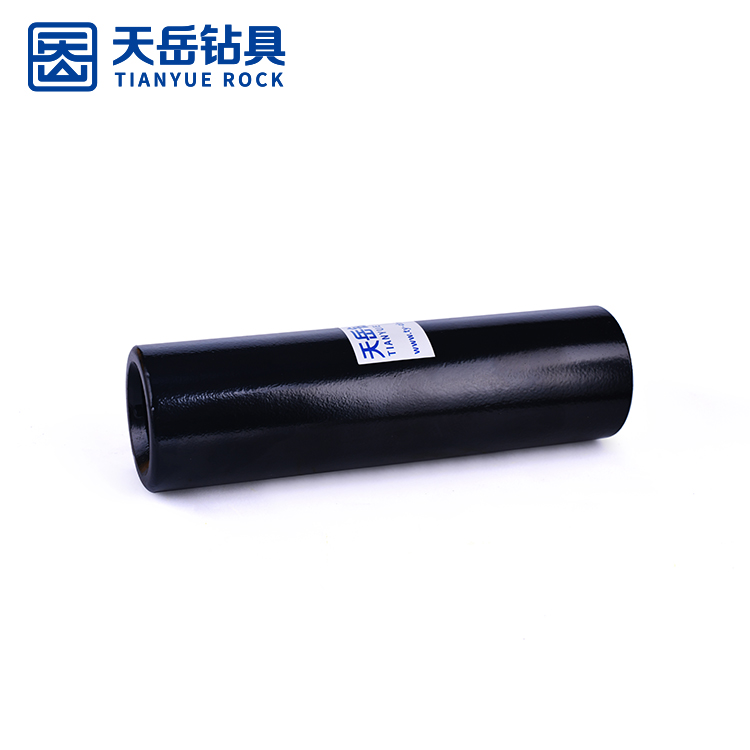

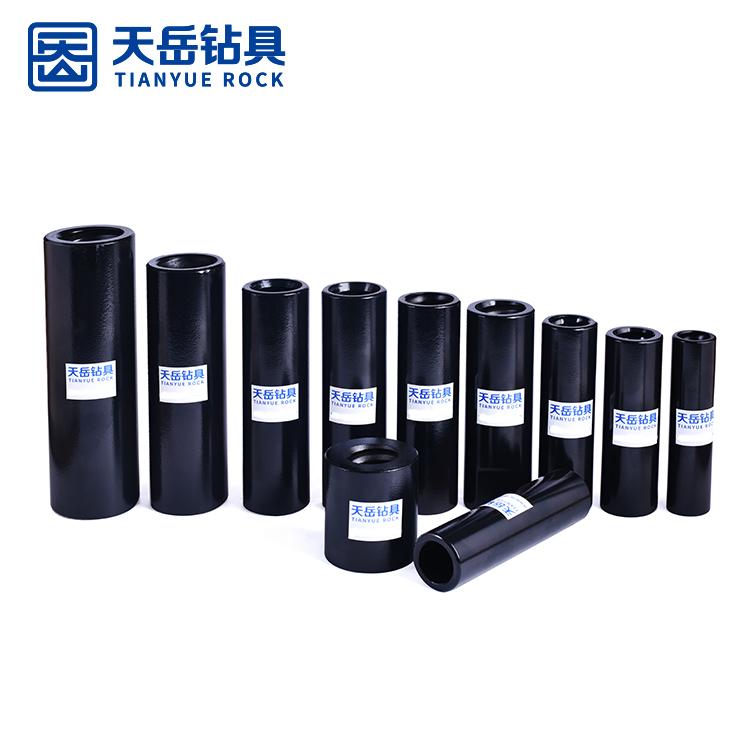

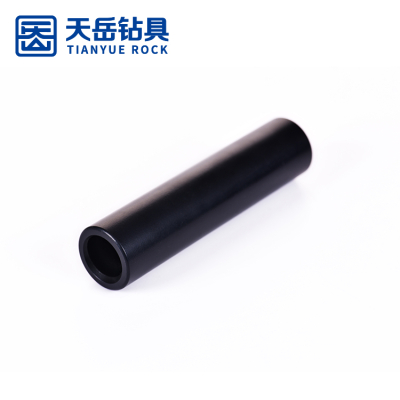

Coupling Sleeve is a high-performance coupling sleeve designed for mechanical systems, dedicated to providing outstanding durability and reliability. Whether in industrial production lines or transportation equipment, Coupling Sleeve ensures the smooth operation of mechanical transmission systems, offering comprehensive protection for your equipment.

Product | Coupling Sleeves |

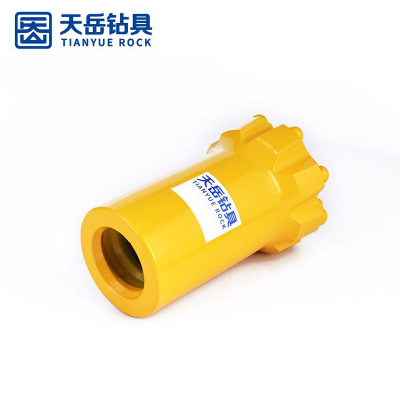

Other Names | Coupling sleeves,Drill bit adapter,Rock drill tools,Tophammer drill tools,Drifter drill tools,Coupling,Drill rod couplings,Drill coupling sleeves |

Material | 23CrNi3Mo |

Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

Thread | R25, R32, R35, R38, T38, T45, T51 |

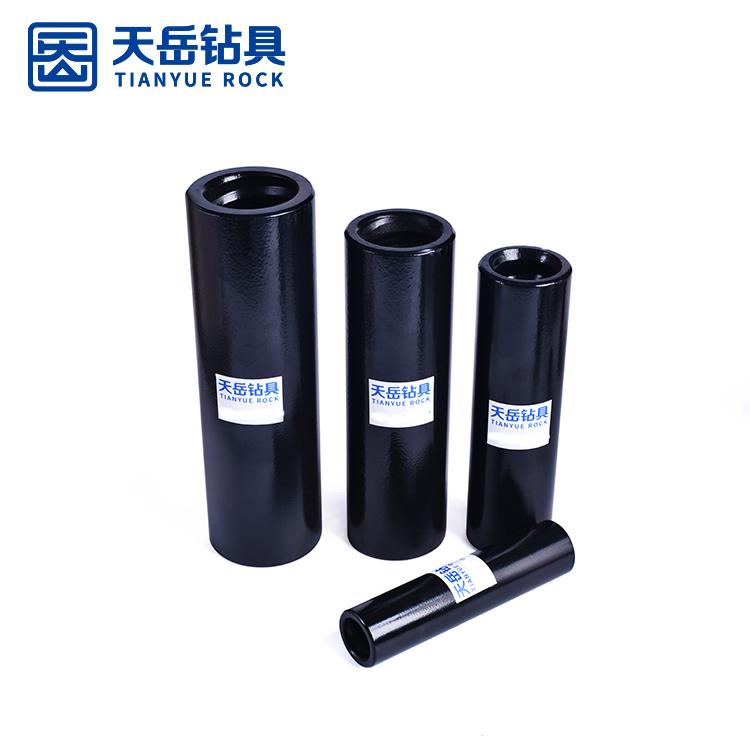

Coupling Type | Full bridge coupling sleeve

Reducing coupling sleeve(Ctossover couplings,Adapter couplings,Reduction couplings,Reducer coupling)

Standard couplings(Semi bridge couplings) |

Length | 150mm~235mm |

Diameter | 33mm~72mm |

Custom Design | Size,Color,Diameter,Thread,Length |

When it comes to rock drilling in the toughest conditions—deep mining, tunneling, or quarrying—T51 coupling sleeves are the invisible champions holding your system together. Engineered for strength, endurance, and seamless energy transfer, T51 coupling sleeves are an essential component of any efficient top-hammer drilling system.

In this article, we’ll explore everything you need to know about T51 coupling sleeves—why they matter, how to choose the right ones, and how they can dramatically improve your drilling performance while reducing long-term costs.

What Are T51 Coupling Sleeves?

T51 coupling sleeves are high-strength connectors used to join two T51 threaded drill rods or a rod and a shank adapter in top-hammer rock drilling systems. These sleeves ensure tight thread engagement, torque stability, and energy transmission from the drifter to the bit.

Made from heat-treated alloy steel and precision-machined to fit T51 thread profiles, T51 coupling sleeves are designed to withstand extreme pressure, impact, and wear.

✅ Key Function: T51 coupling sleeves securely connect drilling rods, allowing energy from the rock drill to pass efficiently through the drill string.

Why T51 Coupling Sleeves Are Critical to Your Operation

Choosing premium T51 coupling sleeves is not just a maintenance decision—it’s a productivity strategy. Here’s why they’re crucial:

🔧 Minimize Energy Loss – Tight thread contact improves percussive energy transfer.

💪 Increase Rod Life – Reduce thread wear by ensuring proper alignment and torque distribution.

🚧 Reduce Downtime – Durable sleeves lower breakage rates and drilling interruptions.

💰 Lower Cost-Per-Meter – Consistent drilling output with fewer replacements required.

For any contractor or mining operator, investing in quality T51 coupling sleeves means fewer rod failures, smoother operations, and ultimately, greater profitability.

Types of T51 Coupling Sleeves

There are multiple types of T51 coupling sleeves to fit specific drilling needs:

1. Semi-Bridge T51 Coupling Sleeves

Used for short-hole drilling

Offers easier alignment and thread engagement

Slight bridge keeps rod ends apart to reduce jamming

2. Full-Bridge T51 Coupling Sleeves

Common in deep-hole and high-pressure drilling

Ensures stronger torque transmission

Helps maintain rod stability in long holes

3. T51 Speed Rod Couplings

Each sleeve type is manufactured to exact T51 thread tolerances, ensuring compatibility with top hammer systems from brands like Atlas Copco, Sandvik, and Furukawa.

Applications of T51 Coupling Sleeves

T51 coupling sleeves are used across a wide range of demanding applications:

Their robust design and thread accuracy make them the go-to connector for high-pressure and high-frequency drilling systems where failure is not an option.

How to Choose the Best T51 Coupling Sleeves

Here’s what to look for when sourcing T51 coupling sleeves:

✅ Material Quality – Look for 42CrMo or equivalent alloy steels with heat treatment.

✅ Precision Machining – CNC manufacturing ensures tighter tolerance and better thread life.

✅ Thread Compatibility – Must fit perfectly with standard T51 rods and adapters.

✅ Surface Treatment – Phosphating or nitriding improves corrosion and wear resistance.

✅ OEM or Certified Aftermarket – Trusted suppliers will have quality certification and performance records.

Don't settle for cheap alternatives. Poorly-made T51 coupling sleeves lead to dangerous rod failures and costly delays.

Why Buy T51 Coupling Sleeves from [Your Brand]?

At [Your Company Name], we specialize in precision-manufactured T51 coupling sleeves designed for extreme environments and engineered to exceed international standards.

🔩 Why Choose Us?

🔷 ISO-Certified Manufacturing

🔷 100% T51 Thread Compatibility

🔷 Custom Engraving Available

🔷 Bulk Orders + Fast Global Shipping

🔷 Proven Performance in Over 30 Countries

Whether you’re drilling in granite, basalt, or limestone, our T51 coupling sleeves deliver unbeatable reliability and value.

Customer Testimonials

🗣 “We've tried multiple brands, but nothing beats the durability and precision of [Your Brand]’s T51 coupling sleeves. Zero failures in 6 months of continuous mining.” — Site Supervisor, South African Mine

🗣 “The threads fit perfectly. We no longer worry about rod slippage or sleeve fatigue.” — Project Engineer, Scandinavian Tunneling Firm